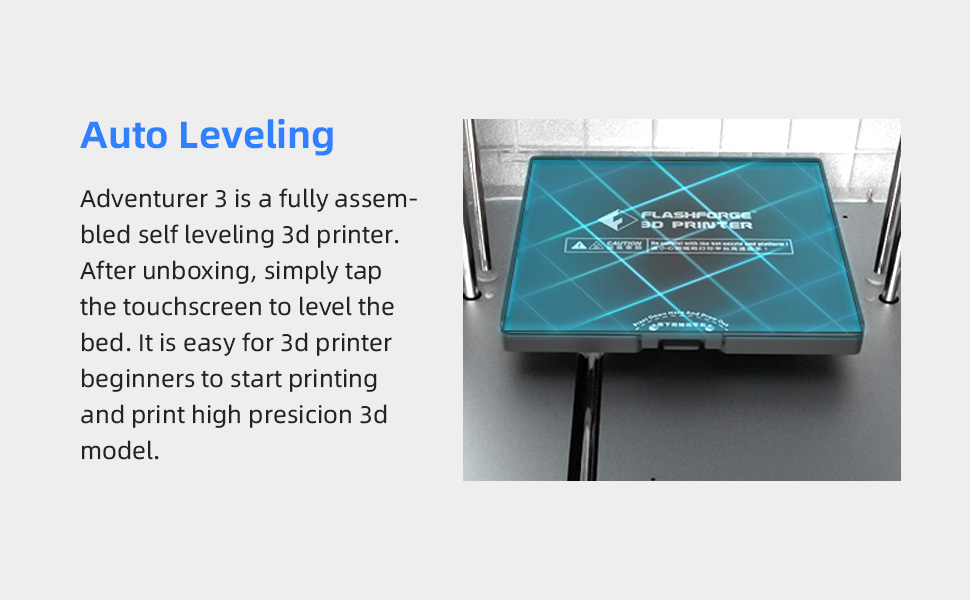

FLASHFORGE Adventurer 3 Enclosed FDM 3D Printer,with Removable Platform and Removable Nozzle,Remote Camera Monitoring,Filament Detection,Auto Leveling,Resume Printing and Mute Cloud Printing

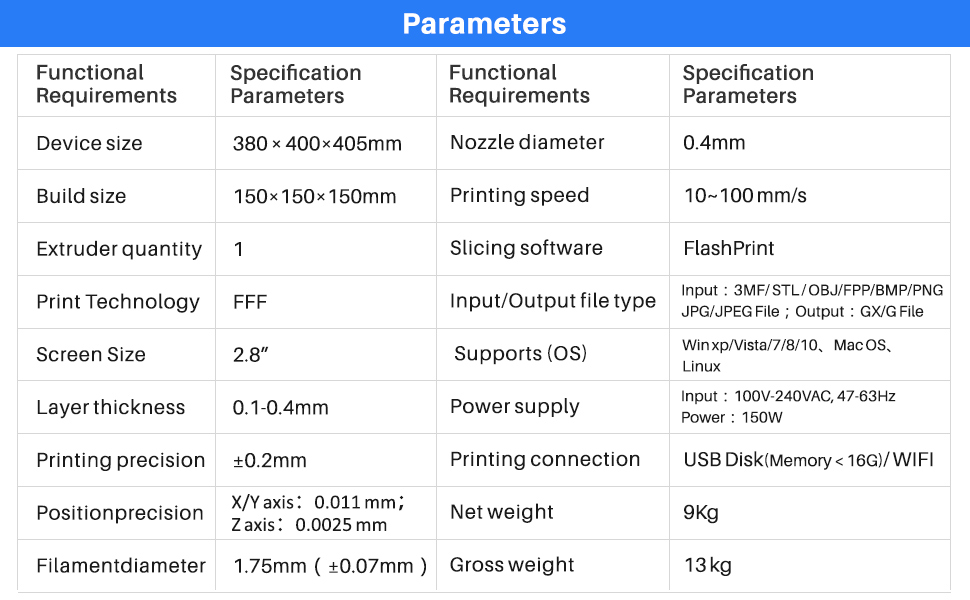

| Dimensions: | 38.8 x 34 x 40.5 cm; 12.28 Kilograms |

| Manufacture: | Zhejiang Flashforge 3d Technology Co., Ltd |

| Origin: | China |

| Reference: | AD3 |

This 3D printer is absolutely awesome. It can do so much.

Der Druck kam gut verpackt, berpnktlich bei mir an. Ich habe mich fr diesen Drucker entschieden, da er ein Gehuse hat und dadurch auch vor Staub geschtzt ist. Er hat keine Kamera, die ich auch nicht bentige. Ich bin 3D Anfnger und habe keinerlei Erfahrung gehabt. Ich kam mit dem Drucker sofort zurecht und die Druckergebnisse finde ich sehr gut. Das Mitgelieferte Filament htte etwas ppiger ausfallen knnen. Tipp, gleich Filament mit bestellen. Sehr schn ist auch das automatische Nivellieren der Grundplatte. Er ist auch sehr leise. Als Slice Programm kann ich nur das original Flashforge empfehlen, da z.B. Cura keine Files mit .rx erzeugt. Ich habe zuerst mit Cura gearbeitet, und mich gewundert, das auf dem USB Stick keine Datei gefunden wurde. Leider fehlt auch im Zubehr ein kleiner Spachtel, aber das kann man noch verkraften.

Being a novice, I wanted domething easy to set up and use. This little beauty did not disappoint.

Pretty much from setting up, I was printing project boxes, and other little items.

My only, minor complaint? The supplied filament is not enough. Luckily, I ordered a bundle with the printer.

I am newbie to 3d printing this printer is so easy to use and I love it I am absolutely obsessed printing the next print highly recommend this printer 10 stars

Ottima stampante, facile da utilizzare.

Basta toglierla dall’involucro, eliminare gli adesivi, attaccarla alla corrente e il gioco fatto.

Accesa, caricato il modello nel suo formato (.gx) attraverso il software flashprint ( o cura con l’add on x3gwritten), puoi direttamente stampare.

Non ha necessit di livellamento iniziale.

Il piatto stampa estraibile comodo perch in pei e non necessita di lacca per adesione.

una volta stampato il modello, questo di stacca facilmente.

Ottimo il display, semplice e carino anche a vedersi; ti mostra cosa vai a stampare.

Ottimo anche la possibilit di caricamento filo in automatico.

Interessante la possibilit di caricare bobine da 500g al suo interno.

Esteticamente la trovo bella e di design.

piccolo forse il piatto di stampa ( 150x150x150mm).

Les objets colle au plateau, et j’ai beau tordre la.plaque… a se dcolle pas?

Une.idee

Gestern Abend habe ich endlich mein AD4 erhalten. Und beim auspacken sehe ich einfach Das das Stromkabel was mitgeliefert worden ist garnicht fr EU Steckdosen ausgelegt ist. Heist man muss nochmal extra Geld investieren fr ein neuen Kabel. Finde ich echt schade. Es kann natrlich auch sein das es bei mir ein Fehler war. Mehr kann ich zum Drucker noch nicht sagen da ich ihn nicht in Betrieb nehmen kann.

Bought this because it was enclosed and I got cats. Sure enough, they like to watch the printing and I am sure they would try to attack the nozzle if they could. It is a very easy to use printer as well and quick to set up. No levelling needed. I am enjoying it and learning as I go along.

Ich wollte einen geschlossenen 3D Drucker fr Einsteiger und habe mich fr den Flashforge A3 Lite entschieden und bin zufrieden. Besonders positiv finde ich die geringe Stromaufnahme

If you are a Linux person, this company has the support. Just that alone was a plus. With all the add-ons mitigated me having to use a raspberry pi OctoPi. Great Printer.

Easy to use, without any calibration right out of the box. Good printing quality.

La stampante si presenta in una forma cubica molto intelligente, in quanto l’area di stampa completamente chiusa, il che contribuisce a limitare il rumore. Tra le tre che ho avuto sicuramente quella pi silenziosa.

Tra i pro pi importanti c’ sicuramente il piatto riscaldato ed estraibile, che consente allo stesso tempo delle stampe di buona qualit, e una maggiore semplicit nel distacco del pezzo, visto che non si deve armeggiare con coltellini e lame all’interno dell’area di stampa.

Il software relativamente basico, ma per me va meglio cos. La connessione al PC avviene attraverso wifi. Qui la stampante stessa che crea un access point al quale connettersi con il proprio PC e, attraverso il software in dotazione, lanciare la stampa.

Per quanto riguarda quest’ultimo non mi pronuncio troppo. io lo uso solo per la parte di slicing e stampa in quanto i particolari li creo con altri software.

In fin dei conti, la promuovo completamente. Per il prezzo pagato, credo, non potevo trovare di meglio

I love the printer so far! It’s easy to use, user friendly and prints in very high quality for this price range of printer. The built-in camera in cloud enabled functions are great!

I like it so far, its simple and it works. I calibrated the table with a piece of paper and fed it the stock filament and let it rip. So far it works. I’ll post photos at a later date to demonstrate the ease of use.

Very easy BTW even on Linux(Mint) The software was great right out of the box. I highly suggest it for younger kids if this is what they learn on from the start.

Honestly i will say, out of the box i have done over 500hours printing with little to no adjustments at all. i also have a professional $1800 printer that is rubbish. this flashforge has been my best purchase out of all my purchased products over the years. will be a forever flashforge customer..

Have had the Adventurer 4 for about 4 months and loving it! I upgraded from the Flashforger Finder because I wanted a larger build plate. Love the possibilities the Adventurer 4 gives me! It has been very easy to use.

-This wifi connection was iffy, even when i could see the printer on the cloud i could see it with my PC.(I’m assuming the wifi was a unit issue, or possibly software)

-The camera is very very low res

-The light is small, there should be a second LED inside the enclosure to improve image quality

-online slicer…is exactly what i expect from an online slicer

PRO:

-Hepa filter

-Build volume is good(large-ish)

-Yehey Bowden drive !!

-any camera is better than no camera 🙂

-Love the flexible removable bed

-for the most part prints stayed until you say otherwise

-print quality is good out of the box…tuning is always required…unless you plan on printing Benchys all day with the same filament same season and same time of day 🙂

ODD:

-its not silent – pretty quiet you wont hear it in the next room

-the keypad had a delayed reaction..so it was press…blink..select

-I liked the enclosed spool

– a scraper/spatula(for residue and retraction lines) .stl would have made my day.

ADVICE:

-note i returned because the wifi was erratic with my pc, and personal preference …I realize i will print alot of large projects, and a z-drive will just suit me better, especially if the supports are on the edge of reasonable.

if you are not going with any soft filaments(TPU). and you need an enclosure, and the xyz is your style i would recommend this. Is it pricey? im not sure, i paid the extra 50 and bought the older brother (GUIDER 2)

Auspacken und sofort loslegen. Die Software ist einfach gehalten aber fr Anfnger perfekt (MAC). Ich kann diesen Drucker nur empfehle

The 3D printer is great but the test filimant that they send keeps on breaking inside the machine causing faulty prints. Also the casing only supports 500g of filimant and anything larger then that the wheel is too big. All in all this is a good printe

Setup was mostly painless, which leads to why I did not give it 5 stars. I could not get the wireless to connect to my network even though my AP was seen and had full signal. I read another review elsewhere where the person also could not get the wireless to connect.

Connected to my wired network and it works great, even the built in camera was now accessible.

Installing the filament was also very easy.

First print went very well and I was pleased with the print quality.

I think Flashforge has a winner with this printer. I hope they offer a fix for the wireless issues.

Really good value for money easy to use, but remember the spools are smalle

I work in IT and network security for me is huge, so I choose to only connect this printer via WiFi for updates. I don’t use their cloud features but it’s available. The quality between the finder and adventurer 3 cannot be compared as Adventurer 3 blows it out of the water. I will be adding 3 more Adventurer 3’s to my business soon. The adventurer 4 is on my list to buy but at $800 retail it’s too pricey for me.

Overall great product and would recommend! Keep in mind if you plan on printing as much as I am, you’ll need a new hotend every 3-4 months to maintain quality and consistency. If you’re just getting into 3D printing the hot-end could last you years. I print roughly 16 hours per day, sometimes 24. The hotend is so easy to replace and doesn’t require special tools.

I recommend Flash Forge to everyone wanting to start in 3D printing and my family. It’s worth every penny and I could see this printer lasting me 10,000+ hours of use.

Well packed and works straight out of the box without any tinkering. Test file was printed literally after taking it out of the box and pressing go on the pre-loaded test file after loading the filament. No need for tuning/alignment etc as everything seemed square.

Came with some tools as pictured and 250g of filament in the box to play with. Flex gecko was easy enough to print after downloading model and putting it into Flashprint to print (with rafts turned off).

Its a great beginner’s printer for those who just want to print instead of tinkering with their machines. The spring loaded built plate is also pretty easy to use.

This thing is fantastic. It takes longer to get it out of its packaging than it takes to get it up and running.

The heated bed is great and promotes good adhesion and helps with warping of parts. The bed comes with some kind of permanent textured surface so you no longer have to mess about with masking tape or other temporary bed covers that must constantly be renewed. The machine is quiet. It has a built-in camera so you can monitor print progress remotely, if desired (I have not tried this yet). The device has built-in wifi capability, and using the FlashPrint software you can easily import .stl (and other) files, slice them, and then push them wirelessly to the printer, whereupon it will start printing. The software has very fine control capabilities but honestly the Basic setting works just fine for what I’ve done so far. Print quality is great for my parts – so much so that I now print on Fast setting because it’s plenty good enough for the parts I am making. Standard quality was fantastic. I should print something on Fine just to see how good it can actually get.

About the only criticism with the machine is that it won’t accept 1Kg spools. But that is OK – simply remove the access panel and set your spool on a spindle rod right beside the machine and it will up-take from an external spool just fine.

Also the machine has a fantastic auto-load and unload routine that makes changing filament painless.

I can’t imagine how you could get a better machine for the money. I’m tempted to buy a second one just to increase my production speed.

Side by side comparisons of “benchy” test prints on my PRUSA MKS3+ and on the FlashForge Adventurer 3 Lite were remarkably similar, in fact I would give the edge to the FlashForge Adventurer 3, which in and of itself is amazing! My test prints were done using the very same roll of PLA white filament. Both printers were using .4mm brass nozzles and printing at a height of .2mm. All heat settings were identical and the gcode only differed on model. Retraction, speed, etc, all the same.

The FlashForge Adventurer 3 Lite has a lot to like about it and something that was a good idea but poorly executed, hence, the 4 star rating. It is super easy, out of the box to set up. I think it took me a total of 15 to 20 minutes to unbox, level the bed, configure the settings using the nicely laid out display and I was up and printing.

This is a great printer for the beginner at not such an entry level unit but finally a consumer friendly unit that won’t collect dust like some of the other FDM printers which become frustrating and intimidating for some. The FlashForge Adventurer 3 Lite is 100% user friendly.

The display is outstanding and set up well and very easy to understand.

I almost forgot to mention sound, this is quieter than my dishwasher, which is ~44 db. So quiet that I can finally keep a printer in my bedroom without bothering my wife’s sleep.

The only shortcoming and disappointment to me is the compartment that holds the filament spool. What a great idea having everything all enclosed! This was a strong selling point for me. But as it turns out the opening is not standard. It will not fit the standard 1 kg spools. It does not even fit the .5 kg spools that I have; those are close. What I did get to fit inside was a .4 kg spool, which is not a lot if filament but it seems to work size wise. Unfortunately, I have most of my PLA in 1 kg rolls, which means that I need to leave the filament door open when I print. I was unable to obtain any clear information on what size spool actually fits this printer. Seems like the idea was there, but the size was an afterthought. Maybe the next version will have it. For now it is definitely not a show stopper, but it does require a little more space to operate like this.

Overall, this is a great consumer friendly printer and certainly has way more pros than the one con that I found. I would highly recommend it to beginners and intermediate users. It is great to have everything all in one and it is also cool to watch from all sides!

The FlashForge Adventurer 3 Lite is in a price range and size that makes it a good choice for beginners or for those that don’t want to build. Most of the printers in this price point require assembly by the user. For most, new to 3D printers, this one comes out of the box. Remove the protective rapping and shipping pieces and it is almost ready to print. By following the included instructions, this printer will be up and running in 15 minutes or less.

It comes with FlashPrint, the software to slice STL object files. It works well, but for those familiar with 3D printing, might be disappointed. It doesn’t allow or have some of the features in other mainstream slicer programs.

What this version of the Flash Forge doesn’t have include the video camera, or a filament out sensor. Maybe a beginner doesn’t need them, but having them would have made this a much better printer.

The print quality of the little printer is second to none in this price range. Prints come out really nice. Prints can be removed nice and easy with the included flex bed.

Note that this printer can only take filament rolls of small size, 500 grams or less.

All in all I am enjoying this little desktop size printer.

Straight out of the box you can tell its well packed and secure.

Comes with a few small tools and a bit of grease for lubricating but it only needs a tiny bit – don’t overdo it.

Follow the set up, load the reel of red Flashforge filament and you’re ready.

There’s a small test cube already loaded on to try.

I wanted to run this without any form of calibration and it takes about ten minutes to print.

Absolutely no problems at all!

Then I loaded a nine point calibration test, once again without any form of set up by me.

This was really good. Adhesion was good and each layer went down well.

The third print before running my own was the nozzle tool also installed.

Nice print, good layers and a clean surface.

I must admit I had one of these when they very first came out and I was equally impressed by it then.

Currently that one is over 600 hours and still on the original nozzle and bed.

Spare beds and nozzles are available including the newer 265c nozzles.

Have printed ABS, TPU, PLA, PLA+ AND Petg. They all need setting up to do but they are all possible on this excellent machine.

I really believe that with Flashforge you get quality.

All my flashforge machines have been easier than the Ender 3, which took a while to setup and get any decent prints out of.

If you buy this I’m sure you will be happy with it.

Happy Printing!!

It was a little bit of a chore setting it up and calibrating it to begin with. It says auto calibrating but it didn’t feel very automatic to me. Took several minutes. Once we got that done we fed the included printer filament thru til we saw it coming out the end. It got caught up once but we quickly got it going thru just fine.

We printed the little 3D demo cube that’s programmed in and it printed it flawlessly! Then we got a file for a jack o lantern pumpkin and put it on a jump drive to try that. We had to take the drive back to the computer and convert it to the right format so the printer could use it but other than that- it printed our little two piece jack o lantern in about 1.5 hours. The teeth of the pumpkin had some extra filament goo hanging from them but we just took a craft knife blade to it and cut off the excess easily.

Overall we’re very happy with our first 3D printer! It prints really well and is a lot of fun! No real assembly required which is great for a beginner. My complaints are that the tip is built in so you can’t just change the tip out like others. The parts are a little pricier for this than others as a result of the way they made it but not so outrageous you can’t afford them still. Of course the print bed is pretty small on this one but that’s ok for our first printer, we’ll upgrade to a larger one later and use this for smaller projects.

6 WEEK UPDATE!

Okay, since getting the Adventurer 3 Lite I’ve acquired an Ender 3 and a Neptune 2 – and the Adventurer is my favorite. Its just so incredibly easy! This comes at the cost of being able to make any modifications, but its reliable and hassle free in return which makes it a worthy sacrifice. Performance has been completely flawless especially after I printed a filament cover extension that snaps onto the frame (no glue, no nails, completely non-destructive) and uses the existing cover as a hinged door to the filament compartment.

FILAMENT SPOOL EXTENSION AND COVER:

A lot of people consider the lack of a 1kg filament spool capacity a deal breaker and thats a shame. I found a design on Thingiverse that allows the use of 1kg spools of filament without having to drill a hole or make any modifications to the Adventurer, while also allowing you to keep the enclosure closed and better able to regulate temperatures during prints. Furthermore – it provides a very smooth and friction-free filament feed that doesn’t strain the extruder – ie no thumping or knocking sound during prints. The knocking during prints is a common complaint among Adventurer 3 owners, but its completely eliminated with the cover and spool extension. I’ve never had to deal with it since making the cover.

FILAMENT SPOOL EXTENSION AND COVER:

If interested in printing a 1kg filament spool extension and frame for the cover, search Th*ngiverse for “Adventurer 3 Filament Spool Box version 2”. The design consists of three pre-arranged .stl files or you can print them all individually as you please. I printed the three pre-arranged files, with 55% infill (waaay overkill, easily 20% would have been fine), black and signal white Tinmorry PLA (total about 1.5kg filament used), for a total print time of 60 hours give or take. So worth it. And yes, it was printed with the Adventurer 3 Lite.

UPDATE (after two weeks of running it 24/7):

I’ve owned the A3L for two weeks now, during which I’ve been printing literally 24/7. I’ve had successful prints with every material I’ve thrown at the Adventurer. For most prints I have found that the stock settings in FlashPrint work best, which is a nice surprise. I found reddit to be my best friend when troubleshooting, which makes things easy with this printer.

* TPU = yes! (settings: temp=240c/50c; print speed=17mm/s; travel speed=150; infill 100%;layer=0.20mm)

* ABS = yes! (requires 265c nozzle; default settings in FlashPrint)

* PETG = yes! (default settings in FlashPrint)

* PLA/PLA+= yes! (default settings in FlashPrint)

* PLA-CF = yes! (default settings in FlashPrint)

* PC = yes! (default settings in FlashPrint)

WHAT’S IN THE BOX:

* Adventurer 3 Lite 3D printer.

* 0.1 Kg of transparent red PLA filament (enough for several small projects to get you started)

* AC power cord.

* Quick start guide.

* Grease.

* Sharp metal pin tool for resolving a clogged extruder nozzle.

* Allen wrench.

* Screwdriver.

EASE OF USE:

Unlike some of the other entry level printers, the A3L arrives completely assembled. All you need to do to get started is take it out of the box, remove the blue tape from the outside of the printer, plug it in, flip it on, move the platform forward to release the protective packaging materials from the inside of the printer and then remove them. That’s it. It really couldn’t be any easier.

Once you’ve done that all you need to do is connect to the printer one of three ways:

1. WiFi. (doesn’t work)

2. USB stick. (doesn’t work)

3. Ethernet. (WORKS)

4. Hotspot. (WORKS)

WIFI ISSUES:

For whatever reason, I was unable to connect the A3L to any of the WiFi networks that I tried. I tried both 2.4Ghz and 5Ghz networks, and the connection always failed. I did some googling and it turns out a lot of people seem to have difficulty getting the FlashForge Adventurer 3 series connected to WiFi for unknown reasons.

USB ISSUES:

I formatted a fresh USB drive and transferred my print files over to it before plugging it into the A3L, but this method didn’t work either. I tried formatting a few other USB drives to see if I could get a different result, but like WiFi, it just didn’t work and I have no idea why.

HOTSPOT:

The A3L also comes withe ablity to connect to it via hotspot. To access these settings go to Network Settings, select WiFi and choose hotspot. From there you’ll be shown a screen with the default Hotspot name, password, and IP address, as well as a toggle to turn the hotspot on, and a setup button to customize the hotspot name and password.

The hotspot connection works well, and I was able to easily connect my Windows 10 PC to the A3L in order to upload print jobs. That said, using this method for connecting to the printer seemed to interfere with my computer’s internet connection for some reason, so don’t use it and instead use the hardwired, ethernet port for connection most of the time.

ETHERNET SUCCESS:

Luckily, the ethernet port located on the back of the A3L ended up working, and has since provided a reliable and consistent connection to the A3L from my Windows 10 PC. Using this method from the FlashPrint software from FlashForge, the A3L is automatically detected and connected, allowing me to send prints this way. Once the print files are transferred to the A3L they are stored locally so you don’t need to keep your computer running while you have something printing.

SOFTWARE:

Since I’m new to the 3D printing, I’m not well versed in the many different software options available, nor which of them are compatible with this printer. FlashForge has their own simple software called FlashPrint that I downloaded from their website and have been using ever since. The software is simple, and defaults to a Basic mode that really simplifies the options you need to worry about when selecting files that you want to print. If you want more options, you can choose to use the software in Advanced Mode, which reveals more granular settings like layer height, support structure settings, fan settings, rafts, brims, resolution, etc.

The software is very easy to use, seems free of bugs, and makes it easy to get files from Thingiverse uploaded and ready to print. The software/printer accepts the ubiquitous .stl file format, so I have yet to come across a print that wasn’t available in a compatible file format.

I believe the following file types are supported:

*.fpp

*.stl

*.obj

*.3mf

MAX RESOLUTION & SPEED:

* minimum layer height = 0.01mm

* minimum speed = 10mm/s

LIMITATIONS:

From what I’ve read online about this printer, the range of options and configurations available on the A3L is somewhat limited. Advanced or seasoned users will probably find this frustrating, but I don’t think that’s the target demographic for this little guy. But its worth taking into consideration if you’re the type of person who wants more control over their prints since there are more appropriate options out there for you.

Limitations that I’ve noticed so far include there being only two different support structure styles available (linear and tree), and only a handful of infil patterns to select from.

But for someone like myself, who is just getting started on their 3D printing journey, the A3L is perfect!

PRINT QUALITY:

So far my prints have turned out really well. For example, my photos show “Friendly Articulated Slug” printed in translucent PLA using close to default print settings (I just slowed down the print speed to 40mm/s from the default 60mm/s), no supports, raft or brim, and it turned out perfect on the first try! The print took around 5 hours to complete.

On another print I made, I encountered a problem about 1/3 of the way into the print where the print lost bed adhesion and had to be trashed. A quick google revealed that increasing the print bed temperature a little could help by increasing the adhesion and sure enough – it did. Running into little problems like this isn’t a big deal since there is such a wealth of information available online to help you.

I haven’t experienced any problems with removing prints from the print bed after they’re done printing. I just take a metal pick and gently work it in under the edges in a few places which usually releases the print from the print bed surface. The print bed slides out making it easy to remove your prints.

INTERFACE:

The A3L contains a full color, LCD touch screen interface that allows you to change settings, swap filament, connect to networks, calibrate the print bed/printer, and preheat the extruder. The interface is easy to navigate and doesn’t require you to keep the manual handy for deciphering menu options which is nice. The touch interface is responsive enough to make it useful and not annoying. Color and brightness are all very adequate and provide excellent visibility from a wide range of angles. During prints the screen displays the file name of the print job, a small picture of the print, time remaining, and print controls: stop, pause, and the ability to swap filament mid print.

FILAMENT COMPATIBILITY:

The A3L ships with a Bowden extruder (I won’t pretend to know what that means but apparently it means something) and a nozzle that is capable of a maximum extruding temperature of 240 degrees Celsius. From what I read, the Bowden extruder might be a limitation with regards to being able to print with either TPU or PETG filaments, but I also read alot of accounts where people were able to print with those with any trouble. Just receieved some PETG and TPU so I’ll update this review to include my own experiences soon.

ABS:

The nozzle that comes with the A3L has a maximum temp of 240C, which means you won’t be able to print with ABS filament unless you purchase the optional high temp nozzle. The high temp nozzle is only $30 on Amazon, so its an easy upgrade if you’re interested in printing with a wider range of filaments like ABS. The nozzle is a quick swap style making for an easy, no-brainer upgrade in my opinion.

OTHER THINGS I LOVE ABOUT THE A3L:

This is a ridiculously quiet printer. Okay, save for the stupid and obnoxiously loud little jingle it plays upon startup, its otherwise quiet as a mouse.

I also really love the fully enclosed design. I have the printer sitting on a table that is right next to my portable air conditioner. An open frame design would be impossible to use for me since I have nowhere else to put a printer. But the enclosed design allows the printer to maintain its internal temperature while printing, making it easier to find space for use overall. It also keeps dust away from the internals, keeping things clean and easier to maintain over time vs an open frame.

THINGS I DON’T LOVE:

As others have mentioned, this printer includes an internal filament spool on the right side of the printer which is a cool idea if you don’t plan on using anything bigger than a 0.5kg spool of filament. But most of us are going to end up using 1kg spools since they’re more cost effective and easier to find, which means they don’t fit inside the A3L’s filament compartment. This isn’t a huge deal, but its definitely annoying to have to figure out a solution. You can always just leave the side door off and lay your 1kg filament spool on the table while printing, but that’s a pretty inelegant solution.

I solved this problem by drilling a small hole in the compartment door through which I feed the filament that is sitting in a dryer box next to the A3L. This allows me to keep the compartment door closed, which allows the printer to maintain temperature control while printing.

Others have taken to the approach of using this as an opportunity to make their first print a filament holder that either stands next to your printer and holds a 1kg spool for you, or a spool holder that you screw into the side door, or going as far as printing a new door that will accommodate a 1kg spool of filament. The choice is yours, but chances are you will have to make a choice on the matter. Annoying, but whatever.

And of course, the quirks regarding my inability to connect a USB stick or connect the A3L via WiFi are not insignificant either. I’m hoping this is something that can be ironed out with a firmware upgrade from FlashForge so I’m trying to be a little forgiving in this respect since I still have full printer functionality via Ethernet.

BOTTOM LINE:

I was worried that 3D printing would be accompanied by a steep learning curve littered with troubleshooting and frustration – but the Adventurer 3 Lite has been extremely user friendly and accessible. I was up and running with my first print within an hour having the A3L delivered and unboxed. Print quality has been outstanding, and the wealth of information available online makes it easy to learn things as I go.

While this printer isn’t without its problems, its thoroughly exceeded my expectations for what an entry level printer like this can accomplish. Price seems very competitive for the feature set and ease of use that comes with the Adventurer 3 Lite.

photo notes:

* Red skull printed using 100% default settings, no supports only raft, no post processing after raft removal. Filament used is what is included with the A3L. Files found on Th*ngiverse.

* Slug printed using transparent PLA filament at 40mm/s, no supports, no raft, no brims, 15% infill, zero post processing. Files found on Th*ngiverse. Filament: https://www.amazon.com/gp/product/B093BNVK58/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

The great thing about this printer is that right out of the box, you can set it up and be ready to print in just a few minutes.

It’s hard to evaluate any small 3D printer without comparing it to the ubiquitous Ender 3. But this printer has both advantages, and disadvantages in that comparison. And, to a degree, that’s a matter of perspective.

If you just want to be able to print small models and parts out of PLA and ABS, don’t need to print exotic materials like carbon fiber filled nylon, don’t care what slicer software you use and pretty much want your printer to be an appliance rather than a hobby, this is a great printer!

Another good comparison would be the difference between buying a bunch of parts and building your own drone versus buying one that you charge and go fly. This printer is super user-friendly, and most of the guesswork and tinkering is taken out of the equation so you can just load the files and print them… super easy.

That said, if you already have another printer with the settings dialed in, and know how to get good quality prints from it, this isn’t going to add that much functionality, and you’ll probably have a smaller build space to work with.

So, the number one biggest downside to this printer is the filament spool situation. The printer has a really neat design that allows you to mount the filament spool inside a panel on the side of the printer and keep it enclosed. This helps keep the filament from absorbing moisture while you print. And it keeps the filament from getting snagged by curious cats, and any manner of other things that could cause a print failure. But, there’s a big downside to it. Filament is typically sold in 1Kg spools, and the spools that fit this printer are smaller. You can buy the correct size spools from the manufacturer, but that limits your filament choices and your ability to shop for the best price for filament.

I ended up using my filament dryer as a dispenser and that worked okay. (See the pictures.)

Another solution that will work is to simply reload your filament onto smaller spools that will fit, and there are even printable spools that can be printed in several parts and assembled, and you can print these using the Adventurer 3 Lite. I’d just get the first spool from Flashforge, print a spare spool, and then reload those spools from the 1kg spool of your choice.

The nozzle design is another one of those things unique to the Adventurer 3 series printers that has both good and bad aspects. It’s designed to be very user friendly and easy to change. You basically just “unplug” it from the print head. If you ever need to change a nozzle, it’s going to be very easy. But, a new nozzle for this printer costs many, many times as much as new nozzles for conventional printers, albeit with a bit more complicated process to change them.

Connecting to the Wi-Fi network at home took a few tries working with the touch screen because I have fat fingers. The first thing you should do after connecting is to update the firmware. The printer will find and download the update without needing a computer connected. After that, you can connect to the printer with Flash Print (the slicer software). I wasn’t able to auto detect the printer, but you can get the address by tapping the Wi-Fi network name you connected to on the screen, and it will display the address. Then type this into the slicer and off you go.

Slicing is very simplified compared to a full-featured slicer like Cura, but that’s probably a good thing if you are new to printing. The best part was wirelessly sending the file to the printer and watching it go to work without having to push any buttons on the printer at all. This is a real treat.

So after all that, how does it print? So far, so good, but with a little snag. The extruder makes a loud “popping” sound when it skips. I noticed that this occurs only when the printer is laying down a solid layer (like when printing a flat surface at 100% infill. Here’s what I think is happening… The slicer (Flash Print) isn’t configured to slow the feed rate in this situation, and the extruder is pushing filament faster than the nozzle can lay it down. I noticed that the “standard quality” setting in the slicer uses a 0.18 layer height by default. I changed this to 0.20 (to match the layer height Cura uses for standard quality with a 0.2mm nozzle) and will try again to see if that corrects the problem. I know it’s not the spool jamming because I gave it plenty of free slack of filament and it would still skip, but only when laying down a flat 100% infill. I really think the solution here is going to be increasing the layer height so the filament has someplace to go as it comes out the nozzle. As long as changing this doesn’t increase the extruder speed automatically in the background, then it should work.

After printing a second batch of parts at 0.20 layer height and less than 100% infill, I experienced no extruder skipping. I also made sure to go through the bed leveling routine before the second batch.

There is a little noticeable “ringing” on parts printed at standard quality, but you can lower the print speed to correct this. I wouldn’t worry about it unless I was printing something that needed to look very accurate.

The flexible bed is great. Cleaning it with 90% isopropyl alcohol before printing gives excellent adhesion. And the ability to flex it and pop the prints off makes removing stubborn prints easy. I also really liked the lighted hot end so you can see the print better.

Overall the standard quality print has a good surface finish and the convenience of this printer is definitely quite a bit above the kit built printers. I do wish there was a Cura profile for it to allow more control at the slicing stage, but this is still a great first printer for the casual user who just wants to be able to print PLA and ABS at home.

The printer comes with everything that is needed to start 3D printing, except for the free 3D software that is needed to convert models to a code that the printer can read. There is even a sample of PLA filament included that you are able to use to run the machine. I was disappointed that the listing says that “One spool of filament is included”, and it even shows a picture of a full spool, but they only included a small sample of filament. Since I have plenty of filament this is not a big deal, but they should correct the listing since it is misleading. The included quick start manual walks through the initial installation of the printer and the printing of a model; however, it does not explain all of the printer’s functions. A more detailed manual is available on Flashforge’s website.

Setup of the printer is as easy as taking it out of the box, plugging it in, turning it on, raising the Z-axis so that the protective packaging can be removed, and you are all done. One step that is not covered in the quick start manual, but that is important, is calibrating the build plate. This process ensures that the build plate is level with respect to the nozzle. It is an easy procedure that I encourage you to do before doing your first build. I also recommend periodically rechecking the calibration.

To operate the printer, you must install a program that creates the actual program code that runs the printer. Flashforge has their own software, Flashprint, that is available for free from their website. The printer’s operating manual does not really provide any information on using this software, but I did find that one of the manufacturer’s videos in the Amazon listing to be helpful. It walked through the basics of using the software, along with providing some printer information. Additional software information is available on Flashforge’s website.

The printing process is straightforward. Load (if not loaded already) the filament, then either load the model onto the printer using one of several wireless methods (e.g., WiFi or Hotspot) or insert a USB drive with the file on it into the USB connection, select the model to print, then print. After heating up the extruder and the build plate, the printing process begins. There are several data points available to view both before and during printing, such as time to complete, estimated filament to be used, and extruder and build plate temperatures.

There are a few items that I do not like with this device. The first is the touchscreen. I have trouble getting the “back” button, located on the very bottom of the screen, to activate. Either the touchscreen is having problems, or my fingers are too big to activate that button. I also do not like that the filament holder will not hold 1kg or 2kg spools. While it has a 52mm hub, the diameter only measures about 185mm, and the depth only about 64mm. It appears that this setup is for 0.5kg spools. I will definitely be looking at alternate solutions to filament feed since I will not order these small spools. The last thing that I do not like is that the nozzle is a proprietary part, so the nozzle cannot be replaced with low cost nozzles, but it must be replaced with a Flashforge nozzle assembly that is expensive.

Overall, I am happy with this 3D printer. It is very easy to use, which is great for novices, yet it seems to be as capable as any other similar printers out there.

I have 2 Ender 3 printers, so I wasn’t sure I’d like this printer. But we’re making some changes to our hobby space, and a self-contained unit has a lot of advantages over the open Ender design, so I figured I’d give it a try.

TL;DR: I love this thing. There are a few minor flaws that make it 4.5 stars, but that rounds up to 5.

First, I love that it works out of the box. I went from the box arriving to starting my first print in 10 minutes, and had the print in my hand 10 minutes later. You almost don’t need the quick start card, it’s so simple. On-screen instructions walk you through every step.

The performance puts the “flash” in FlashForge! It heats up in less than a minute. The WiFi is solid, so even complicated designs can be sent almost instantly. This is truly “on a whim” 3D printing.

There are a few small issues worth mentioning. Nothing that would change my mind, just things I wish I had known beforehand.

*The build area is small, about 6x6x6 inches. I use it to make gaming minis, so that’s fine unless I need to build a dragon.

*The filament container doesn’t hold 1Kg spools, you need 500g spools. That makes buying filament less cost effective unless you buy big spools and wind them onto smaller ones (there are easy instructions online, but it is still a hassle).

*The beeps are LOUD and piercing. I’ve never felt like wearing hearing protection to operate a touchscreen before. If it’s in the house, don’t use it after bedtime.

Also, note that this is the Adventurer 3 LITE, which has 2 fewer features than the Adventurer 3.

*No camera to watch your prints, which I really don’t care about.

*No filament runout sensor. This can be a problem on large prints, especially with the small spool size. If you’re worried about not having enough filament, you’ll have to hang around while printing. You can pause the print, change filament, and restart (there’s a simple way to do so in the pause menu), but you have to make that decision manually, there’s nothing there to help you.

I’m really happy I picked this up, and am looking forward to using it for a long time.

I am impressed by the quality of this printer and the ease at which it can be used. This is certainly a great printer for beginners, but it is also a great printer for anyone. I have four 3D Printers (including this one) and have been printing for over three years. I consider myself experienced and I am extremely pleased with this printer.

The printer came packaged well. It took a few minutes to open but not too long to get it set up and printing. After getting everything ready, I put the included filament into the side and loaded it through the easy-to-use touch screen. It only takes a few minutes to figure out the menu. The getting started guide is easy to follow and walks you through the necessary steps.

Next, I followed the steps to level the bed. The description of the printer states it has auto-bed leveling. I am not quite sure I would qualify this as ABL. It uses a manual mesh leveling process which is easy to follow. The firmware takes eight measurements, three in the back, two in the middle and three in the front. I used a piece of printer paper to measure the gap between the nozzle and the bed to get the z-offset right. At each measurement point, I had to adjust the z-offset via the touchscreen. The process is tedious, but easy non the less.

A test print of a small cube comes loaded in memory (which is 8GB). I selected this to print. The hot end and bed heated up fast. The touch screen displayed the progress while it heated up and while it was printing. This print completed perfectly with no issues.

After my first print I connected a network cable to the LAN port and then registered the printer for the cloud service. It took a couple of tries to register. The web site will send a code via email and gave me 60 seconds to enter the code. At least twice the code came after the timer expired. The cloud software is easy to use. I loaded an STL file of another, larger test cube and printed it using the default settings. This cube printed perfectly.

The first printer I ever used was a FlashForge Creator Pro using the FlashPrint software. The cloud software replicates the basic mode of FlashPrint. In fact, this may be the only software you will need to use with this printer, however, if you prefer more advanced control, you can download and use FlashPrint.

I proceeded next to disconnect the LAN cable and configured the Wi-Fi adapter. My Wi-Fi passphrase contains complex characters. The Wi-Fi configured and worked without any issue. With the printer on the wireless network, the cloud software continued to work just as well.

I found the bed was easy to remove. It flexes easily and the prints detach without any effort. I prefer to use glass beds on all my printers, but this bed is impressive.

Everything about this printer is well done, high quality and just easy to use. If you are a tinkerer looking for a printer to upgrade and modify, you might not like this one, but if you’re just looking to print, this is a great option. Having said that, I took the bottom cover off to examine the system board and found a few extra ports including a serial port, camera port, door sensor port and a filament run out sensor port. If you wish to tinker, there are a few things that can be added. A 265 nozzle can also be purchased to use filaments that require a higher temperature. The nozzle is easy to exchange.

One issue I have with this printer is that a standard size roll of filament cannot be used inside the door. Standard rolls need to be put on some type of holder and fed though with the door removed. If this is your only printer, then this is not an issue at all. Simply purchase the correct size roll. When you have other printers, you will most likely have larger rolls you wish to use with this printer.

Another potential issue is that parts for this printer are specific this model. Replacements must be purchased from FlashForge or from an authorized reseller. This typically makes these parts more expensive. In addition, the nozzle is very specific, and a replacement nozzle is about $20 US. A replacement nozzle for most 3D printers’ cost under a $1 (they typically come is counts of 10 for a few dollars).

Overall, this is an excellent printer, and I can highly recommend it, especially if you are looking for a high-quality printer that is simple to use.

UPDATE [8/18/2021]: Picked up the higher temperature nozzle from Amazon. I am now printing flawlessly with ABS. The very first print came out absolutely perfect!