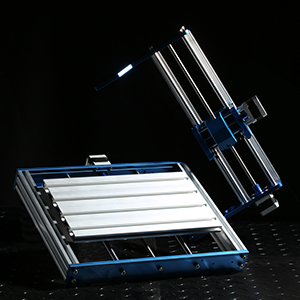

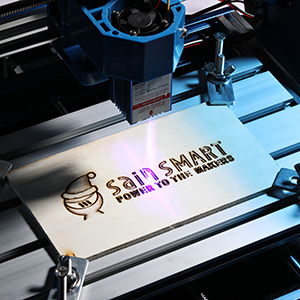

SainSmart Genmitsu 3018-PROVer CNC Router Machine with GRBL Offline Control, Limit Switches & Emergency-Stop, XYZ Working Area 300 x 180 x 45mm

SainSmart Genmitsu 3018-PROVer is the successor to the 3018-PRO, and the new version has brought improvements to many parts, including the excellent design and safety features, pre-assembly, upgraded mainboard, etc. Whether you’re a CNC beginner, a hobbyist or a small business owner looking for an enterprise-quality for commercial purposes, this is an excellent choice.

SPECIFICATION:

| Effective Engraving Area | 260 x 155 x 35mm(10.2 x 6.1 x 1.4”) |

| Frame Size | 400 x 330 x 240mm(15.7 x 13.0 x 9.4â€) |

| Frame Material | Aluminum |

| Z-Axis Component Material | ABS |

| Spindle | 775 motor, 12V~24V, 10000 RPM |

| Rated power | 60W |

| Maximum power | 120W |

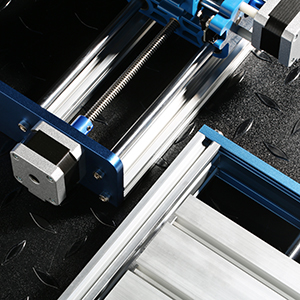

| Step Motor | 1.3 A, 12V, 0.25 Nm torque (2.2 in-lb) |

| Drill Bits | Tip 0.1 mm, 20 degrees, Diameter 3.175 mm |

| Supported OS | Windows XP, Windows 7 32/64 bits, Windows 8, Windows 10, Linux, MAC OS |

| Software | Grbl control(Candle) |

| Power Supply | 24V/4A |

| Great for | Hobbyists, Crafters, Woodworkers, Industrial Designers, Educators, Engineers, Jewelers and more! |

| | | |

|---|---|---|

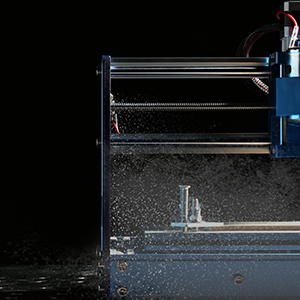

Efficient Pre-assemblyThe 3018-PROVer is the newest addition to the Genmitsu CNC 3018 series family. This pre-assembled desktop CNC machine allows you to be up and running in 15 minutes instead of 2 hours, making it no challenge for beginners. | High QualityBoasts an all-aluminum body with an oxide blue look, the 3018 PROVer gives you a premium look and feel for your machine. | Safety DesignThe 5mm acrylic baffles can block the ‘flying’ pieces of wood/other cutaway materials so that you can safely monitor the engraving process. |

| | | |

|---|---|---|

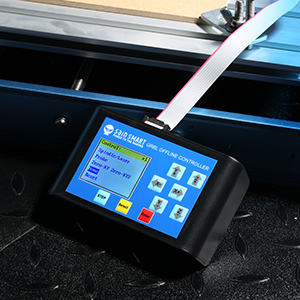

Offline Controller with 1.8″ TFT LCD DisplayThis machine comes standard with a newly designed offline controller with 1.8″ display so you can view readouts clearly and control the CNC router without connecting to a computer. | Laser Module AvailableIf you are an experienced CNC engraving enthusiast looking for an upgrade, you can add the matching SainSmart laser module kit to the machine. With this module, it can absolutely give you different ways to unleash your creativity. | What’s Included?1 x Genmitsu 3018-PROVer CNC Router (Some parts need to be assembled) 1 x Offline Control Module 1 x Tools Box (includes emergency stop button, Z probe, etc) 1 x Nut Accessories Box 4 x CNC Clamps 10 x Engraving Bits (1/8†Shank, Cutting Edge Diameter 0.2mm, 20 Degrees) Note: Assembly Instructions and User Guide could be found at the Product Guides and Documents Section. |

Recommended accessories:

| Weight: | 9.8 kg |

| Dimensions: | 46.8 x 41.8 x 26 cm; 9.8 Kilograms |

| Part: | 3018-PROVer |

| Pack Quantity: | 1 |

| Batteries Required: | No |

| Batteries Included: | No |

| Manufacture: | SainSmart |

| Quantity: | 1 |

| Reference: | 3018-PROVer |

J’ai eu un problme de configuration aprs l’utilisation du laser car je n’arrivais plus graver avec la machine en utilisant le contrleur offline et celui-ci induisait un comportement anormal de celle-ci. J’ai pris contact avec le support technique de Sainsmart pour leur exposer le problme. J’ai eu tout de suite contact avec Marcia du support technique qui fut une interlocutrice l’coute de mon problme de contrleur et aprs essais nous n’arrivions pas une solution. Elle m’a fait parvenir rapidement en moins d’une semaine un nouveau contrleur offline, mais le problme n’a pas disparu pour autant, donc de nouveaux changes avec Marcia et puis finalement elle a trouv la solution qui est de restaurer $32=0 aprs chaque utilisation du laser, pour lequel $32=1, pour pouvoir graver avec le contrleur offline. Si on utilise le PC ou le Mac le problme ne se pose pas.

Je remercie infiniment Marcia pour le suivi et la recherche de solution mon problme ainsi que sa ractivit aux nombreux mails que nous avions ensemble.

This is the first CNC machine I have used so I didn’t know what to expect.

The macine assembly went well, instructions were execellent and in a couple of hours it was together.

1.) Testing showed the y axis moving in the wrong direction. I found two wires in the connector for the y stepper motor were crossed. I have later discoverd I could have fix this in the configuration file.

2.) Homing was not working. After a great deal of searching, time watching ytube videos and playing with the configuration file, I have it working. Setting $5=0 in the configuration got it fixed. I would have been nice to have exapmles somewhere of working configuration files.

It has taken a year, working on it until frustrated then going back again at a later date to get it to where I can actually use it. I ‘m happy with some sample cuts that it has made and I looking forward to making several projects to really test it.

I use this machine in my RC Plane crafts and had never used one before. The software that you use is key. There is software for every use, some very expensive and some free but plan on hours of getting educated if you go cheep. Excellent machine and does more than expected.

I went to level it, expecting to need to do a leveling with a router bit on my spoiler board, and it was already level on initial assembly. I did not need to do a special leveling. Maybe I was lucky, but it shows that manufacturing tolerances at SainSmart are fairly tight.

One last thing – Don’t forget that you’ll need a USB cable long enough to reach the PC.

I had a problem during assembly (that I unwittingly caused). I contacted support via email and received a timely reply. That’s a huge plus for buying this.

If you don’t realize it yet, buying this inexpensive unit will make you want more of this world, and you’ll probably be looking to upgrade the size and power of the router. You will learn a lot doing so, and I’d encourage you to buy the rail length upgrade. It’s easy to implement and doing so will give you the confidence to expand it further. You’ll realize that the software will work with just about any size X, Y and Z you come up with.

J’aime bien le produit pour graver le bois. Le branchement d’un ordinateur est trs complexe, ce n’est pas du genre plug and play du tout. Le fournisseur devrait travailler sur ce point que je considre insatisfaisa

I have never worked with wood and someone gifted me a wood router recently. I used it to add professional looking edges to my laser etched projects. I enjoyed the step up in quality so much that I thought I could step up my new skills game to a small CNC machine.

I bought the 3018 Prover and quite a few accessories. While there certainly is a learning curve there are excellent forums and user groups out there for help. I went from being giddy at carving the word “Test” into a piece of wood to making more elaborate things like signs and trays in the matter of a few days.

Build quality is excellent. Instructions were good. There are good build videos out there as well. The machine is well made and works as advertised. The hardest choice you will have to make with your software selection. Easel (recommended by Sainsmart for Mac users) is a great way to get started but it should be known that it is web based software. I could NOT get Easel to connect to my machine though as I was running a local DNS server. Once I changed my DNS settings on my computer from the local server to Google (8.8.8.8) then it connected. This was disappointing to me however this can’t detract from my opinion of the machine itself.

Anyway, Easel is pretty intuitive and a good way to start. You’ll probably find that you’ll move on quickly.

If I had anything negative to say about the Sainsmart 3018 Prover it would be that it will wet your appetite for a bigger and larger machine quickly but for small, quick jobs it is an excellent little CNC.

The blue plastic panels on the side are always in my way it seems. They are easily removed and replaced and a good idea to have them on for additional safety.

If you are like me, with no previous CNC or woodworking skills this purchase is a no-brainer even if you intend to buy a full sized CNC in the future. Learn and make all your mistakes on the smaller, cheaper machine.

Also, because of the giant mess CNC’s make, my big machine is in the back yard shed. I bought an enclosure for the 3018 Prover and can cut inside and contain the mess when it is too cold or nasty to be out in the shed. Even if you have a large CNC machine having the Sainsmart 3018 Prover is still nice.

I have never owned or operated a CNC router before or even seen one in operation. I bought this to learn how they work and hopefully make some PCBs (small ones). This machine has all I needed to begin etching planar surfaces, including milling PCBs. I first tried to cut some MDF wood and found myself making little circular pine Christmas tree ornaments for all of my family members, setting the PCB project aside by the end of the second day. All of the software needed to CADCAM PCBs and the wood ornaments can be found for free. I settled on Fusion 360 (personal hobbyist license – free), which works well for the wood ornaments and designing the PCBs. I found, after a few attempts, that Candle / GRBLControl (also free) works better for milling the PCBs as it has a height mapping feature. I can’t say enough how much fun I have had this past week learning the ins and outs of the software and manufacturing process. I’ve already ordered the motor upgrade, laser upgrade, and a few sets of milling bits just based on the quality and value of everything I’ve encountered related to this machine and Sainsmart. This will probably be the first and last CNC machine I buy simply because it does everything I could ever imagine doing with one. It may not have the power of production-level machines used in the industry, but it is accurate down to sub-millimeters. I was able to pocket a holder for PCBs of 102x79mm and it did exactly that, without any calibration of the router after I had assembled it. There is a steep learning curve at first, mostly related to the many options of software and parameters related to manufacturing parts. But, if you have used CAD programs before and are familiar with the design process you will pick it up quickly. Looking forward to the 3040 upgrade kit getting back in stock – although I read that there may be problems with compatibility of the laser module, due to the MDF+aluminum bed combo putting it outside of a usable height.

Der Zusammenbau ist einfach, es ist empfehlenswert bei den vorgefertigten Teilen die Schrauben auch nachzuziehen wenn man wei worauf man achten muss, die Steuerung ist GRBL mit PWM und kann auch mit ESTLCAM benutzt werden, fr diesen Preis eine Gute brauchbare Frse

When I opened the box this came in, I was very excited to piece it together and start making some things. However, after I put it together I tried to turn it on and make it cut a piece, but it wouldn’t work. It would cut for a few seconds, then quit and say it was finished with the cut. I figured that the problem was me, so I didn’t give this much thought. After a long time of never finding out what the problem was, I finally took it to my teacher, who knew more about these machines than I did. We took the machine apart and looked over every piece to try to find out what the issue was. Eventually, we found it. We couldn’t fix the problem, so I decided to contact customer service. I sent them an email detailing what was wrong with the machine. Within twelve hours, they contacted me back and told me that they were sending a replacement part immediately, and that I would get a confirmation email. Two days later the part came. I put it on the machine, turned it on and it worked flawlessly. I have had no more problems with this machine and I am EXTREMELY happy with the help that the Customer Service provided me. I highly recommend this machine and its company. They worked hard to solve the issue I had. I am very happy with the help they provided for me.

This is a great machine if you’re just starting out, which I was, I found the easel software to be very user friendly and very easy to use, cost like 20$ a month but I say we’ll worth it, I would highly recommend getting the extended Y axis table and spoil board, opens up more opportunity and a little more freedom due to less size restrictions, either way I wouldn’t try and run it to its limits! It does cut very accurately, though it does take quite a bit of time, I haven’t tried hardwoods yet but with the upgraded spindle I haven’t had any issues in soft woods, plastics and aluminum, if you do aluminum don’t be cheap on your bits, and don’t get greedy and set your depth to deep per pass. It’s a little, fairly noisy, but if you’re crafty a rubber maid tote, some sheet foam and a cord grip pretty much cuts the noise, the controller is a little tricky, so just make sure you play around try some simple copy and paste projects (you can do that on easel I’m not sure about other softwares) not so much detail to get the hang of things. Awesome little machine, great for learning or deciding you’re actually into it before you upgrade and very fun to watch!

Easy to assemble, my tip would be to take some calipers ($20 pair is fine, you can use your Mitutoyo’s if you want.) and measure the gap between the gantry and the rear of the machine, lightly tighten the screws and nudge each side until they’re equal and you’ll end up with a very square machine.

The spindle runout was ~.0005″ which is great considering the housing is plastic.

Backlash is is also in the low ten-thousandths.

I started with some simple engraving and thought it was nice.

So I moved onto slotting and pocketing some simple coaster pieces.

That was also great once I got my fixturing printed. (Missing islands on the snowflake is a plyboard issue, not a machine issue.)

My real test was 3d contouring/simultaneous 3-axis moves (The death of a backlash-y machine).

And those turned out amazing, even with one in MDF.

You can feel the grip and see the slide grooves on a 2″ long 1911 and that’s pretty amazing.

Like resin 3d printer amazing.

As an CNC machinist I love this little guy already and will keep it very busy.

This machine is my first foray into CNC machining and so far this machine has worked very effectively.

Being an electrical engineer and software developer did not hurt while learning to use this device. I will admit that it was still a challenge to get all the dots to line up, (i.e. there are a lot of factors to consider when choosing software tools, bits, feed rates, etc.). This required a lot of determination and focus for an old guy like me. But if I can do it you can too. Just don’t expect it to be a piece of cake and give up prematurely.

Having said that, the machine itself has performed very well. The accuracy is good and I like that it is self contained and compact for the kind of stuff I do. Aside from a small problem with the emergency stop button sticking, everything has worked well.

I recently purchased their dust collection shoe that has an excellent design and is reasonable priced. I had a minor issue with it, (that was largely self inflicted), and they were extremely helpful and immediately sent me a replacement.

All in all I love the machine and I am pleased with SainSmart support as well.

I was surprised by the quality of the unit for the price paid. Yeah it’s small and not perfect but for around $350 or whatever, I was expecting something that felt like it would break it a few months but this feels like it will last at least a year or two without any major issues(I could be wrong on this, only had it for about three months).

Assembly wasn’t difficult however more tweaking and hard to do adjustments are needed to get the gantry properly level to the bed. I wish it had some sort of fine adjustment screws or something to assist with this. The wiring was easy enough. I mostly use mine for engraving plastics and it works well enough for that.

The plastic holder for the spindle works but I’ll be upgrading mine before too long.

I taught myself CAD(YouTube videos) and such before getting this and did not find the controls for this machine to be difficult to learn.

Every once in a while I do notice that it seems to maybe skip a few steps and my engraving is a little odd(same code ran multiple times on identical stock and occasionally it looks different).

Don’t buy this thinking you will be able to machine metal well. It’s not for that. But it works great for me.

J’ai utilis une fraise cylindrique D 3mm venant d’une petite perceuse Dremel

J’ai utilis le logiciel Fusion360 pour crer l’objet 3D et pour gnrer le fichier Gcode

Le pilotage de la machine tant ensuite effectu avec le logiciel Candle (qui fonctionne trs bien) soit via un PC online ou directement par le module offline et la carte SD

This unit is perfect for what I use it for, which is inlay (both male and female cuts), lettering (using single-line fonts designed for engraving), making templates in masonite and plastic, and precision cutting in hard woods. I do my designs with FreeCAD under Ubuntu so for me the offline controller is a must. (If you aren’t familiar with FreeCAD, it is a multi-platform, powerful 2.5-axis CAD program but with a steep learning curve.) I have hit all the limit switches so for me those are also a must. There are a few nits:

-The unit ships with eight engraving bits. I think a far better choice for most people (including me) would be one of the other Genmitsu combination sets at about the same price. Engraving is what I do the least of. Plan on buying bits. Lots of bits.

– As others have noted, the design of the limit switches significantly reduces the travel in all three axes. I need the full X-axis travel for one of my projects, and it is straightforward to modify the motor bracket to gain most of that back. The Z-axis is just as easy to modify, but I haven’t needed to do so yet. The Y-axis is more involved. I have to wonder why the motor bracket was designed the way it is instead of with the simple mods that allow the full travel to be used.

– This isn’t really a nit, but a comment on what to be expected at this price. It is perfectly possible to cut Al alloys using about 0.1 mm passes. Any more than that and the inherent flexibility in the machine will make it hard to achieve clean results. The support rods (only 1 cm diameter) have enough flex that if you push lightly on the corner of the spoilboard it will bend at least 1 mm. So if you intend to cut Al, plan on taking tiny cuts and milling for hours (and using cutting oil; people don’t seem to mention this), or buy a bigger, beefier, “real” mill, for a lot more money. My small, real (but non-CNC) mill weighs around 500 lb., and you just can’t expect something like this to have the same accuracy or capabilities.

So don’t try to push it past its capabilities, and I think you will like it.

Purchased this here on Amazon because of the price and free shipping. I had previously researched this tool on youtube so I knew what I was getting. This is my first experience with these small machines. My original machine had a defective control board, but I had an EXCELLENT service from Sainsmart. They replied to my email within a few hours and sent me a free replacement board.

This is a hobby tool, very entry level. It will give a new user a good learning experience but don’t expect too much out of a $500 machine. Fortunately, it can be easily upgraded to a stronger and larger machine for a very reasonable cost. If you are looking for a hobby tool that will engrave wood, cut styrene or very thin metals, this is a good starting point. Personally, I should have spent a little more and purchased the larger model, but that is only because of my needs, not because of the tool.

Hatte am Anfang Probleme mit dem Mainboard. Den Support angeschrieben und das Problem erklrt. Erst wurde versucht ein bedienfehler auszuschlieen. Nach dem dies ausgeschlossen war wurde mir innerhalb von 4 Tagen ein neues Board zugeschickt. Jetzt tut die frse was sie soll.

Mit das wichtigste ist nun mal der Service. Klappt er nicht sendet man das Produkt besser zurck.

Hier hat alles perfekt funktioniert.

I’m coming from a 3d printing background but this was my first CNC. My impressions of the unit is that it does a good job on light materials. I’ve even milled some carbon fiber plate with it. I tried milling some aluminum and mostly just made a mess but they don’t really advertise it as being able to do this anyway. The reason is partly because you really need to set up a mister to cool the cutter, and partly because the little spindle motor is just not up to par. The unit also uses tubular linear rails for the xy axis and they are a bit undersized in my opinion because the milling head can easily flex causing inaccuracies and chatter. Aside from this, I think the build of the little machine is quite durable. They offer spindle upgrades to this as well for pretty cheap. I think it’s a great starter machine especially for the price. Just like anything else you could always make upgrades to the items I mentioned.

This engraver provides a good product for the value. Assembly was pretty easy, with one tricky step. There was a previous review that stated that the included manual was not helpful. I found that far from the truth, the manual has clear directions with large, detailed full color pictures of every step.

The framework is solid and the precision is excellent. After adjustment, I was able to easily engrave lettering less than 5 mm tall.

The only downside I would mention is that the work hold-down clamps that are included are not a great design. They are limited to a narrow range of work thickness and they are not easily adjusted. But that’s a small point and easily fixed with aftermarket clamps.

I was skeptical at first because of some reviews, but it actually works! And it works really well. I’m having some issues with the homing of the machine, but I think I know what the issue is. Either way, it’s well worth the money.

It works very well, controls are easy. assembling is easy, instructions are good. Quite happy with it. You definitely need a quality cutters, don’t rely on these that come with it.

Acquistata durante i Prime days, sebbene l’abbia pagata molto meno vale anche il prezzo pieno. Completamente in alluminio si presenta bella robusta, arriva parzialmente premontata, il montaggio durato circa un ora per me che sono un principiante delle CNC, il manuale solo in inglese e tedesco ma le foto aiutano molto. Utilissimi gli accessori forniti come il controller remoto ed il probe per settare l’altezza zero dell’utensile. Il sito del produttore fornisce informazioni utili a chiarire tutti i vostri dubbi e l’assistenza veloce e cortese. In meno di un ora e mezza avrete tra le mani la vostra prima fresatura. Gli interruttori di inizio e fine corsa evitano il sovraccarico dei motori ed il pulsante d’emergenza blocca tutto in caso qualcosa vada storto. Un altro fattore a favore la sua espansibilit, acquistando il kit possibile trasformare la 3018 in 3040. Acquisto consigliato a principianti ma anche ad hobbysty avanzati.

As I am writing this it is cutting a tough steel face plate for an electronics enclosure I am typing this.

You just need a good milling bit, and it is going to take along time.

You need to go really slow and go with very small slices, but it will eventually do it.

Repeatability on coordanants is actually not bad for a simple cnc.

Der Aufbau der Frse ist fr einen technisch nicht ganz unversierten recht schnell erledigt, im Prinzip ist alles sehr gut erklrt und alle Kabel auch gut beschriftet und zudem gibt es sehr viele Anleitungen im Internet die man nutzen kann (ich habe etwa 45min fr den Zusammenbau bentigt ).

Da ich die Frse ausschlielich fr Leiterplatten nutze, habe mir gleich die Leistungsstrkere Spindel mitbestellt denn fr derart kleine Strukturen gilt, je hher die Drehzahl desto besser. Wie einige schon beschrieben haben ist dieser Motor dann doch recht laut, aber ich denke das ist bei 20.000U kaum zu verhindern. Um den Lrm zu mindern kann man z.B auch das zus. angebotene Gehuse nutzen (bring etwas aber nicht viel da die Frequenzen recht hoch sind…) oder halt selbst etwas basteln.

Alles in allem eine sehr gute, preisgnstige Frse die sich nicht vor den wesentlich teureren Frsen verstecken muss.

I have owned this for a while now and it is in use virtually every day. I really like using it – both as a CNC router and with the optional laser attachment. It is easy to assemble and get started with it. There is some free software provided and there are many guides available on the internet – including a dedicated FaceBook page. The size of the projects you can tackle is constrained by the size of the machine but otherwise your imagination is the only other constraint.

Great product comes well packaged and the instructions are very well presented, great little machine for the price.

http://s3.amazonaws.com/s3.image.smart/download/101-60-280PRO/3018-PRO-User_Manual-JP.pdfURL

XYZSDURL

PC

D

Die CNC kam gut verpackt und innerhalb der angegebenen Zeit an.

Die Qualitt der einzelnen Bauteile machten einen sehr guten Eindruck. Alle Kleinteile befanden sich in einer Plastikbox in separaten Fchern. Die Fcher mit ihrem Inhalt waren auf einem Beilageblatt genau beschrieben. Alle Verbindungskabel hatten eine entsprechende Adresskennzeichnung was die sptere Verdrahtung recht einfach machte.

Die gesamte Montage gestaltete sich wegen der ausfhrlichen, gut bebilderten Bedienungsanleitung problemlos.

Die Inbetriebnahme funktionierte ebenfalls tadellos.

Ich kann diese kleine CNC Frse, auch fr Einsteiger sehr empfehlen – es macht wirklich Spa.

3018 CNC machines are an introduction to CNC tools , they are very affordable and within their limits very capable. Getting good results with CNC requires learning to use several software tools in addition to the mechanical device – create good designs and this device will execute them reliably.

This PROVer model adds worthwhile upgrades to the basic model, and Sainsmart customer service is excellent and sets them apart from other manufacturers – they helped me quickly and effectively.

The assembly required is well documented, and the accessories organised in subdivided box so all are easy to identify. Everything essential is supplied, but like 3D printers there is scope to add further parts to optimise the device to individuals use.

My immediate need was for a laser cutter but I have found the engraving and milling capability useful and I am working on projects that combine milling and engraving withthe spindle and etching and cutting with the laser.

Recently I had a concern with my 3018-PR0Ver spindle motor. At the request of Hong at Sainsmart, I forwarded a video of my spindle motor operating and they determined it was failing and supplied a replacement spindle under warranty. I was very impressed with Sainsmart’s support and service, Hong was excellent to deal with. When I upgrade it will be a Sainsmart.

Fantastic entry level CNC machine capable of much more then a basic machine. Will grow into your needs as your skill increases

I purchased the 3018 PROVer last fall and it has met all my expectations. I also purchased the laser kit to go with it. Everything worked great until last week when I started having issues with the laser. I contacted Hong at Sainsmart and he immediately replaced it with a new unit. His communication and speed in sending the replacement has been phenomenal!! I will definitely buy from Sainsmart again and refer them to all of my friends. Thanks Hong

Mann sollte beachten, das die Frse nicht so schnell ist wie eine 3000,. Euro Machine, welche 3mm Zustellungen ohne Probleme mit macht. Hlt man sich an kleine Schnitttiefen, ist die Maschine perfekt. Ich habe Plexiglasschilder, Holzschilder, und Frsteile aus CFK beshichtetem Sperrholz gemacht. Wie gesagt, wenig Tiefe, und langsam Frsen sind hier das A und O.

I bought also the enclosure Genmitsu Acrylic CNC Enclosure – Enhanced Protection, Dustproof, Noise Reduction, the laser unit (not yet tried) and a few bits.

Putting it together was quite straight forward with the help of the manual. There are also quite a few videos on the web explaining the process.

The tricky bit is to work with it, as little errors will upset the process. The worst so far is that I broke a bit as the speed of the spindle wasn’t quite right. The machine is not intelligent, so if you give the wrong instructions, it will do the wrong actions…

Support of SainSmart is brilliant, quick, helpful and patient. There is also a user group – although it is on Facebook 🙁 – and loads of good material available on the web.

I’ve ‘designed’ my first item (a box) on fusion 360 and now up to a more sophisticated model…

his is a great little cnc. I’m using it for milling out pcbs

Great tools saved me a lot of time for carvingstill learning how to better control this machine.

Quality product, packaged extremely well, simple, fun assembly, great price, super fast shipping, a buyers dream. Beyond satisfied.

well built,fast delivery,easy to use ,top class machine

Die Komponenten sind gut aufeinander abgestimmt und wer spter die Frse optimieren mchte, kann beim Hersteller passende Komponenten nachbestellen.

Im Zubehrprogramm sind z.B.:

– schnellerer 20.000 rpm Motor

– Spindelhalterung aus Metall (die mitgelieferte ist aus Kunststoff und der schwchste Teil der Konstruktion)

– Erweiterung des Frsbetts

Wer sich whrend des Betriebs im selben Raum aufhalten mchte ist brigens gut beraten, die separat erhltliche Schallschutzhaube dazuzubestellen. Sie mindert den Lrm erstaunlich effektiv und verhindert gleichzeitig herumfliegenden Staub und Spne.

Software:

Alternativ zum Offline-Controller ist auch “Candle” als PC-Steuersoftware fr die Frse dabei.

Fr die Konstruktion eines 2D/3D Modells und die Programmierung der Frse (CAD/CAM) muss man sich selbst um eine Lsung umschauen.

Meine Emfehlung:

– Tinkercad als CAD-Software (gratis, webbasiert) oder Inkscape fr reine 2D Konstruktionen (free, Windows, Mac, Linux)

– Estlcam als CAM-Software und optional auch als CNC-Steuerung (Windows, 50 EUR)

In fact, the only issues that any of my cuts have had were of my own making. The machine works very well. That said, prepare to do some learning, some troubleshooting, and some problem solving. This is my first CNC, but I have extensive experience with 3D printers, and they’re the same way. This machine isn’t there to hold your hand while carving out intricate masterpieces. It’s a tool that you need to learn to use.

Another reviewer said something like “8 hours of failure was too much.” (I had the same problem that he did. It was solved by changing the “Safe Retracts” setting in Fusion360.) If 8 hours of failure is too much for you, then this isn’t the machine you want. To make this (or really any CNC machine) “work”, you will need some basic understanding of G Code, 3D modelling, woodworking, and electronics. You don’t need to be a master at any of this stuff, but you’re going to touch all of it. It will take time. You will screw things up. You will get sawdust in your hair. That’s what makes these things fun.

Now, more specific to this machine itself, I was very, very impressed. There are many very similar units on Amazon, and I selected this one because of the included upgrades, and the known brand name. I found the machine to be extremely well built, and straightforward to assemble. The inclusion of limit switches is important. While limit switches can be a bit frustrating, they are there to make sure you don’t accidentally send the machine a command that will damage it, and the work perfectly for that. I find the offline controller to be wonderful. There seems to be a lot of hate for this part, but I like that I can run he machine “headless” and not have to leave a laptop in my dust shop. I actually had a much smoother experience using the offline controller than I did using the PC-based Candle, but they both do the same job. My motor doesn’t wobble, isn’t loud, and hasn’t had any issue cutting through various woods at 300mm/min. I did several calibration tests on the machine as soon as I got it built, and didn’t have to adjust anything.

The only bad things about the machine are the hold-down clamps that are included (they work, but are the definition of “fiddly”), the included Vee bits (again, they work as they should, but why give me a bunch of Vee bits and no end mill?) and the size of the workspace. The 3018 is actually a great size for a small workspace like mine, where it will need to be moved and worked around, but just like everyone else, I’d love to be able to make bigger stuff.

I’ve probably said enough glowing stuff about this device, but I’ll sum it up, here. When I spend ~$350 on a piece of Chinese technology that’s based on open source designs, I expect to get a pretty low-end product that I can usually upgrade to make it useful. In this case, I got a solid, well-deigned, functioning piece of gear. I haven’t been this amazed at how well a cheap gadget works since the Elegoo Mars Pro.

If you’re looking for a cool tool with a steep, but fun learning curve, look no further. If you want to easily and quickly cut wood (or metal) parts with the push of a button, maybe wait a few years.

Software That I Used:

-Candle (included) for machine control

-Easel (very limited free use) for design and GCode Creation

-F Engrave (free) for GCode creation

-Carbide Create (free) for design and GCode Creation

-Fusion360* (free) for design and GCode creation

-Inkscape (free) for image design

*Fusion360 is the real workhorse, here. It has by far the most features, but also the steepest learning curve. If you’re familiar with Fusion360, you’ll have no trouble. Otherwise start with Carbide Create.

As an engineer I am impressed with the quality of this machine! Works very well

Ich habe mir Dezember 2020 die CNC 3018-PROVer bestellt.

Die Maschine wurde super schnell geliefert. Alleine die Verpackung (Schutz der einzelnen Teile) hat mich direkt berzeugt. Der Zusammenbau ist wie beschrieben sehr einfach und durch die hohe Fertigungsgenauigkeit hat alles perfekt gepasst.

Die erste Inbetriebnahme war ebenfalls sehr einfach. Die im Lieferumfang beinhaltete “Candle” Software ist leicht verstndlich und gut zu bedienen.

Die beiden Musterfrsungen (Schriftzug sowie Wagenrad) runden das Bild der Maschine fr mich perfekt ab.

Demnach kann ich die Maschine nur empfehlen!! :-))

This is the first review I have ever wrote. This is spot on for beginners. I read lots of reviews before buying this. Seriously download Easel and the this just a dream. The part that sucks is the putting it together. Lots of small parts(screws). I feel that they could have a symboled most before you get it. On the other hand at least you learn what does what if you put it together. 5 stars all the way. 30 minutes to put together. 5 minutes to get it running if you already have the program downloaded. This is my first CNC.

Sehr gute einsteigerfrse.

Einfach zu montieren auch fr einen laien.

Macht einen sehr stabielen eindruck und ist gut verarbeitet.

Fr den hobby bereich echt super.

Wer was groeres frsen mchte muss leider auf grere und teuere frsen ausweichen.

Ich persnlich bin sehr zufrieden.

Werde demnchst auch mal den passenden laser dazu ausprobieren.

Hi guys

I bought this router in January and would like to say a few words about my first experience.

Ease of assembly

You will have no problem. It’s really simple. There is a manual and there is a YouTube video. I spent about an hour and it was stress-free.

Ease of first use

It’s fine.

Before buying, I was worried about how well it worked. In vain. This is a truly wonderful invention. Thanks to the engineers.

And I didn’t expect this complex machine to be so easy to control.

Within one hour I learned to work with this router and again had no problems.

Problems start with the software “Candle”

It is assumed that we all buy a CNC router to create something especial. And this is where the problems begin. If you want to do something that has more than four corners, be prepared to grapple with obstacles.

The seller offers software that turns your idea into machine codes. This is Candle. I have not been able to figure out how to use this software. Please note that in the YouTube video someone is using Easel, and not the supplied Candle, which is part of the kit of this router.

The complexity of the proposed Candle is high. There is no technical documentation for Candle. Moreover, the supplied Candle does not perform the operations shown in the YouTube video. Try uploading your image or picture from your file…

Now I use Easel which is easy to create images. This Easel was created for another router. I spend a lot of time creating any image all the time.

Easel often loses the rotation speed of the router and I have to create new files. Easel often does not recognize the text as a whole object and I have to start over an old project every time. But Easel at least creates files for carving.

Excuse me sellers, but if you offer software like Candle then this should have a manual. Without a detailed technical description for the software, this router often becomes not a smart machine but a piece of iron.

I gave 5 scores to this router. Without a doubt, this CNC router is the best in its class of small routers.

I can’t give 2 scores to the supplied software just because it is free according to the seller. No problems.

I hope my opinion will be useful for people who is decides to buy or no this router.

I bought a SainSmart as my first beginner cnc/engraver. When I first received it I was completely clueless on what I was doing. As I began the build I found SO many helpful videos and it basically walked me right through EVERYTHING! They made it so easy to get it up and going. After several uses I found myself already ready for an upgrade so I purchased another motor from sainsmart because I already loved their product. This time I had to contact customer service because I wasn’t sure about what I needed to do for the upgrade. Customer service was awesome! They walked me through everything and did all troubleshooting with me to get it back to running. Not only do I highly recommend them for their product but their customer service is out of this world! I can’t wait till I’m ready for my next upgrade to a bigger faster machine this time with a laser. I’m going straight to SainSmart to get it!!

Very nicely build but small. Looking at upgrading to a larger bed.

Es una pequea maravilla que te puede hacer todo tipo de pequeos trabajos, desde cortar piezas a medida en aluminio, madera o metacrilato, hasta realizar tus circuitos impresos directamente tallados en el cobre.

No es fcil de montar y su manejo requiere aprendizaje. Has de aprender a usar las fresas adecuadas y de calidad para lo que quieras hacer, pero una vez que comiences con ella, o vas a poder parar!.

Tiene algunos defectos, como un motor poco potente (aunque bastante silencioso) y un cabezal de plstico, aunque ambas cosas se pueden actualizar a mejores componentes en la tienda de Sainsmart. No ahorres tampoco en fresas y vers la diferencia. Tambin se le puede acoplar fcilmente el mdulo lser para que tu vena artstica se pueda hinchar a tope.

Una compra de la que estoy muy satisfecho y el vendedor muy profesional.

Puede que no sea la CNC ms barata, pero huye de las imitaciones, esta es la autntica Genmitsu!

Y oye…es preciosa!

Gert tut was es soll, ist leicht aufzubauen.

Schade ist, dass das optional angebotene Laser System nicht zu diesem Modell passr, sondern nur zum Vorgnger. Das muss deutlicher in der Beschreibung zu erkennen sein. Auch sind die Hinweise welche Oeler geeignet sind unzureichend. Hier muss gebastelt werden und Improvisation fhrt i.d.R. zu schlechten Ergebnissen.

I use Kicad for circuits but had to download Flatcam to convert these to g files

I tried inkscape for general work but ended up buying cut2d which works great with it.

for 3d items I use cut3d which reads my stl files from Alibre Atom 3D cad package.

This CNC milling machine is great for what we need

It took 3 hours to setup by two people working together instructions are printed and very good

Once machine was setup easy to test and use with great results

The software is PC only included with the machine as we are Apple Mac Users we spent a few hours online finding some great tools to use with this machine. We also updated the firmware with the new GRBL firmware from the open source site with ease

Assemblaggio semplice e ben descritto.

buon prodotto per quello che deve fare.

I have not been disappointed!

With clear instructions and basic components, assembly was a breeze. Unfortunately, over off the limit switches was broken. No big deal. It happens. When I reached out to buy a new one, they insisted on replacing! Free of charge!

They even followed up with emails to make sure assembling was complete and I was completely satisfied! You don’t get better customer service than that.

In the meantime I have made great strides in the learning curve and I am truly enjoying the process! If you’re thinking about one of these guys go ahead and pull the trigger you won’t regret it.

So far so good. It takes tweaking but eventually works well. Good buy for the money

Der Aufbau ist gut beschrieben und in ca. einer Stunde erledigt. Das Einfdeln der Kabel in die Kunststoff-Netze ist etwas fummelig, mit Geduld und einem Feuerzeug aber auch sauber machbar.

Die Spindel ist relativ laut, luft aber sauber zentriert und bisher sehr zuverlssig. Der Motor lsst sich auch gnstig nachkaufen, falls etwas wre. Der Bewegungsapparat hat viel Kraft und ist sehr przise, die Steuerplatine ist sauber verarbeitet und bereits mit einer vorkonfigurierten GRBL-Version geflasht. Nach dem Aufbau kann es also direkt losgehen.

Als Software wird eine ltere Version von Candle mitgeliefert, ich habe mir gleich die aktuelle Version von Github geladen. Damit lsst sich die Frse sehr gut steuern, auch eine 3D-Vorschau und eine Heightmap kann erstellt werden. Ich habe mir noch eine zweite Krokodilklemme an das Kabel gemacht, um PCBs sauber ausmessen zu knnen. Fr die Planung verwende ich meist Sprint Layout, als Prprozessor dann FlatCAM.

Fr das Isolation-Routing benutze ich ein 30 V-Bit mit 0.1mm Eintauch-Tiefe, dann einen 0.5mm Frser fr die Lcher und einen 2mm Frser zum Herausschneiden. Bisher habe ich ca. 20 PCBs erstellt, die Genauigkeit ist auch fr SMD absolut ausreichend. Fertige PCBs sprhe ich dann noch mit PCB-Lack ein, um sie vor Korrosion zu schtzen.

Auch Holz lsst sichgut bearbeiten, am besten geht natrlich weiches Material, aber bei entsprechend langsamerem Vorschub konnte ich auch mit Eiche gute Ergebnisse erzielen. Die Planung und das Erzeugen des Maschinen-Codes habe ich dafr komplett in Autodesk Fusion 360 durchgefhrt, aber auch andere Software, die GRBL kompatiblen GCode erzeugt, kann benutzt werden. Die Reinigung ist aufgrund der schlanken Bauweise unproblematisch, und die mitgelieferten Verschraubungen halten das Werkstck sicher auf dem Tisch fixiert. Ich habe mir noch kleine Gummife gebastelt, damit die Schrauben beim Einspannen das Aluminium nicht verkratzen.

Die maximale Breite des Werkstcks wird durch den Rahmen seitlich auf ca. 30cm beschrnkt, nach vorne und hinten ist die Maschine offen und hat in der Tiefe einen Arbeitsbereich von ca. 18cm. Die maximale Hhe liegt bei etwa 5cm, hher kann die Spindel nicht angehoben werden. Fr Namensschilder, kleine Formteile und natrlich PCBs ist das meist mehr als ausreichend.

Fr den Betrieb empfehle ich ein dauerhaft verbundenes Notebook, da man damit die beste Kontrolle und eine Vorschau hat. Mit dem mitgelieferten Controller kann man die Maschine zwar auch bewegen und GCode senden, durch das fehlende Feedback sind die Mglichkeiten dann aber eingeschrnkt. Die Endstopps halten die Maschine bei Bettigung sofort an, dadurch wird verhindert dass man eine der Achsen zu weit bewegt und damit mglicherweise die Mechanik beschdigt. Auch ein Homing ist dadurch mglich, wobei man gerade bei dickeren Werkstcken aufpassen muss, dass der Frser nicht an den Halterungen hngen bleibt. Auch der Not-Aus-Schalter ist ein praktisches Feature, weil man damit die Maschine vor einer Kollision oder bei einem abgerissenen Frser sofort anhalten kann und Schden vermeidet.

Insgesamt eine sehr vielseitige kleine CNC-Frse, auch gut fr Einsteiger geeignet, fr gute Ergebnisse muss man sich allerdings vertiefend mit CAM-Software auseinandersetzen und braucht in der Regel mehrere Versuche.

I noticed that the Amazon page says this machine is pre-assembled. The one I received was partially assembled and I had to attach the sides and gantry to the bottom frame. Putting this CNC together, if you’ve never done this before, should not be rushed. Take the time to make sure every part of the frame is square and nothing binds up when it moves. If you don’t do this, you’ll have problems, guaranteed. While a couple tools are included in the box, I would also recommend a straight-edge, a tape measure and some extra small zip ties.

While the instructions can get you by for assembling this, there is at least 2 excellent videos on YouTube that will make the entire process much easier. There was a little learning curve in just figuring out what parts were called what. The video makes that pretty straight forward and also shows you some extras on how to calibrate and get the machine ready for your first cuts with CNC.

For a CNC newbie (like me), there is a learning curve. Some would consider it steep, while others figure it out pretty fast. This unit, and larger CNCs use GRML as their operating system. It’s not too complex but its also not obvious what each command does to the machine. There is a lot of GRML info on-line and the time spent there will move you closer to making life easier with the CNC. Sain Smart also maintains a Facebook group for users of the 3018 machines. Some of the people on that forum are experts and it’s worth your time. If you’re having an issue, you’ll usually get a answer real quick. Lots of very helpful CNC users.

I want to say something about the Customer Service part of this because it’s worth mentioning. I had a small part fail on day 2 of using the machine. The customer service was quick to respond, we had a quick conversation and a new part arrived at my home within a week. So far, I’ve had nothing but positive communications with Sain Smart about my machine. Responsive customer service is one of the reasons I bought this version of the CNC.

I would recommend this particular version of the 3018 CNC to anyone interested in learning CNC work. While there are many offered on the Amazon site, Saim Smart has a very good reputation and that makes a difference sometimes. Sain Smart put together a good package for sale and they offer a lot of options, upgrades and other items to keep your machine working all the time. Great way to learn CNC work. Price was right too!

Love it! A little tricky to get started at first but once you’ve got it its amazing!

This was more than just buying a good product! I received support above and beyond any I have received from any company delivering consumer products on Amazon or elsewhere. Background: I purchased SainSmart Genmitsu CNC Router Machine 3018-PROVer in November. I was regularly notified via Amazon of delivery progress – all very normal. I received the machine assembled and tested it according to their written and video guides. Everything worked perfectly when attached to a computer via USB. However, the off-line controller did not function properly. To resolve this I contacted Amazon support. Amazon tech support walked me through analysis and determined I need to work with Genmitsu directly. This is where support went crazy GOOD! It began with a chat session that evolved to a couple of email messages resolving to Genmitsu replacing the controller, during the run up to Christmas, shipped from China! I received updates both from Genmitsu and DHL on the shipping status. The controller arrived just after Christmas and worked just fine. So the problem was resolved. The resolution time frame and support contact exceeded my expectation.

I know what good support should look like. I retired from a forty-year IT career as a Senior Product Manager in a well-known three-letter company. Genmitsu support is the real deal and the quality of the product appears to be right up there as well. Recommended!

Great product for starters. Comes with all the instructions. Customer service is great.bhad a little issue but they resolved it quickly.

Its worth the price

First, you are buying from a real company, with a real warranty, and excellent customer service. Their online documentation and Facebook group will get you up and running even if you know nothing to start. I had a few minor issues with my machine,emailed their customer support, and they had a replacement part to me within days.

Second, this machine has everything you are going to end up adding to your 3018 anyway. Limit switches (lighted so you can see which one triggered), z axis probe, emergency stop. But what the specs don’t show is the build quality. The frame is aluminum not plastic. The stepper drivers are nearly silent. The x-z carriage is injection molded not 3D printed. The Z axis bearings are single 35mm linear bearings not two cheap 15mm ones stacked. Etc, etc…

This is a fantastic little machine. It is still a 3018 though so be patient with it. It isn’t going to machine steel or crank out aluminum parts in minutes. But it will do small projects with great accuracy. Awesome given the low price.

Bonne petite machine facil a utiliser rien a redire pout le moment, je recommande

During my Email conversation with SainSmart, I have made some suggestions for the improvement to the machine’s design, that they are now thinking of implementing. The improvements is fitting a slide plug socket connection box to the front of the unit, to bring out the z-probe connections. This box is fitted with an LED indicator, to show that the z-probe is working. The box attaches using the existing threaded holes in the case and the wire is run along with the other sensor cables. The box connections allow the user to plug in the z-probe puck or a crocodile clip and ground return for z-probing mapping of the PCB surface.

My CNC recently developed a fault, which I reported to SainSmart under its guarantee scheme.

I have been very pleasantly surprised with the speed, courtesy and and friendly customer technical support. Having emailed proof of purchase and pictures/video of the nature of the fault, involving an email dialogue with a SainSmart support engineer . A replacement part is being sent to me from China at no cost to me. If only other companies provided this level of customer service.

Assembly took about 30 minutes and was straightforward. Everything fit, had extra screws.

The candle software it comes with is very simple, yet powerful. The offline controller is outstanding.

The software to generate files was a bit trickier, which is understandable, since that’s not included.

As a favor to all others- I used “Inkscape”, a free image editor to create dxf files from images I wanted cut out. I then imported the dxf files into “estlcam”, another free (within reason) program that would then generate the gcode file, which could then either be loaded into candle for operating with a computer, or dropped directly onto the sim card for offline mode.

Overall, very impressed, I like it very much.

ER11SDXY

DC5.5/2.5mmZ3D

LaserWebInkscape”Object to Path”LaserWeb”Mill Pocket”LaserWebGrbl $10=3 $10=0 $20=0 Fusion360

: 100MDFFusion360LaserWebz-probe1

Montata in 2 ore, istruzioni solo in inglese ma gli step di montaggio sono semplici e aiutano molto le fotografie.

La macchina lavora bene, essendo una macchina da hobby risente molto delle vibrazioni, ma con alcuni accorgimenti sulla profondit di passata si comporta molto bene.

Il mandrino da 10.000 giri in dotazione ottimo anche se per i miei lavori non sufficiente, ma ho trovato il ricambio da 20.000 giri che sar il mio prossimo acquisto.

I bulini in dotazione sono basici, vanno bene per le prime prove ma non si pu pretendere troppo.

La macchina un gioiellino ad un prezzo accessibile.

La consiglio a tutti.

This is a great beginner CNC machine. Takes some time to get it dialed in correctly but once you are past the learning curve it’s a lot of fun to use. It’s a solid little machine too.

I had an issue with the Z axis carriage but after contacting SainSmart they sent me a new one free of charge. The customer service is truly exceptional as Hong helped me out a lot and followed up to make sure that everything was good.

This machine was well worth the money and perfect for what I needed.

I am very happy with this product and the excellent customer service I received when I contacted them over a minor issue which was quickly and efficiently resolved.

Che dire,ottima per imparare e fantastica anche per futuri lavori.La solidita del telaio e’ impressionante:

due singoli pezzi che si montano tra di loro preassemblati.Ben imballata e protetta abbastanza semplice da montare in poco piu’ di un ora e mezza (cavi ed elettronica).

Le funzionalit di homing e gli switch permettono di evitare danni alla macchina e ai pezzi in lavorazione.Utile il probe per fare lo zero ed il pulsante di emergenza che abbinato al controller offline la rendono totalmente indipendente dal pc.La scheda e’ basata su Grbl 1.1 e i gcode possono essere inviati tramite candle (o USG) con pc-usb o tramite il controllo remoto con una sd card.

Ho messo 5 stelle, perche’ oltre ad essere una macchina ben costruita e solida, ho trovato impeccabile la disponibilit ed il supporto tecnico. Ho contattato SainSmart per un problema al controller remoto. Prima abbiamo fatto dei test insieme ma appurato che era difettoso me ne hanno spedito uno nuovo in meno di 3 giorni.Poche volte sono stato seguito ed aiutato da un assistenza cosi efficace e disponibile.

Grazie SainSmart.

Impeccabile anche amazon ed il venditore,consegna con un giorno di anticipo.

The machine is well packed and most of the small components are well displayed within a small container. I use the machine to demonstrate my cnc software that I write for various cnc controllers.

Brilliant little machine but remember it is a d I y cnc and all the problems I encountered were user error would recommend you buy some good cutters and enjoy

One important thing to mention is that I had to modify the Z-axis. On the first few attempts I had an issue with the vibration and force wiggling the pressed in lead screw nut out of place. I ordered some new lead screw nuts and cut them down to fit in the groves and it fixed this issue but there is more play/wiggle in the vertical motion that I would like.

The upgraded spindle seems to do a good job of cutting through the aluminum without getting bogged down at all but there is too much play in the axes so the cutting depth is limited by the construction of the unit.

At this time I have been creating vector images in Adobe Illustrator, saving them as SVG then modifying them in the – free online – Easel program to create the G-code cut paths.

Within Easel I have my aluminum cut settings dialed to:

Feed Rate: 5 in/min

Plunge Rate: 2 in/min

Depth per Pass: 0.005 in

With these setting it takes 5.25hrs to cut what I call a “puck”; last two pictures. This puck consists of a 1.25″ circle with a 0.6″ stepped circle and 1/8″ drill through at 0.5″ depth A set of 4 pucks takes 21.5hrs to cut.

Pretty well made unit. Takes a little skill to assemble. The learning curve to use it is another story. Its not plug and play. You can really go down the rabbit hole learning about how to operate it if you want to. Theres a lot of programs both free and paid to use for design. 2d stuff is not too hard if you have some computer savvy. Lots of video out there to help and forums on the web. I will say, it works well. Pick up an assortment of bits if you want it to do more.

PCUSB

Candlefirmware

Candle(Grblcontorol)

X3

XYZ4

sainsmartSOUZOU

300WDstl

SOUZOU

The images I shared are of some early test pieces, not touched up (they are all early test pieces because we are 100% new at this and have only been working on learning it for a week).

It is a bit of a learning curve. Many videos were watched–none was the “magic bullet” of learning. But we did find that Easel was the best program for us beginners to get started.

We are very happy with the purchase!

I was very excited to get this product, I assembled it relatively easily, honestly not sure why people complain the directions for this thing is great compared to other things I have bought. Sketched up something in Fusion360 to test it out, it took me a little while to figure out the G28 command was why it kept running into the z stop at start up. I had a couple instances of hearing the motor over torque noise as it traveled under no load and even loosening and re tightening that axis didn’t change much. Finally the x-axis driver died before it even touched the wood. Just homing itself was too much for it. I have contacted customer support and hope this gets resolved soon.

The instructions were well written with large color photos showing how to assemble the device. This must be a newer model than some reviewers got, as the bed and upper assembly were fully assembled. I timed my assembly time, and from start to finish took about 50 minutes, and I took my time.

The device powered up and functioned properly from the first time it was plugged in.

Next step: Make the software work — I’ll add more to this review after I’ve laser etched something or routed a design. So far I am deeply impressed with the quality for the cost.

Great beginner cnc. I have used it quite a bit since I got it.

Nach einen monat board defekt.

An verkufer geschrieben.

Bis jetzt keine antwort.

While I think I’m pretty adept with it comes to shop tools and technology, I’m not very familiar with operating a CNC mill. I ran into a few challenges in the first few weeks and reached out to the SainSmart support team for help. They came back with solutions pretty quickly. Beyond tech support, YouTube videos and the Facebook group have been really helpful at getting me up to speed.

I was already familiar with modeling in Fusion360, so I’m using that to generate gcode as well. There’s been a fair amount of trial and error learning to run parts with the right tools, feed rates, etc. That said, I’ve mostly ignored the offline controller and am relying completely on Candle for running the machine. I’ve got that running on a RaspberryPi that stays permanently connected to the machine. This leaves my laptop free from being tethered in one place.

My primary interest is in milling wood, so I’m starting to accumulate/experiment with a number of bits. Some parts generate quite a bit of dust, so I think an enclosure and 3D printed dust shoe are in my future. I’d also like to be able to run parts faster, so I see myself investing in a larger motor at some point as well.

Second thing you’ll want to do is to resurface (face) your spoilboard. Do this, and you won’t need to fiddle with autoleveling the entire PCB or anything like that when milling PCBs. Also, your engravings and woodworking will come out beautifully, same with laser engravings and the like.

While the integrated offline controller works okay, this mill is best used with a PC so that you can accurately reposition the toolhead during tool changes. The integrated controller doesn’t do a good job there. The depth probe works very well, make sure to replace the included GCode with updated GCode from the manual. The stock probe height is 14.19mm, but I found that mine is actually closer to 14.35mm. Be sure you use a good caliper to measure it.

By far the biggest learning curve is setting up your CAD software (e.g., Fusion 360) to work with the mill. However, once you’ve done it, this thing is super reliable! Same for figuring out things like KiCad – you’ll want to make things extra “chunky”, by using extra large pads and making your traces larger. I was able to do 0.2mm traces, but those aren’t reliable. Instead, I just set 1mm trace sizes and 1mm of clearance, and every board has been perfect. I know it’s not ideal for large-scale integration, but that’s the wrong application for this mill.

Ultimate verdict is this: Take the time to learn this mill’s limitations and how to best get it set up. Once you do, you’ll be quite impressed. It’s easy to set up (the 15 minute setup is nonsense – budget at least an hour), tolerances are quite good, and like I said, it reliably does what you need it to do. At this price, it’s impossible to beat this machine!

Maximum actual usable bed size is 280mmx160mm before you hit end stops. Z Axis Nut fell out of plastic Z axis carriage within the first five hours of use scarring the bed as it was cutting at the time. It had to be heated and press melted back into the plastic holder, then epoxied to keep it from coming loose again.

With that being said, it does work fine for milling wood and thin metal so long as you don’t need your full bed. All in all a good starter unit to get the hang of CnC work.

Il prodotto ben impacchettato, tutto tenuto ben fermo da spessi strati di polistirolo. Unico difetto, nella mia scatola dei bulloni ne mancavano 2 M6, ho contattato il supporto SainSmart che me li ha recapitati in meno di 4 giorni.

Il montaggio semplificato rispetto ad altri prodotti ma richiede comunque un certo tempo, io ci ho messo circa 1 ora e mezza a completare tutto, e non ho messo il proteggi cavo in nylon perch mi riusciva male. Sono comunque molto soddisfatto perch le risorse fornite (sul sito sono presenti anche video tutorial) aiutano moltissimo e non c’ nulla da fare di veramente complicato.

Una volta montata la CNC si presenta esteticamente molto bene, solida e con un colore azzurro che mi piace molto.

Io la vorrei utilizzare principlamente per produrre circuiti stampati di progetti DIY, le prime prove mi hanno dato molta soddisfazione anche se ho ancora molto da imparare!

Nel complesso la consiglio a chi ha tempo e voglia di imparare e studiare le varie tecniche/tecnologie per la fresatura con la CNC, lo sconsiglio a chi invece preferisce avere una soluzione “plug&play” che faccia subito tutto bene senza bisogno di metterci le mani.

Allego qualche foto, scusate per la mia scrivania super disordinata 🙂

==== Automactic tranlsation in English ====

The package arrived a few days in advance, which left me very happy.

The product is well packed, everything is held firmly by thick layers of foam. One defect, in my bolt box there were 2 M6 missing, I contacted SainSmart support which delivered them to me in less than 4 days.

The assembly is simplified compared to other products but still requires some time, it took me about 1 and a half hours to complete everything, and I did not put the nylon cable protector because it was bad for me. I am however very satisfied because the resources provided (there are also video tutorials on the site) help a lot and there is nothing really complicated to do.

Once mounted, the CNC looks aesthetically very well, solid and with a blue color that I really like.

I would like to use it mainly to produce printed circuit boards for DIY projects, the first tests have given me a lot of satisfaction even though I still have a lot to learn!

Overall, I recommend it to those who have the time and desire to learn and study the various techniques / technologies for CNC milling, I do not recommend it to those who prefer to have a “plug & play” solution that does everything right away without having to get their hands on it.

I attach some photos, sorry for my super messy desk 🙂

After playing around with the machine for a bit I decided to reach out to SainSmart about the issue with the hold down. Hong at SainSmart was phenomenal at helping us out, a few short emails to verify which part was missing and a replacement was on it way. When it arrived, shipped July 7th from China arrived July 10th Canada, I found a complete hold down clamp set! Hong kept in touch with me right up until I received my replacement part.

Thanks Hong!

If you plug it in and it connects to Candle but nothing works make sure you check your emergency button. It’s a special kind of switch that’s spring loaded so you can’t pull or press to release. To release it you have to twist it in the directions indicated in the arrows before it will pop back out. I wasted a good hour on this step by not looking

carefully! Whoops.

I was also concerned about the amount of sound it would make in an apartment and was glad to find that if you can control some of the vibration it’s quiet enough to use without bothering the neighbors.

The software and manuals all worked fine and there was a copy of the software and tutorials on the included SD card for the offline controller.

Recommendations:

1) start with dense foam insulation as you can rip thru it without endangering the drill bit. Later, experiment with soft woods and such.

2) Find some slicer software to turn STL models into gcode. I found kiri:moto is free and works great. I have found that I needed to edit the top header of the gcode it created, but that was just copying and pasting the top few lines from the examples into the created gcode, replacing the startup sequence (easier than it sounds).

3) Learn a little bit about what gcode is. It’s a line by line series of commands that control the CNC. It’s all text and is pretty simple. Mostly, just know what the machines wants (everything measured in mm) and give it that. 🙂 Again, the supplied examples that came with the machine will help you figure that out.

4) the Candle software works great (and its cool watching it model the tool path), though I found it freezing up on long runs (more than an hour). I now make the gcode, offload it to the (supplied) microSD card, plugged it into the offline controller, and ran the file directly; no mid-mill faults with this method whatsoever.

5) milling generates a LOT of fine shavings. Have a vac or dustpan nearby. I decided to buy a plastic, translucent, container I can put over the whole machine while it runs, to help contain the dust and shavings.

6) The machine is pretty quiet. I have it running in the garage and when I enter the house, I can’t hear it at all. That said, I think the above mentioned cover will also deaden the sound a bit more (it’s high-pitched noisy next to the machine).

7) A bunch of engraving bits are supplied, but I’d recommend buying some additional end-mill bits if you plan to do milling with depth (i.e. not just cutting words into a flat plate) as the supplied knife-like bits aren’t the best for that task.

8) getting this slightly more expensive version with the hard stops and emergency stop button has already paid off. I can’t imagine getting a machine without those. I’d have ruined it with my first self-made gcode. That may be just me, but if you haven’t done milling before, get this machine to provide a modicum of forgiveness to your first solo runs.

All in all, I’m really happy with this machine! It’s an experiment, but a well-functioning one.

The materials provided are good: heavy and well-machined aluminum, acceptable quality electronic and mechanical components and fasteners. The 3018-PROver is not nearly as “assembled” as the purchasing data indicates. You can download the assembly video or the manual and see for yourself – there are a couple of hours of assembly work, and there will be much consulting of the online manual, the video, and this errata while you are at it. The three major subsystems are mechanically assembled, but have not had the electrical components, wiring and many little parts mounted, and two major subsystems need to be bolted together. And since the instructions leave a lot for you to figure out, if you’re easily frustrated: choose another project.

The PROver version is based on Open Source software and incorporates its own motion controller software: GRBL 1.1. It does not need to be connected to your computer while the router is cutting. Most people will use Open Source CAD software, which does not come with the unit.

There is also a “3018 Pro MX3” version which requires that you purchase the Mach 3 software for $175, has a different main controller board and a different hand controller, and requires a Windows computer to run Mach 3 while the router is cutting. The 3018 PROver is a better choice for most people, as it avoids this expense and complexity. Mach 3 is motion-control software, not the CAD software. You will still need to find that.

The 3018-PROver controller is based on Arduino. The main controller runs the GRBL 1.1 software developed for Arduino and comes with its own hand controller. Hand controllers for other models, like the one for the MX3 version, are not compatible.

Source code for GPL-licensed software in this unit is not on the SainSmart web site as far as I can tell, and it looks like SainSmart still needs to learn how to comply with the licenses to the GPL binary software they distribute, and directly distribute the source code on their own site. I do not know what differences exist from the GRBL 1.1 developer’s source, but I suspect some might exist for the hand controller.

This machine will be covered with chips after operation and will require some wiping down, including passing some sort of wipe inside of the T-slots. I will try to improvise a chip vacuum for mine, no such thing is available to buy.

To find the assembly video, search for Sainsmart Genmitsu CNC Router 3018-PROVer Build. A few hits down from the top of the search on Google, there is a wiki page for the device at wiki.sainsmart.com . You can also find this directly on the wiki, but the indexing is based on SKU numbers. There are assembly videos for other models on Youtube, which you might find helpful.

Most of the tools required for assembly are provided. In addition, you will need a wire cutter to remove two wire ties used as a shipping lock, and a container of light oil to lubricate the lead screws, and some electrical tape to wrap moving wires together.

You will need to download the manual and display it on a big screen. That is the only way you will be able to see the photos adequately to be able to assemble the unit. The photos are in a printed manual provided with the unit, but too small and too low-resolution to tell what you should be doing.

Here are the errata I noted during assembly:

Step 1: You will need to provide your own wire cutter.

Step 2: You are told to mount 6 wire holders, but the photo only shows where two of them go! The video is similarly unhelpful! The second two go on the opposite side, identically to the first two. The third two go on the outside of the frame, on the same side as the stepper motor, opposite the two installed inside.

Step 3: The four wire holders mount on opposite sides of the metal piece. The photos don’t quite show this completely.

Step 5 and 6: The long end of the distance tool is held against the back of the frame, inside the channel. The last slider nut should be against the end of the distance tool. Because of the distance tool, everything lines up well and the 12 bolts go in a lot more easily than I expected.

Step 8: The square projection on the slide nut goes outward.

Step 9: Peel the protective film off of both sides of the acrylic sheets. They are clear, tinted blue, once you do that. Hold the sheet so that it fits the shape of the leg of the Y-Z assembly. That is the correct orientation. Put the bolts through from the outside, and put the slide nuts on the other side by hand, one turn only. Orient the slide nuts horizontally, and then push the acrylic sheet to the channel so that the slide nuts insert into the channel. Turn the bolts, and the slide nuts will seat correctly.

Step 10: There is an error on this page. Where they specify the Y+ and Y- connecting wires, they actually mean X! The VER- numbers are correct, Y should be X.

The main controller is attached to two beams, each of which has four channels. The X- limit switch wire must be run behind the main controller along the top of the bottom beam, looping to the front on the side where the controller has the USB connector. The cover strip goes over the wire on the top channel of the bottom beam.

Step 11: It may be necessary to temporarily remove the wire holders next to the limit switches so that there is enough space to insert the plugs into the limit switch sockets. Put the wire holders back afterward.

Step 13: There are different plugs on each end of the stepper motor wires.

Step 15: By “black cover”, they mean the black plastic nut on the barrel of the emergency stop button. Remove that and the square lock washer. Put the switch into the plate, and then put the lock washer on the switch from the back, with the pointy corners facing the metal plate.

This button is unusual: push to stop, twist to release.

Step 16: Whew! A lot left out here! You are supposed to pass all of the Z wires through a piece of the nylon braided web to protect them from friction. But the piece I was provided, although it can be expanded somewhat, doesn’t expand sufficiently to do this. I wrapped the wires with electrical tape.

Operation

Before you connect the router to your computer, you can play with it using the manual controller. This is non-intuitive though. I noticed that the files included on the SD card would run into hard limits (trip the limit switches) if run with the router starting in the home position. You will have to move X, Y, and Z close to the center of their operation before starting.

The limit switches are confusing. If you are stuck on a limit, which is sure to happen, run the reset function. Move the stuck axis until it stops again – the limit switch will halt the system when it is set, and again when it is cleared! Run the reset function a second time. Then you can move the axis as expected. At this writing I am not sure if configuration will make this easier.