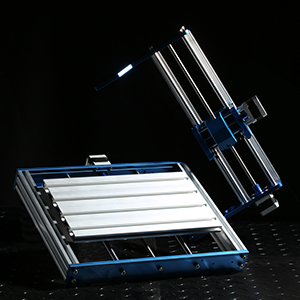

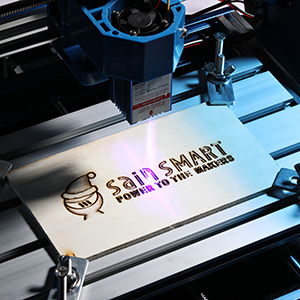

SainSmart Genmitsu 3018-PROVer CNC Router Machine with GRBL Offline Control, Limit Switches & Emergency-Stop, XYZ Working Area 300 x 180 x 45mm

SainSmart Genmitsu 3018-PROVer is the successor to the 3018-PRO, and the new version has brought improvements to many parts, including the excellent design and safety features, pre-assembly, upgraded mainboard, etc. Whether you’re a CNC beginner, a hobbyist or a small business owner looking for an enterprise-quality for commercial purposes, this is an excellent choice.

SPECIFICATION:

| Effective Engraving Area | 260 x 155 x 35mm(10.2 x 6.1 x 1.4”) |

| Frame Size | 400 x 330 x 240mm(15.7 x 13.0 x 9.4â€) |

| Frame Material | Aluminum |

| Z-Axis Component Material | ABS |

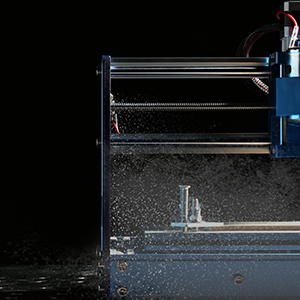

| Spindle | 775 motor, 12V~24V, 10000 RPM |

| Rated power | 60W |

| Maximum power | 120W |

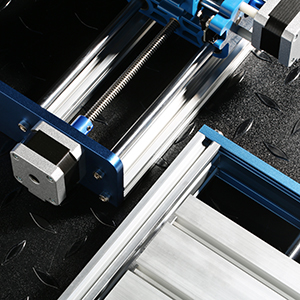

| Step Motor | 1.3 A, 12V, 0.25 Nm torque (2.2 in-lb) |

| Drill Bits | Tip 0.1 mm, 20 degrees, Diameter 3.175 mm |

| Supported OS | Windows XP, Windows 7 32/64 bits, Windows 8, Windows 10, Linux, MAC OS |

| Software | Grbl control(Candle) |

| Power Supply | 24V/4A |

| Great for | Hobbyists, Crafters, Woodworkers, Industrial Designers, Educators, Engineers, Jewelers and more! |

| | | |

|---|---|---|

Efficient Pre-assemblyThe 3018-PROVer is the newest addition to the Genmitsu CNC 3018 series family. This pre-assembled desktop CNC machine allows you to be up and running in 15 minutes instead of 2 hours, making it no challenge for beginners. | High QualityBoasts an all-aluminum body with an oxide blue look, the 3018 PROVer gives you a premium look and feel for your machine. | Safety DesignThe 5mm acrylic baffles can block the ‘flying’ pieces of wood/other cutaway materials so that you can safely monitor the engraving process. |

| | | |

|---|---|---|

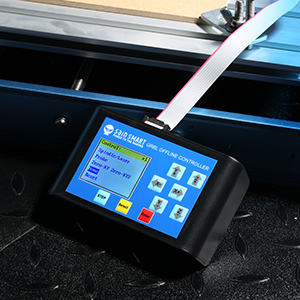

Offline Controller with 1.8″ TFT LCD DisplayThis machine comes standard with a newly designed offline controller with 1.8″ display so you can view readouts clearly and control the CNC router without connecting to a computer. | Laser Module AvailableIf you are an experienced CNC engraving enthusiast looking for an upgrade, you can add the matching SainSmart laser module kit to the machine. With this module, it can absolutely give you different ways to unleash your creativity. | What’s Included?1 x Genmitsu 3018-PROVer CNC Router (Some parts need to be assembled) 1 x Offline Control Module 1 x Tools Box (includes emergency stop button, Z probe, etc) 1 x Nut Accessories Box 4 x CNC Clamps 10 x Engraving Bits (1/8†Shank, Cutting Edge Diameter 0.2mm, 20 Degrees) Note: Assembly Instructions and User Guide could be found at the Product Guides and Documents Section. |

Recommended accessories:

| Weight: | 9.8 kg |

| Dimensions: | 46.8 x 41.8 x 26 cm; 9.8 Kilograms |

| Part: | 3018-PROVer |

| Pack Quantity: | 1 |

| Batteries Required: | No |

| Batteries Included: | No |

| Manufacture: | SainSmart |

| Quantity: | 1 |

| Reference: | 3018-PROVer |

The operation and functionality of the machine is really easy to understand. Trying to get the best results is really interesting as there are so many bits and techniques to cutting.

I look forward to diving deeper.

I am a mechanical engineer and this is a very well designed machine. The customer service from sainsmart is also unmatched. They will replace parts under warranty (I have broke several) and answer many programming questions. Easel pro works great with it. KEEP YOUR FILE NAMES SHORT TO AVOID ERRORS

Ich habe mir die Frse gekauft, um kleinere private Projekte zu verwirklichen und den Einstieg in die CNC Bearbeitung zu wagen. Die Verpackung der einzelnen Komponenten war professionell sehr gut und auch der Zusammenbau der Maschine ging fr Laien gut von der Hand. Es ist alles sehr gut Schritt fr Schritt beschrieben. Bei der ersten Inbetriebnahme hatte ich zunchst meine Problemchen, aber ich bin Laie und daher zu vernachlssigen.

Leider fiel nach einem Tag die Steuerung der X-Achse aus und ich kontaktierte zuerst den Support von Amazon, die mich dann an den Support von Tech Maker weiterleiteten. Da mein Englisch nicht das beste ist schrieb ich in Deutsch und schilderte das Problem. Einen Tag spter erhielt ich schon die Antwort und genau 5 Tage nach meinem ersten Kontakt bekam ich ein neues Mainboard per Express Lieferung aus Asien zugeschickt.

Das nenne ich Service, einfach hervorragend.

Die Maschine ist fr Anfnger bestens geeignet und wenn etwas defekt gehen sollte ist der Support von Tech Maker einfach grandios. Kann ich nur weiterempfehlen.

Spedizione impeccabile pacco arrivato nei tempi e dentro imballato molto bene, la macchina si presenta robusta e ben assemblata, le prime prove sono state molto soddisfacenti e con una precisione notevole…

The instructions for the assembly are complete and the video makes it pretty obvious. All of the cables are nicely labelled and a corresponding label is on the circuit/driver board. It takes a few minutes but none of it is all that difficult. Once fully assembled everything worked as expected.

If you are a Mac user, ignore most of the documentation talking about serial drivers; modern MacOS has the serial drivers built in so there is no need to install them. The Candle software itself does not work so go looking open source package UGS or use one of the web based tools.

After experiencing inconsistent results connecting via USB I found if you turn off the 24V power, connect USB to the computer, connect with UGS, and then turn on the 24 V power things work fine. If you turn on the 24 V power first UGS gets stuck “connecting” but never actually transitions to “idle” which is what you should see when properly connected.

If you are interested in doing more than some basic etching work with wood, be prepared to purchase additional bits. The package includes 12 bits suitable for etching and small tasks but are not much use for making pockets or larger carving tasks. Don’t expect to be able to work with metal to make gears and such, the motor is no where near powerful enough and even a small project would take many hours. Etching of metal may work but cutting metal is unlikely to yield acceptable results.

I was somewhat disappointed once the 3040 extension spoil board was installed because it reduces the z-axis; there isn’t room to use the z probe on top of a 3/4″ piece of wood or room to work with a piece of wood 1″ thick. There is room for the 3/4″ wood however, just that it makes setting the z-axis to zero impossible with the probe. Spread a piece of tin-foil on the top and lay the z-probe upside down on the foil. Connect up the alligator clip to the bit as usual and run the zero commands. Not as convenient as the z probe by itself but it will work. If you go looking, there are some youtube videos explaining how to use the old 3018 side rails and some brackets to raise the z-axis and that’s my next to-do so I can handle thicker pieces of wood or work with 3/4″ stock without having difficulty setting the y-axis zero point.

I had a strange problem with the offline controller. It was showing error code 2 all the time. I contacted support, explaining the problem and within a day a new offline controller was on its way. The replacement worked perfectly. I had a few other minor difficulties but their support was great. Very helpful and provided assistance and advice.

Overall this is a solidly built unit perfect for small projects and learning about CNC.

Great little unit, I am using the Mac version of universal Gcode sender. Still testing but I like what I have got so far. This version has Aluminum plates and frame the only acrilic is the side covers. It can be upgraded if you wish with better Z axis aluminum part https://amzn.eu/d/es3Zw8s and exstend the length.I will do this myself later on but for now going to use as is. Negative is the hand controller but you will get use to It. The instructions are ok not perfect there are plenty of people Youtubing the build if you need help.

velocita nella consegna materiali di ottima fattura divertente da assemblare ottima la dotazione a corredo funzina benissimo personalmente l’ho associata ad un laser blu 5,5W e giustamente guide e assi vanno lublificate con grasso teflonato sono pienamente soddisfatto

n.b la uso per lavoro

I have been thinking about getting into CNC for quite a while, but the cost and learning curve always scared me off. Getting into it for under $300 was acceptable. I’m learning a lot, and will soon either upgrade my SainSmart Genmitsu 3018-PROVer or purchase a larger unit. This is a great unit for absolute beginners to learn on, not a great one for those already experienced or for those who want to go into production.

This is a great machine for starting out if you know what to expect. This is a very small machine. Unable to do much more than a nameplate. Customer service is outstanding like other reviews say. I bought the extension pack and when trying to remove the coupler from the lead screw the 2 little set screws stripped. I contacted support not expecting much. They asked me what I needed within 2 days. Then that day responded to every email and sent out a stepper motor, lead screw and new coupler and I had it within a couple days. That’s awesomely quick. So then I expanded it and it was still too small for my needs but I had a great experience. I have already order the 4030 proverxl as it seems to be the best for it’s price range and more of what I need. These prover series are the best!

I never worked with CNC machines and the only reason that I got it was to make toys for my son. Of course, I had my share of frustration with the machine and software! But The first toy that I made was a rabbit and I absolutely love it. My son shows it first to his playmates before any other toy. I had a guest for Christmas and I made them coasters as a gift, which even in their eyes was amazing. I just got a Y extension to make bigger toys. I am not an expert but this machine works well for my purpose.

Fr den Preis gut, einige Verbesserungen waren sehr gut,

1. der not aus ist an einer ungnstigen Position, vorne wre viel besser.

2. die Endabschaltung bei manueller Steuerung muss jedes mal mit lange Enter drcken besttigt werden,

das fhrt bei inigen Programmen zu Fehlermeldungen, die auch dort noch mal besttigt werden

mssen.

eine einfache Abschaltung wre besser.

3. Fr einiges Billiger bekommt man fast die gleiche CNC Frse. Habe mich aber fr diesen Hersteller entschieden.

Trs bonne machine pour dbuter dans la CNC .Par contre ne vous attendez pas a usiner de grosses pices. La livraison super rapide 2 jours avant la date prvus.

Assembly was easy and the directions were clear. Overall I’ve had a lot of fun learning CNC with it. Make no mistake, this is a beginner machine, but it does everything I’ve asked so far. I definitely recommend the 20k spindle and the 3040 extension to go with it.

I agree with all the other reviews regarding the build, it takes quite a while. You should have no issues if you take your time reading the manual paired with the video. I took my time and it took me about 2 hours.

For the first interactions, I simply used the included designs to test and they seemed to work fine. I will say that Candle has a very steep learning curve and I looked for other solutions. Easel worked out great and it has a 30-day free license. The real trick is learning feed rates, plunge rates, pass depth, etc., which comes with testing. A good rule of thumb for pass depth is to divide the width of your cutting bit in half and use that number. If your bit cut’s 1/8″, set your depth pass to 1/16″. Luckily, I have not broken any bits (I bought more aside from the provided ones). I do recommend buying carbide bits, they hold up very well and if used properly they will last. The more you work with it, the more you feel comfortable finding your settings.

Also, do your research on the different types of bits and how they are used. Upcut, Downcut, Combination, Ballnose, V-bit, flat end, etc. Using the bits straight out of the box will leave you disappointed if you want to get something carved in a decent amount of time. Use the finer point bits for detailing and buy a larger bit for cleanout. You will thank yourself!!!

The only thing I don’t like about this machine is the small cutting surface, I kind of knew this coming in but did not think about adjusting size because you need to allow for the hold-down clamps. I will probably buy the Y-axis extension kit to gain a little more surface. Also, the clamps while effective are a pain in the you-know-what to use, so I also purchased the quick clamps for easier clamping & unclamping.

Extras to consider purchasing: Quick clamp hold-downs, Y-axis extension kit, upgraded spindle (20k rpm), dust shoe, carbide bits, and some kind of work light if you don’t have one.

After this experience, I would definitely buy another Sainsmart CNC, only bigger!

Overall this is a great machine for a beginner to learn on, and if you are only doing smaller jobs, it is more than sufficient.

Hatte bisher mit CNC-Frsen noch nie etwas am Hut.

Zusammen mit dem CAD-Programm EASEL konnte ich innerhalb krzster Zeit meine ersten Projekte umsetzen.

Der Aufbau ist relativ einfach, es ist aber kein Fehler wenn man etwas handwerkliche Geschicklichkeit mitbringt. Ansonsten war die Inbetriebnahme problemlos.

Zur Haltbarkeit kann ich noch nichts sagen, denn ich setze die Frse nicht so oft ein.

Tolle kleine CNC fr den Anfang, fr kleine Bastelarbeiten perfekt. Metall oder hnliche harte Materialien wrde ich damit nicht bearbeiten, aber fr Holz und Acrylglas ist es gut geeignet. Mit dem Support habe ich auch gute Erfahrungen gemacht, nach 1.5 Jahren ging der Spindelmotor nicht mehr an, nachdem ich im Betrieb den Hauptschalter ausgeschalten habe. Sofort wurde mir angeboten kostenfrei eine Ersatzplatine zugesendet zu bekommen. Als das Problem dadurch nicht behoben wurde, haben sie mir ebenfalls kostenfrei mehr Teile zugeschickt bis die Maschine wieder funktionierte. Zu erwhnen bleibt, dass sowohl die Anleitung und die Software, als auch der Support komplett auf englisch sind.

Easy to assemble. There are two videos from techydiy that will take you through the process of assembly and setting up the G-Code parameters.

It’s a small machine, so it’s very limited on the size of your projects. I’m getting good results and am very happy with the machine.

I did have an issue with the top z-limit switch. I contacted Sainsmart and, after confirming that it was still under warranty, they shipped out replacements for me. The switches were temporarily out of stock, but the kept following up and I received them about two weeks after first contacting them. I thought that was pretty good service.

The only issue I have with the machine is that the bracket for the spindle is plastic, not metal, and I can see some flex when the cutter first engages with the work piece. I’m not trying to machine anything with tight tolerances, so it’s not really a problem. Just something I noticed.

If you want a CNC router to understand the process and to practice with the software at a very good price, I recommend this machine.

I am Registered Partially sighted & it took me a week from the start to Make the spindle move. Love it/

Comes part set up, Trust me if you have never used G codes it is an eye opener. Will take time for you to grasp it, But once you have well all will be good with the World & you can sell this (doesn’t depreciate much) & get the next size up. not like you would expect the tooling that you should use is expensive. & workspace is not very big but i got it to add Designs to my products. loads of really good videos to watch & you would be better off becoming an Amazon Prime member before you buy this Machine, Get free prime delivery & save a bundle on other purchases too

Watch the videos & check it’s complete before you start Building. Top CNC router for Entry Level. You could even up grade it when you feel you want more Get the next motor size up & a metal Motor mount.

was ein bisschen schade ist ist dass sainsmart beim erhaeltlichen zubehoer weit unter der qualitaet der 3018 bleibt. die fraesspindel mit 20.000rpm ist von rundlauf und vibrationen her unbrauchbar und nicht mit der originalspindel vergleichbar. die fraesersets von sainsmart taugen auch eher wenig und die er11 spannzangen-sets haben teilweise einen absurden rundlauffehler von 0,5-1mm.

also – 3018 fraese top – angebotenes zubehoer flop. (ausgenommen der kleine laser genmitsu 5,5w mit luftduese, 0,1mm*0,1mm der wirklich super ist!)

J’ai achet une CNC Sain Smart 3018 prover et j’ai prouver beaucoup de difficult configurer GRBL pour bien faire fonctionner la machine .Aprs plusieurs changes de Email avec le service a la clientles Sain Smart m’a expdi un nouveau Controller Board sans que jai a leur demander. Je considre que j’ai eu un excellent service de la part de Sain Smart.

Great CNC Mill for the price. You can upgrade it too. The shipping was quick, assembly was easy. I had one micro switch that wouldn’t function properly, but had a replacement on hand and replaced it. I’m very happy with the quick delivery of this item, and will most likely be a repeat customer.

I had this product for a year. I used a lot in the beginning and then put it off as I was busy with other projects. After a while, I came back and worked on this machine and something was not working. I contacted the customer service. After a day, Hong from Sainsmart, provides me a list of diagnosis methods. I tried all of them, did not work and sent him the screenshot. The next day, Hong informed me that he was sending me another control board for free as it was covered in the warranty. He also followed up with me when my new control board came and checked if everything is alright. Excellent customer service.

Also, the machine is super easy to assemble and the limit switch on the x,y, and z axis make it very safe. The spindle is pretty powerful and can do some damage and it can also cut some thin aluminum. (You need to go very slow).

The one thing that this machine can improve on is the instruction on the programming side. As a beginner, I spent a lot of time and installed several programs (including freeCad) to start to cut my piece.

At the end, I found the easiest way is to create a simple text file and type the G-Code myself. If there is simple instructions/examples on G-Code like G0, G1 and G2, it will make a big difference to get a beginner started. As beginner, I just want to cut a straight line to test it out, but I found that it was a lot of learning and time using freeCAD other CAD program to do such a simple thing.

My First CNC machine. It seems very well built and went together easily. A few of the pre assembled parts had loose screws which were easy to fix. Still a learning curve with software choices etc. Probably can’t say which software here. But the one that’s commonly recommended works well. Learned a lot from on line forums in regard to setting up and first cuts. I had purchased a selection of bits and cutters at time of purchase. So no delays in trying things. I also upgraded to the 20000 RPM spindle from day one. Seems smooth and not too noisy, although first use was only at 12000 RPM. Looking forward to more projects.

I was concerned after reading some negative reviews but when I unpacked it, everything was there and in good condition. My son and I assembled this in about 1 hour. The instructions are very clear. We were impressed by the engineering of the unit and the obvious thought that went into assembling it. After connecting all of the wires, we turned it on and everything worked properly. We connected it to a computer and, after installing the device driver and choosing the proper communication port (that’s important) we were able to run one of the test files included and that worked perfectly. The process might be difficult for a novice, but if you can follow instructions and watch the videos, it’s not too difficult. The only thing we were not prepared for and couldn’t immediately do was set the height of the Z probe because we didn’t have proper calipers on hand. I imagine you could take it into any hardware store and get a measurement if you don’t own calipers.

This CNC is totally worth it if you want to get into this hobby/side gig. I thought about getting this one for the longest time (a little over a year) and I have to admit it is addictive using this machine. I am a Mac user, so a lot of stuff is geared towards Windows. I did a lot of research, and found that using easel, and dragging and dropping the g-code into the SD card provided makes life a breeze when using the offline controller. YouTube is a big help as well, and a majority of reviews talk good things about this machine. I had my doubts at first, but man is this thing awesome

Aprs plusieurs mois d’utilisation, je suis trs content de cette machine. Je prcise que j’en ai une utilisation assez simple de gravure ou de petites dcoupes. J’apprcie de pouvoir travailler le fichier tranquillement sur mon ordinateur et de le transfrer ensuite sur carte SD (la machine est loigne de l’ordinateur) et d’avoir les commandes de contrle indpendantes pour calibrer, faire le zro et lancer le fichier. Un fichier bien prpar et le rsultat de qualit est au rendez-vous

Mi piacerebbe condividere la mia esperienza con questa cnc, premetto che non sono un novello ne un esperto. Ho comprato questa cnc guardando le recensioni, arrivata in 2 giorni, la monto la installo e cerco di farla partire, ma nulla da fare si muove di un centimetro e poi va in blocco e cosi sempre. Ora anziche rimandarla indietro decido di contattare l’assistenza clienti dal sito della Sainsmart e chiedere spiegazioni, qui arriva la parte bella, ho trovato persone molto competenti e gentilissime, mi hanno fatto fare delle prove, mi hanno chiesto di inviare video del problema, e alla fine hanno capito che il problema era la scheda di controllo difettata.

Immediatamente quindi dopo 3 ore mi arrivato il track della spedizione della scheda nuova e in meno di 8 giorni e arrivata,l’ho montata e tutto funziona perfettamente

ci tenevo a raccontare questa esperienza perche molte aziende a volte neanche rispondono oppure ti dicono restituisci e risolto, perch per me questo significa che loro ci tengono ai loro prodotti e anche ai clienti

Complimenti quindi alla Sainsmart e a tutti i loro collaboratori

Grazie

Produit fonctionne bien avec les fichiers fournis. Attention, la multitude de logiciels pour la conception de pices 3D et leurs transfert en format GCODE sont payants.

I really enjoy this machine and all it can do.

Although I did have issues with the control board, the help and stand by their product support was outstanding! Worked with Marcia, and nothing but praise on how I was treated, and the outcome. You do have to understand that the communication is time consuming because of the time differences. I am not a patient person by nature, but the help made it easier.

Setting up the machine took about 2 hours. I watched the video that shows the instructions on how to build and that made it fairly easy. I had a couple issues with the Z Probe not working correctly and I contacted costumer support. It took a few days of back and forth to talk with tech support. They ended up sending some new parts for free. Everything works well now. Overall, it is a good machine but there will be a learning curve if not used to this type of software.

As a beginer to cnc this Prover works great for me. I had an issue with the usb port becoming loose after a week and sent an e-mail to sanismart regarding the issue. I had a respone the same day and a new board three days latter. Their communication and responses with any questions or issues is one of the best which I have incountered. For the price I feel that this is an excellent machine,quality parts and safety features.

John F.

I probably didn’t do enough research before purchasing but saw SainSmart’s name come up in searches a lot and Amazon reviews showed they had good support. Turns out I did get lucky as they and their Facebook page are one of the best resources for these 3018 machines.

As happens sometimes, I had a bad part but their email support helped me trouble shoot and shipped a replacement part all in less then a weeks time.

Compared to their own older 3018 pro, this newer model comes a bit more pre-assembled and likely more square then it would have been if left to me. This Prover also appears to use less plastic and so should be stiffer. If your comparing only on price, make sure you account for the better quality parts.

My goal was to use it to make a pinewood derby car. Their 1.5 inch height is really the upper limit of a project for this machine but I was successful. Since most bit lengths will be around 1/2 inch you’ll also be limited on your 3d shapes possible though. Both height and bit length issues exist for all machines in this class and not unique to this one and this model has one of the higher z limits.

The frame parts are good quality but it is let down by the electronics. The controller is a pain in the … to use, much better off connecting it to a pc and controlling it that way. The power supply quality is poor, was having projects freeze up continuously. After days worth of troubleshooting figured out the issue was the power supply. After some research it seems to be a common issue with poor or inadequate.

Edit. The seller made contact with me with regards to the power supply issue. There was an Initial batch that had problematic power supply’s. They have since fully refunded me for the power supply I purchased to rectify the issues I was having. The customer service from seller is great and appreciate the honesty from them. I therefore added another star to my review 🙂

I purchased the SainSmart Genmitsu 3018 PROVer to create signs and custom plaques. It works fine for this, but the small work area limits the machine. I upgraded to the 4030 extension kit and resolved this limitation. I started having an issue with power supply cutting out causing the spindle to turn off and on while engraving soft pine which causes the engraving bit to break and the wood to chip badly. I contacted tech support and Marcia responded quickly and sent me a new power supply. This resolved the issue. Very happy with the contacts I have had with tech support.

I recently got the machine for woodworking purpose. It works pretty well on hardwood, although you need to do some experiments to find suitale bits for your purpose. It comes with a software package and apart from manual control you can manually move the machine with the software without Gcode. The manual controller is very useful and you can use it for precision drilling purposes which gives a precision of 0.1 mm for all the axis. One I got my order the manual controller was faulty, however they have great customer service and sent me a new one which was fine.

For the money this is a very capable machine unfortunately the control board on mine failed, I emailed the seller who got back to me very quickly and after telling them what I had done to ascertain that the control board had failed and that the machine was in warranty they arranged for a new board to be sent to me.

When it arrived it was duly installed and my machine was back up and running again so full marks to Tech Maker.

The machine kit builds OK. Web videos are much better than the manual for assembly because you see it at angles. Lots of small parts but accurate in pre-drilled holes etc. The operation is not for beginners even though the machine is aimed at beginners. The attached controller is not intuitive at all and hard to use at best. When it works it does work. Get Dremel etc routing bits (you will need to cut it down in length.) The supplied bits are more for engraving than anything else, like cutting plastic, wood etc. The machine is solid. The software like Easel is odd to use, and Candle works but is also odd. An “end” stop error requires a reset which itself requires a sequence of frustrating button presses. The optional waste boards work but the hold down clamps are not usable to their full degree. It is fascinating overall, so I would recommend it, but go in expecting some setbacks.