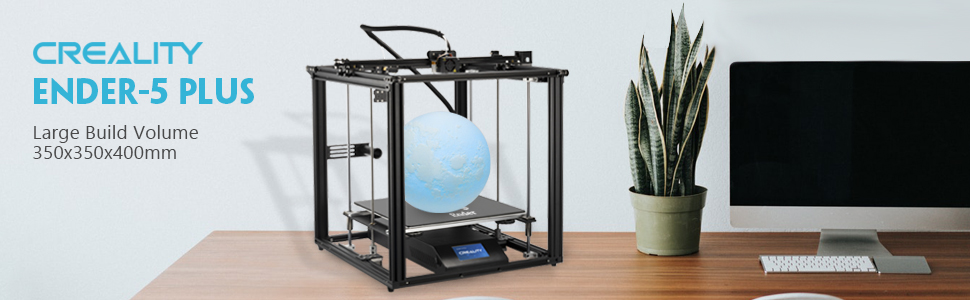

Official Creality Ender 5 Plus 3D Printer with BL Touch, Tempered Glass Plate and Touch Color Screen, Large Build Volume 350X350X400mm

High Precision Printing

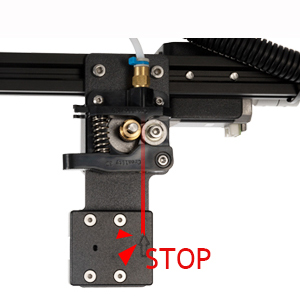

Auto Bed Leveling BLTouch. You will have a perfect first print layer. It offers Z axis leveling compensation, high rate of successful print.

Two lead screws in 2 sides of Z axis. The hot bed was held stably on Z axis in 2 sides, no bed wobbling and dropping, fewer points of failure.

Dual Y-axis Couplings. Use 42-48 motor, offer strong power support. Together with down-shift Z axis, make printing movement more smooth, ensure high precision printing.

Solid Large Cube Frame, Generous Print Volume(350*350*400mm). Meet more printing demands and ideas.

Other Parameters

- Modeling Technology: FDM (Fused Deposition Modeling)

- Mainboard: Creality V2.2

- Print Accuracy:±0.1mm

- Working Modes: Online or Micro SD Offline

- File Format: STL, OBJ, AMF, G-Code

- Slicing Software: Cura, Repetier-Host, Simplify 3D

- Fiament: 1.75mm PLA, ABS,Wood,TPU,Gradient Color, etc

- Nozzle: Standard 0.4mm Diameter

| | | |

|---|---|---|

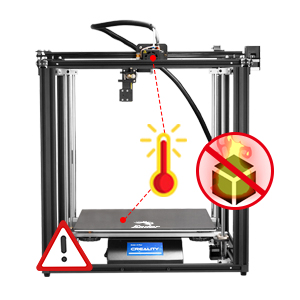

Resume PrintingContinue printing after restart.Help to protect power supply while achieving long time printing. | Filament MonitoringWith filament end sensor, printing will be paused if filaments run out, disconnect, or other abnormal conditions occur. | Thermal Runaway ProtectionIf the temperature rises out of control, the printer will stop heating and halt automatically. |

| | | |

|---|---|---|

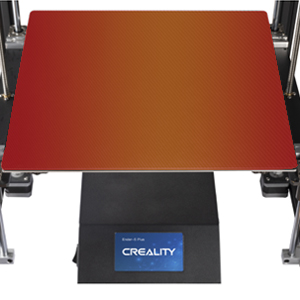

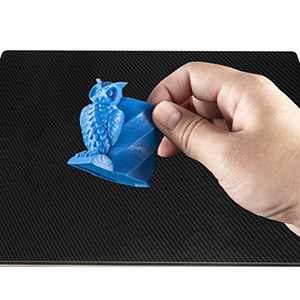

Quick Touch Operation4.3” HD touch screen, you can operate more quickly. More user friendly and time-saving. | Meanwell Power SupplyBrand power supply, safe and secure. Heat the hot bed up to 100℃ within 10 minutes. | Models Are Removed More EasilyAdd a tempered glass plate above hot bed, you can easily remove the models after cooling. |

| Dimensions: | 73.66 x 73.66 x 31.75 cm; 23.8 Kilograms |

| Manufacture: | Creality 3D |

| Origin: | China |

| Reference: | Ender5Plus-GMUS1 |

Great adhesion and arrived quick, some assembly required and cords arnt labeled well. Be careful when trying.

It came a day early. Amazon delivery is scary good. This is my first 3d printer. Its super fun and my 8yo son is getting excited about it which is really the best part. I designed a few parts in blender and there are also tons of free sites to get stl models.

Setup: Setup was simple aside from the diagram explaining where the spool goes but eventually figured that out. The one really (and I mean really) anoying thing was leveling the bed which needs to be done manually for the first time. It took a while to figure out that the glass plate is ever so slightly bowed up in the middle so dont strive for perfection. The bigger issue is the 4 knobs underneath the bed used for raising/lowering the corners to level the bed as pictured in the screenshot. They should have used a hex bolt or something because when you turn the nob in the attached image it also turns the screw making it impossible to tighten with the glass pane covering it. You need to insert a screwdriver while tightening but you cant level the bed without having the glass in place. I ended up putting metal shavings under the screw head to get some traction and that made life much easier.

Prints: Prints are as good quality as you can expect. Took a few trials to get good bed adhesion. Im using hairspray every few prints. Now I cant get the prints off the bed ;). Not a creality issue just a general 3d printing issue I guess. It helps that the bed is heated and there are separate controls for bed and nozle temperature.

Noise: Its a bit noisy but Im guessing that is just a general 3d pritner thing so not taking any stars away for it. Imagine the noisiest PC you ever built with several fans running 100% of the time. Thats how it sounds. Some of the prints take 12+ hours so keep that in mind you will have something whirring away in the background while you sleep. Maybe sure you have a separate room. Unfortunately its in the room I work in and cant have it running while on conference calls.

I have always been a very nerdy/ geeky person so when I started getting into 3D printing it meant that I could print out all the superhero, anime, and Star Wars stuff I wanted.

When I first got the printer it was broken but don’t worry because you have a month to return or replace it with Amazon and you have a year warranty with Cromgrow so when it came Slightly broken it was ok because I just replaced it for a new one that works amazingly.

I can print out mandalorian helmets in one go and make figures and other things really easily. One thing I couldn’t get to work that well was adhesion on the bed but in all honesty once I started using a raft or a brim it helped my prints a ton with adhesion.

things I recommend before you start to use:

-Watch Frankly Built’s YouTube video on the Ender 5+ assembly. It gives some insights to some questions you may have.

– buy better filament, personally I like sunlu PLA+ and it works great on the printer.

– the first thing you should do is to level your bed while the nozzle and bed are heated, metal expands when hot so level it when it’s heated up a little.

– The first thing you should print is a heat tower, you don’t want a nozzle clog or your filament to be too gooey so make sure to print a heat tower

– a retraction test is nice when starting out. You don’t need it that much but it’s nice to see how much you should retract your filament.

– remember that if your prints aren’t sticking try to use a raft as support it’s really useful and helps a lot.

– replace your bowdin type with a blue Capricorn one right away and replace your extruder with a metal one because the stock plastic one it comes with will break pretty fast because there’s always tension on it.

– and finally have fun printing, you got this! There are a ton of videos to help you with hardware and software issues and cromgrow has great support to help as well.

I really love this printer!! It did take me a couple of days to figure out how to level it. But once I did all my prints have turned out great. The touch screen is really nice and easy to use. I love the size of it because I can print bigger prints than the ender 3 and the 5 pro. I honestly think It was worth the extra money for it. I did do 2 upgrades (upgraded Bowden tube and all metal extruder feeder) from the beginning before I started printing just because I heard those 2 break super easy which is the downside of this print. I did wish it came with those already but it wasn’t too big of a deal for me. If you do struggle assembling it, frankly built has a great video on how to do it on YouTube. Overall I think this is a great printer.

Making a selection without guidance was difficult; however, I have been really successful creating in Fusion 360 and printing with this printer. CAUTION: instructions suck and are wrong! There are plenty of videos about setting up and using this printer. Watch them. I’m really happy so far.

All I can say is that I just got this thing to do one large print that my other printers couldn’t do. The quality blows my other printers away and one of them is a qidi. The speed is blistering too.

look, I read all the bad reviews and those situations suck. you are always gonna get a damaged product once in a blue moon. But this printer is blowing my freekin mind! I am going to ungrade it with some parts for convenience, but not cause it needs it, only cause I want to. Adding a magnetic plate is a must.

Having no issues so far. Worked well out of the box. Print quality is a little less the the cr6se but makes up in scale

I LOVE this printer! I just returned an Ender 7 Pro for sucking at all the things that THIS printer excels at. The Z-Axis bed is STABLE…….no drooping, dipping, or kicking. I ran the level calibration, made some adjustments to my levelling knobs, set my Z-Axis comp, and started printing. It took 5 minutes and this baby is painting ROPES! I never STOPPED adjusting Z, re-leveling, or cursing the 7 Pro.

The print bed on this thing is HUGE! Software is solid. Touch screen is crisp and responsive. PLA sticking to glass bed like it’s supposed to. I’ve FINALLY found my workhorse. A true “set and forget” printer.

At first, I was going to send it back it was not working correctly but after finding I had 2 wires backwards, I got it going and it works like a charm. so far, I only had it a few days and it is my first printer nut I have made several small prints learning the software and now I’m 46 hours into a 6-day print making my daughter a fnaf helmet.

I have owned two other printers from Creality for years now and have only had to replace one hot end on one of them. This one on the other hand is absolutely a LEMON, the Hot end and extruder have failed within 4 weeks of purchasing. The extruder/feeder snapped and the hot end had creep. So within a month I have had to upgrade about $100 worth of parts. Not including the material lost to bad prints due to failures.

Company stood behind product and warrantied out problem parts, They were quick and the replaments parts worked pefectly and I received them fast too!!!

Pour moi gnial rien de mieux une excellente imprimante seul bmol une lve de ventilateur casse pendant le transport et franchement pas envie de la renvoyer py

Der Drucker macht was er soll. Die Haftung war erst nicht so toll auf der Glasplatte, nachdem er jedoch richtig eingestellt war klappt alles. Allerdings hatte der Extruder nach sehr kurzer Zeit einen Defekt. Der Halter vom Antriebsrad ist gebrochen.

Le montage est nettement plus simple que celui de la Ender 3. Mais le rglage du plateau est un sacr jeu de patiente, ainsi que l’insertion du filament dans le tube qui se fait les bras tendus sans bien voir ce qu’il se passe.

Il faut faire attention aux deux moteurs qui pilotent l’axe Z qui peuvent se dsynchroniser si l’une des poulies a saut des crans. Vous vous retrouvez alors avec un plateau en biais que vous ne pourrez pas rattraper avec les vis sous les coins du plateau dont le jeu est insuffisant (dans mon cas, 2,5 mm entre les bords gauche et droit). Il faut donc remettre les courroies dans les bons crans la main. Vous tournez l’une tiges filetes (celles qui sortent des moteurs) en maintenant l’autre fixe et vous entendez la courroie sauter (imprimante teinte, sinon les moteurs sont en prise).

Ensuite, j’ai dbranch le niveau automatique que je ne suis pas parvenu faire fonctionner pour passer en manuel, avec le rglage des quatre coins avec une feuille de papier et les vis. Dans la vido du fabricant, ils disent que c’est inutile. Pas dans mon cas.

Il est quasiment impossible d’viter le wrapping avec les larges pices, mme en protgeant le plateau des courants d’air. La solution que j’utilise consiste imprimer un radeau dont je scotche les bords ds que la premire couche est imprime.

The Ender 5 plus is a very good 3d printer, that’s not to say it doesn’t have its problems cos it does. I started with the ender 3 then got the cr10s which I’ve had for a few years and have upgraded them both in that time. All the extruder on these printers have been crap and when I order a creality printer I know the extruder will need to be changed, you can get upgraded ones for around 15 so just order one when you order the printer and then you can fit it when you build the printer and then it’s done and it will save a lot of heartache in the future with failed prints, with a few upgrades on the ender 5 plus it is now an amazing 3d printer, I have printed a 5.5ft groot with this printer it is great, the box in the video was the first thing I printed with the ender 5 plus, I built the printer, leveled the bed downloaded the file and set it printing and was very pleased with the first pri

I love this printer but the stock main board and touchscreen are garbage.

After upgrading main board and installing klipper this thing is grea

The Ender 5 plus is a very good 3d printer, that’s not to say it doesn’t have its problems cos it does. I started with the ender 3 then got the cr10s which I’ve had for a few years and have upgraded them both in that time. All the extruder on these printers have been crap and when I orde

Great product. The wiring is a little messy but watch the videos on You Tube. Lots of good ideas

Dopo un lungo epistolario con il supporto della Creality e della Comgrow per la sostituzione (a pagamento) delle barre filettate dell’asse Z mi stato comunicato che il ricambio AL MOMENTO NON DISPONIBILE PER L’EUROPA.

At the price point this printer is at Creality left out some simple upgrades like all metal extruder, better bowden tubing and fittings, and silent drivers that would have made this a GREAT printer. Instead I had to spend more money making these upgrades that they could have included for just a little more cost and would have saved me a lot of frustration and downtime.

I received my printer and had a bad part after set up but the company was amazing at helping me to trouble shoot my issue and sending me a new part. Love my printer!

I love the creality printers I’ve been trying to build a business selling 3D prints and above all I recommend creality for any print type hobbyist to professional they are open source and I’ve tested other printers of this price range they just don’t compare!!!!

I have upgraded parts over time, but with a little effort we were producing pretty quality parts right away. The large print volume isn’t used often but it is nice to not have much limitation.

Easy enough to assemble if you have the mechanical aptitude. Leveling the bed was the most painful part but once it’s done, there are no worries. Heats up fast, prints great! I recommend upgrading the extruder, bowen tube and main board to the silent board if you are constantly in earshot of the printer. It sound nice for short prints, but it can wear on you for longer prints. Also, if you keep your home temp cool, bump the nozzle and print bed temp up a few degrees or you’ll have issues with bed adhesion. Once I got that tuned in, printing is a breeze.

FLASH FORWARD to the ender 5 plus!! After selling several of my prints, I finally had some cash to spend on a bigger printer. I took a look at the artillery sidewinder x1. Almost pulled the trigger on that but I saw some major flaws in it that reviewers didn’t like. So I got this printer. Let me tell you coming from an ender 3.. This printer was a dream to set up. Took less than 30 minutes (because I had experience from the ender 3) and I was up and running. First prints are these mugs in silk pla 0.4mm nozzle, 60 speed, 8%infill about 26 hours each. No estep calibration, no flow calibration, no glue or anything (glass bed is amazing!) just bed leveled using the auto bed leveling and z offset. As you can see, they look amazing.

Now for the bad stuff… Well not much that can’t be fixed.

1: It’s loud… Like.. Really loud. My ender 3 had a silent board and it’s a huge difference. My printers stay in a spare bedroom so it’s not that much of a problem. I may end up getting a bigtreetech skr mini e3 with touch screen at some point. But it’s not necessary right now.

2: no strain relief for the heated bed cables. Easy fix is to print one out from thingiverse. Super easy but it would have been nice if creality included that.

3: plastic extruder. Really? They can’t spend the 10 bucks to put an all metal one in these? For 600, I would expect that to be included. Got one and swapped it in. No biggie

4: the spool holder. I hate them I have a spool holder with bearings I use on the side. Again, not a big deal to me but still should be mentioned.

4: Bed leveling springs.. Terrible. Switch to silicone bed leveling mounts. With the glass and bl touch you’ll never have to mess with it again.

If you’re looking for your first 3d printer, the ender 3 is great, however, think long term about what you want to print. The amount of money you’ll put into an ender 3 you’d be better off getting this printer. It has the bl touch, glass bed, dual z, 350×350 print size, and a sturdy frame. I love it and creality knocked it out of the park.

UPDATE:

I still love this printer, however, I can’t understand why you pay so much money for them to put a plastic crappy extruder. As I always do, I was swapping it out with an all metal one. Not surprisingly, the plastic one was already cracked. I maybe used this printer for about 50 hours so who knows if it came like this or broke as I was using it.

So far the printer has been as expected. Putting together was simple enough with the help of YouTube. The printer is loud but it will end up in the garage soon enough so no worries there. It took a few extra videos and some tweaking to get the leveling correct, but seems good now.

These are amazing printers with great print volume and were easy to set up I had high school students build them calibrate them and run prints all a single day with no issues. You’re not gonna find a better picture out there for the money.

Facile da montare ma con qualche problema l sensore bltouch inizialmente

I’ve had a few 3D printers, but this is the first one with auto leveling. I was excited to get it, I thought my leveling days would be minimal, but that isn’t the case. Even after upgrading the springs to silicone bushings, I still have to level this ever few prints. I have an Ender 3 v2 with the yellow springs, I can’t remember the last time I leveled it, it’s been like weeks.

The printers been awesome, aside from leveling and a failed BLtouch (see below), everything I have printed has printed remarkably well, only one failed print, but it may have been my fault for moving it too close to the garage door and it was too cold and the print lost adhesion. Some of my test prints include a bridging test. The stl was only about 50mm, not much of a bridging test so I resized it to 150mm. That was pretty sweet to see. 20mm calibration cube was less then 0.05mm off on all sides. Stinging seem to be a slight issue with PLA, but I’m guess it was due to the speed, which is 80mm/s on the Cura’s default 0.2 profile.

Recently I had an issue with the BLtouch blinking red, I tried everything to get it to work. I contacting the company (in china), which I thought was going to be a long drawn out process. However, it was no, they replied promptly the next day with some instructions, and what to report back with. They’re sending me a new BLtouch to replace the one that come on the E5+. Very happy about the support quickness and their email instructions weren’t too hard to follow.

I’m new at 3d printing and this was easy to use.

I normally don’t write reviews unless a product is either so terrible that I feel I have to warn people, or so absolutely amazing that I really feel like I have to say something. This printer falls into the second catagory.

-The printer came in several pieces but took me around 30-45 minutes to put together (last printer I built was completely from scratch and took a solid day).

-I had my first print started within about an hour of opening the box

-I have not had a single issue with any of the prints I have done (with the exception of one print that failed due to my own fault of me not enabling a raft on a tall thin print)

-I honestly have not even bothered precision leveling the bed (with paper under the nozzle, etc). The auto-leveling before each print takes care of any small adjustment needed (although it does add maybe a few minutes to the print time).

I really don’t know what more to say. It does everything it needs to do. Large print volume, easy to use software, so far it’s been reliable, I honestly have not had a single issue with it. I technically could complain about the volume (the motors aren’t the quietest), but I did not buy this printer for it to be quiet. I bought it to print reliably, easily, and cheaply, which it does great.

This is my first printer and i am very happy, there is a learning curve so beware and its a cliff. This is a great tool to get started and you will learn alot just in the first hours. Be patient and give it a chance.

Appalling wiring. Stunningly poor. 0 stars.

very good stability mechanically easy to assembly, 5 stars.

very limited touch screen, seems to be buggy with the BL Touch. 2 stars.

Recommend to future buyers:

Get E3d volcano / v6 (the small one)

Replace screen and main board

replace extruder with aluminum and dual gears for extra grip.

Buy a 1 meter cable for the BL touch.

Above all else:

terrible wire and get the E3D volcano. for a large format printer its essential.

Amazon delivery was very frustrating, it took three time of out for delivery before it arrived. The printer was well packed so no damage. Assembly was fairly easy, less than an hour and that was double checking the sqareness of corners. Could use more instruction on wire routing. First run was bad. There is no documentation on setup. There are setting that are not obvious. Thanks to the YouTube stars I was able to get everything set and now it prints well. Use YouTube. Bed leveling is much easier on this than my smaller machine.

I have been printing with this machine for over three months and have had barely any problems with it. I don’t know if this is just for my printer or if it’s a common issue. So far the only problems are the runout sensor activating randomly (thus I removed it) and having to have the print bead slowly rise in temperature (ie set it at 60, 70, 75, 80, 85, etc), if you don’t you will get a temperature to fail and have to restart the machine. (probably due to not being able to heat up the bed quick enough but this was to get temps 75 and up on the heat bed).

Other than these issues it works flawlessly. I have done multiple 200 hr+ prints with no errors or layer skipping. It does heat up the ambient temperature of the room a lot. The design and sturdiness of the machine mean reduced ghosting in prints and reduced print failures due to a shifting bed.

I highly recommended leveling the bed every time you mess with the Z lead screws. What I do is lower all 4 corners of the build plate and manually level using the Z lead screws first using a level. This ensures both sides of the build plate are level since when you mess with the Z lead screws with power off it can become unlevel. After you do this you can do your usual manual leveling with a heated bed, then auto-leveling.

Also, your bl touch sensor will blink red sometimes if you start the machine in a position that the sensor’s probe cannot fully extend/retract.

Overall it’s a great machine and would buy it again. Just be aware of the slight issues and get familiar with troubleshooting filiment failures more then machine failures.

Ottima stanpante 3d, facile da montare, unica pecca le istruzioni all’interno non chiarissime per quanto riguarda la regolazione della stampante, ma basta cercare qualche video su youtube per regolarla alla perfezione. Consigliata.

I hated this printer when I git it, BUT after we (me and tech support) got the bed to level, then replace the mainboard then it works fantastic. it’s so great the way the print stick to the board. the print quality is wonderful

I have had the printer for a few weeks now and have managed to run it through it’s paces. This is my first 3D printer and I am confident in my choice. The inclusion of the BL touch is what sold me, in addition to the build volume.

After getting it dialed in, and getting that first layer looking smooth, my prints are turning out decent. This is a hobby printer so if you are looking for one you never have to tweak you’re going to be paying much more. I bought this to print small decorations around the house, but I have branched out into making some small parts I have come across on Thingverse. Once you get started you’ll find plenty of things to print out. Just be aware that it is a hobby and to have patience, and be willing to problem solve (that’s part of the fun).

This is my printer and it is working well. Arrived well packed but did have a little bent corner as seen in the picture.

Was able to fix it with some pliers. No problem. Took me maybe 3 hours to assemble and a couple of more hours how to figure out how to level and operate. In a couple of nights, I was making nice prints. Did update the printer with the “silent” board. Also pictured is operational power. Nice printer.

So from a strictly printer view point this thing is pretty awesome. The build volume accommodates a lot, the gantry setup allows for quick movement. The stock parts all work well IF you know what youre doing. The touch screen interface does limit access to some if the marlin features, its loud, and it eats up space.

The only real issue I had was with the shipping portion. One was lost, there were delays etc etc. There us also a large community support for this machine.

This was my first printer build so I was excited and a bit intimidated to unbox this.. I received it in the morning and was printing clean by the afternoon. There were some frustrating moments but they turned out to be “user error” there are many helpful videos online for walking you through build and starting up. Great printer.

If you are needing to print large then the Ender 5 Plus is rock solid. It takes a little to setup as it comes about 50% assembled but the instructions are good. Once assembled find the online video on how to correctly level the bed, part of this needs to be done before the bed is installed. Carefully read the assembly regarding the wiring as its not all explained as well as it could.

Ince setup do an aux leveling with a sheet of paper then do the measuring. It is a great printer. it prints consistently and produces very large high quality prints once you do the setup correctly.

I like the overall size. So far, I don’t have the print quality dialed in to where I like. Noticeable Z printing problem (seeing lines in the z direction), that is probably on me. I have to find out how to fix this. Overall, I am happy with the purchase.

First off this can print rather well, just take your time setting it up, getting the bed level and learn about the temperature and feed settings in your slicer software. Once you have this down you should have no problems trying to add a video but amazon is not letting me

Packaging: The box was larger than I expected, which isn’t bad but you should keep that in mind in case you’ve got tight space constraints or may need help moving it (I moved it alone). The printer was packaged very well inside high-quality, precision cut foam. I like it when companies put a lot of thought into the way their products are packaged, though sometimes I wish they would invest more effort into the product itself than showing off with a fancy single-use box. It takes some space just to unpack all the parts, and it is important to have enough room to keep things organized while you’re putting it together.

My biggest feedback with packaging is the box wouldn’t’ be that much larger if the printer were completely assembled and ready to go. If companies can produce other appliances like dishwashers, stoves, microwaves and dryers and find cost-effective methods of shipping them across the world ready to plug-and-play, then this ought to be something 3D printer companies could also easily do. I’d happily pay more for a ready-to-go product.

Assembly: The instructions provided were confusing, but there is a great video on YouTube which walks you through all the steps. If I had it to do over, I wouldn’t even look at the printed instructions. I got myself very confused by sentences with obvious typos which said “use 4 screws” when there were 8 of them and 8 holes, and then said “once all 6 screws are tightened” Some of the diagrams really lost me also -especially the one about mounting the spool holder. Rather, I’d just put the video on and follow along, pausing as needed.

It would be simple for Creality to put a link to this video right on their product page, but they don’t. That’s a fail in my view. If you try to follow the written instructions, there’s a much greater chance that you’ll end up putting something together incorrectly.

Again, it would be great if you could just buy a pre-assembled version like you can with so many other tools and appliances.

Operation: It took me a while, but I eventually figured out how to make my first couple prints. The instructions here are definitely lacking -probably with the assumption that you already know what you’re doing. I eventually learned that you can’t just print the files provided on the SD card. You must first install the Creality software on your computer, then load the files into Creality, and save them as Gcode.

You will ultimately want to use 3D modeling software which can export your models as STL files, which then need to be run through the Creality engine in order to print them. It would be great if the instructions explained this somewhere. Initially, I spent a bunch of time trying to figure out why the printer wasn’t recognizing the STL files themselves. I assumed that since Creality put them on the SD drive, that they were “ready to print.” Why not just provide them in gcode format on the SD card?

Noise: It seems that some of the parts could be better lubricated, which might reduce the sound of printing. I haven’t seen any instructions relating to this, and am nervous to use the wrong kind of lubricant in the wrong spot.

The loudest part of the process is at the beginning, when the X and Y axis calibrate. After that, it isn’t too bad, but certainly not something you really want to listen to if you have it going for long prints right in the office you’re working in. I set mine up in another room where I can close the door and thereafter don’t hear it at all other than the initial calibration noises.

I know that a cover is available, but I get the impression that it wouldn’t reduce the noise significantly, and doesn’t appear to be as rigid/robust/protective as I would ideally like. I originally intended to build an enclosure for it with wood and glass, but haven’t gotten that far yet. In thinking about an enclosure, it is worth noting that a dishwasher comes with a layer of insulation which wraps around the outside of it. This contributes both to noise reduction and to energy efficiency. The insulation forms a thermal barrier which keeps the heat inside the dishwasher as it runs. As someone new to 3D printing, I’m not sure what impact it would have to keep the printer in an insulated box, but I imagine it would either reduce the energy needed to heat the base and the nozzle, or would prevent things from cooling properly and cause damage. It would be great if Creality either produced a printer which came pre-assembled inside a more robust enclosure, or if they provided customers with tips about building their own enclosures to improve performance, reduce noise, and protect against dust, etc.

Problems: The Creality filament which came with the printer appears to be very low quality. It breaks often, and as a result, I was only able to print one complete object successfully with my whole first spool. Although there is a filament sensor to prevent failed prints, it doesn’t always work. It is very frustrating to set up a print that will take 8 hours or more and come back to find that a bunch of filament and time was wasted on a failed print. The closer you get to having it completed, the more frustrating it is when you discover it failed. I also did not find instructions for what to do when the filament breaks, and ended up figuring that out through trial and error.

(1) The spool holder is very loose and the spool just hangs on it. With how precise the rest of the machine is, I can’t imagine why there isn’t a more exact fit to hold the spool in place -maybe a well lubricated wheel with ball bearings that has almost no friction and keeps the spool perfectly aligned with the feeder, reducing the possible side movements and filament breaks.

(2) When the filament feeds into the filament sensor, it can get stuck inside of the sensor itself. The filament has a curve to it after being on the spool, and although the filament sensor isn’t very long, the curve of the filament can cause it to bend before going completely out the other side of the sensor. During one of my prints, the filament broke inside of the sensor, and although the sensor correctly indicated that the filament was present inside the sensor, there was no filament going beyond the sensor itself. This caused the remainder of the print to occur without filament -a failed print.

(3) When the filament leaves the sensor and goes into the extrusion motor, it can be difficult to get it to feed into the tube leading up to the extrusion head. The curve of the filament really just doesn’t want to allow it to move in a straight line along the intended path, so it can get stuck between the wheels on that motor and the hole where it enters the tube. If the filament breaks between the wheels and the tube, the part below the break will get stuck outside of the tube, but the filament sensor will still indicate that the filament is present -leading to a failed print.

(4) When the filament breaks, and you need to re-feed the filament into the tube leading to the extruder head, I’m still not sure how to properly do this in the middle of a print. I viewed it somewhat like a hot-glue gun, where when one glue stick runs out, you smoosh in the next one until there is glue dripping from the nozzle and until the new stick is far enough in that the feeder from the trigger can grip it. During my successful print, the filament broke before the filament sensor, which stopped the print. I was able to re-feed the filament through the sensor and push it through the feeder and into the tube to the extruder in order to continue, but it felt more like an awkward amateur approach than whatever you’re actually supposed to do.

(5) When I installed the Creality software, it asks me which kind of printer I am using. However, there is no option for the Ender 5 Plus. The whole purpose for getting the Ender 5 Plus is the extra print size, but because the printer is missing from the list, it limits you to the smaller print area of the Ender 5. There’s probably a software update somewhere that would fix this, but it is surprising to me that Creality didn’t bother to include the updated software on the SD card they provided with the actual Ender 5 Plus printer. This makes a problem for customers and creates extra steps/troubleshooting rather than moving toward a more complete plug-and-play product.

Performance: Although I am impressed with the quality of the prints, I am not at all impressed by the printing time. I’m new to 3D printing, so I know I probably had unrealistic expectations to start. I got the Ender 5 Plus specifically because of the large print area, with the objective of printing larger objects. I was somewhat alarmed to see that the print time for such objects can easily be more than 24 hours. Then, when you factor issues like repeat broken filaments or the possibility of completely failed prints -it could take way longer. Plus, if you’re trying to print something large, you may be looking at more than one spool of filament, which aren’t inexpensive. If you waste 2-3 spools on failed prints before you eventually produce one large object, that definitely factors into the cost of that object. From my entire first spool of filament, I got only one object, which definitely is not worth the value of the original filament. If you’re new to 3D printing, it might be worth just getting a smaller, less expensive printer and focusing on smaller objects. It is exciting to think about printing something that’s over 1 cubic foot, but when you realize how many hours that print will take, and how much filament you’ll go through, there may be another approach which is both faster and cheaper.

It is also important to note that the printed object will not have a perfectly smooth surface. I understood this going in, but assumed that I would be able to use fine sandpaper or files to smooth the surface, much like I did when building plastic models as a kid. The printed plastic is rigid enough that it can be tough to do this. For the one object I successfully printed, I spent quite a bit of time with an exacto knife, sand paper and metal files trying to clean it up. I’m not sure if this is the best approach. Someone mentioned to me that you can use heat to soften the surface to make it easier to work with, but I feel like that’s a difficult and risky method. It might work well to apply a thin layer of putty or gap filling primer which can be more easily smoothed and then painted. No matter what the approach, just know that unless you’re specifically looking for a rough, unfinished, and obviously 3D printed look (which certainly is cool for some applications), then you’re going to be spending a considerable amount of time on finishing work for each object you produce.

Filament: So far I’ve only used the filament provided by Creality. I’m definitely not impressed with it due to the frequency of breaks and the problems with the sensor and feeder. I’ve already ordered more spools from different vendors and am eager to try them.

As a novice printer, I have a possibly unrealistic dream that eventually I’ll be able to recycle plastic bottles at home by running them through a shredder and melting the particles into my own spools for use in 3D printing. I imagine that if someone were to create a machine which made this possible, it would make 3D printing more economically viable, and that it would help reduce the amount of plastic waste that humanity is dumping into the environment every year. It would probably also be really helpful to the companies which already produce filament, by driving down their production costs.

As it is, paying a lot for filament which may end up wasted on failed prints is obviously frustrating and not sustainable.

Economics: At the beginning, I had the thought that maybe I could help offset the cost of the printer by making things and selling them on Etsy or Ebay. From searching around a bit, it appears that other people do this, and theoretically earn enough from it to justify their efforts. Being practical, there’s definitely a learning curve, and a lot of research is needed to identify what to make that would be in high enough demand to justify the cost of doing it. Also, due to the extremely slow print rate, and the high cost of filament, it would be easy to lose money printing things that aren’t in high enough demand and don’t command a high enough price. If you intend to print stuff to cover your costs, it seems to be easier said than done. If your margins and volume are both low, then it could take a long time to break even, remembering that the printer itself has a limited lifespan.

However, if you’re just planning to print things for prototyping, and the production method would involve making molds of the 3D printed items which could then be produced faster and more economically, then that could work. There’s definitely a learning curve when it comes to producing effective molds and using them to produce quality end items.

If your goal is to start a business that makes a large volume of objects and sells them for a moderate margin, a pizza oven might generate a more reliable ROI.

Conclusions: I’m not sure if I will get the intended value out of the printer itself, but I do think I got a lot of value from the learning that came from it. Learning also takes time, and I’m still very near the beginning of this journey, so I’m feeling confident that the value I will eventually get from all the learning ahead will exceed the cost I paid for this, filament, 3D modeling software, and time.

Cant even test a print because the side voltage button is missing

Update: Be aware some unit doesn’t come with the voltage switch on the base 230V or 125V, it still works. I wish they would have put it somewhere. I lost 3 hours researching and going to a store to ask.

This is my second printer from Comgrow and can’t beat it for the price. Takes some fine tuning to get it just right but since it’s a kit I expect that. All and all a great printer.

This printer is much bigger than I expected. 2 small prints in and I’m addicted! This machine is very well built. The dual z axis and the box frame makes it incredibly sturdy. It’s about as loud as a small fan.

It took me a few days to really get the hang of this machine, but now that i understand it i love it. Unfortunately the silent board i was upgrading didn’t work correct, but the stock board is working great. I ordered a new silent board to upgrade later. The biggest thing i’ve learned is to level before every print. If you do that your golden. First you do the aux leveling, then do the measurement setting to dial it in. After that you should be golden.

Stuck at loading screen now….Not even a year. Removed SD card. Still stuck…

Update: after hours of rebooting and disassembling. The device magically started to boot right after I was about to give up. However this is still a reliability issue as I can no longer trust it as much as I trust my lulzbot.

Update2: It freaking happened again. Just stuck at booting. Great. So reliable.

Update 3: customer service sent me a new control board. It came back to normal. I guess my machine was the abnormality since it is such a popular machine on YouTube. Hopefully this is the only hiccup.

I love it was simple to put together a big learning curve for me but I’m getting there

Got some good prints out of it an some fails

But overall it’s a great printe

Arrived on time with no issues. Unboxing and setup was relatively quick. This is my second 3d printer so I kind of already knew what to expect while putting it together and didn’t really run into any issues. Have run a bunch of prints on the printer already and all have come out great (except the ones that I messed up, no fault to the printer) Honestly I have no complaints and if I had the cash would buy another one.

Packaged well, all parts worked on arrival. Instructions are a little vague and one plug was not labeled……but using process of elimination pretty easy to intuit. Looking forward to printing full sized monoprint cosplay helmets now

Set up and running was very easy. The bed leveling took time and still have to check it from tint to time. The auto level needs to change and suggest being turned off.

I wish they would allow the full Cura software not a half version, there a few good functions that would help in printing.

Size is of the bed is great, and printing has been awesome. Next upgrade is to do a detect drive extruder to do more filament types.

Update, 3/12/2020

Well after some back and forth emails with Cathy at Comgrow it was determined the mother board was at fault. Recieved the new mother board with in a weeks time and installed it and now everything is fine. Thanks again Cathy!

I purchased a the Creality 5 plus with bl touch from Comgrow thru amazon on 1/26/2020. The card reader never worked but I was able to get a few prints over the usb port. During the last print the bed drop down a few inches and was still extruding filament so I stopped the print and tried to restart a new print and the bed will not go up during the auto leveling. In reading some reviews it sounds like others have had the same problem and received replacement motherboard. How do I go about getting a replacement?

Great product! Super easy to assemble. Plus there is a lot of support on you tube. The big issues I have noticed is the cable management is not clean unless you print a few items you can find on thingiverse. Definitely print the heated supports on your first print and install immediately. The spool roller is smaller than the hole for the spool which causes some slop. The last is the bltouch. It doesn’t seem to work all that we’ll. It will get stuck and start blinking red. I had to pull the plunger and that kind of reset it. The leveling with the auto bltouch was quite a bit off. It’s better with the manual leveling. 3d printing is a bit complicated so I was expecting all this going in. It’s pretty quiet which was a good surprise. The print quality is great but you need to fix the spool problem I mentioned.

The PSU stopped working after a few minutes. I contacted customer support and they send me a new upgraded PSU for free. Other then the power supply no issues for me.

The extruder made from plastic is pretty much useless. They (Creality) sell upgrades for the extruder the quiet board, capricorn bowden tubing and several more. Once these are installed and with very high retract settings (6-8mm for certain materials) the printer works very well. Love the sturdy design, very easy assembly. Oh yeah and is very loud and noisy in stock form.

Wish they would offer a Pro version with all these upgrades they offer preinstalled. Would mean a lot less wasted parts.

Where to start.

So many issues from the first day.

You have to google how to format the card they send you just so the machine will read it.

Bed leveling is a nightmare

Adhesion problems no matter what we tried. We tried everything and spent money on all kinds of adhesives, re leveling the bed. different filament, changed the setting too many times to remember to try and get prints to stick to the bed.

Last straw was 5 weeks out the BLTouch just stops working which renders it useless.

UPDATE:. The seller,Comgrow, contacted me after this review to make it right. They even refunded my money for the bltouch sensor which I replaced. When purchasing these printers you may not get a perfect level bed and there is just going to be a learning curve in getting prints right. Though the manufacturer could have put more into this model, it can be a really good printer. Just realize you’re gonna put some work into it.

I changed this from one star to 3.

This beast is a great printer.

Excellent quality and has vary large build area.

The BLTouch helps with leveling (still need to double check it however).

Might not recommend it for a first 3d printer for someone – these are still hobbyist devices – and take some work to use – they are not plug and play like printers or toasters. Still an excellent machine (my 3rd printer).

Well started off with a bad stepper motor. Swapped with one from CR-10s and worked fine.

This is a very nice printer! It’s not perfect, but its something to build upon. Installation was a breeze, first print was near perfect, and the touchscreen is a lot better than others I’ve seen. Only thing I had a hard time with was the unit reading the .gcode files on the sd card.

Review Updated: Feb 3 , One day after the return period ended , the motherboard and powersupply fried.

It melted a cable hooked up to my usb port on my laptop.

Nothing moves anymore the screen blinks an then goes black.

I am requesting a replacement powersupply an motherboard through Amazon system but their email system is not setup correctly Amazon keeps sending my messages back as not deliverable to ComGrow.

In all good concious I can no longer recoomend to buy this model of printer, if the parts only last 30days that is not an acceptable risk for the price.

The printer was really easy to put together and had excellent build quality I printed five different items so far using the printer and everyone’s come out perfect I’ve not been this excited over a toy that I got for Christmas since I was a little kid and I’m an old guy now

I ordered this printer on a Tuesday, It arrived on Thursday! It was very easy to set up and is came with all kinds of helpful tools. My first print on this machine came out amazing! I would definitely recommend this company and this product!

Put it together, manual not great and youtube vids not great either. Did eventually get it hooked up.

So TL:DR, Should I buy this printer: Yes. For the money the is one of the best build volume/speed/quality combos I’ve found. You should however, invest in better slicing software and be prepared to have to intuit some vague instructions which were lost in translation.

When I received this product I got it built I found the sd card reader wasn’t reading the code files. I contacted the seller to reported the problem. I got a response back from them in just a few hours. I sent the email at 10pm central time. They offered to send me a new mother board so I didn’t have to tear down the machine and rebuild a new machine. I received the new mother board in 7 days. Cathy (was the csr) told me that it would take 7 to receive the new board. She was on point on that. I pulled the old board out and put the new one in. It worked just fine. I would buy from Comgrow again for sure just because Cathy and her help with resolving the issue. Thanks again Cathy you made me feel great on how you took care of this problem.

I really do like this printer. Assembly was a breeze. I was up and printing in an hour.

This thing is badass! Super easy to assemble and sturdy af. It barely even vibrates at full speed. If you use an sd card you need to format it and rename your toolpath if you use cura otherwise it won’t read the files. A little bit of a learning curve but as my 4th 3d printer I think it’s my new favorite.