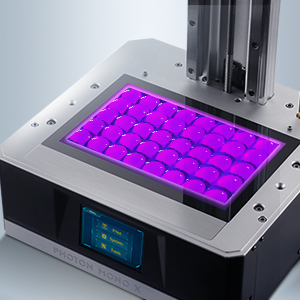

ANYCUBIC 3D Printer Photon Mono X UV Light Curing LCD SLA Resin 3D Printer with 3840*2400 4K Monochrome LCD Screen, Fast Printing and Wifi APP Remote Control, Print Size 192 x 120 x 250mm

| Weight: | 11 kg |

| Size: | 7.55″x4.72″x9.84″ |

| Dimensions: | 39 x 37 x 60 cm; 11 Kilograms |

| Model: | 7.55″x4.72″x9.84″ |

| Part: | UK-PMXA0BK |

| Colour: | Yellow |

| Pack Quantity: | 1 |

| Batteries Required: | No |

| Batteries Included: | No |

| Manufacture: | ANYCUBIC |

| Colour: | Yellow |

| Dimensions: | 39 x 37 x 60 cm; 11 Kilograms |

| Quantity: | 1 |

| Size: | 7.55″x4.72″x9.84″ |

first off i would like to state that i do not print resin items for a job, i am just a hobbies/enthusiast.

i have been using a Ender 3 Pro for a while now and i was becoming frustrated that i couldnt print super fine and high detail prints on it, i sorta walked into it knowing i wouldnt be able to, but still.

i spent a fair few months searching around for resin printers, pondering if it would be worth the purchase, comparing resin prints to filament prints online until i eventually had enough saved up to bite the bullet and go for it.

i chose this resin printer as there seemed to be a high enough amount of good reviews of people having positive experiences with it to just go for it, i dont just look at the negative reviews and walk away, i never have bought into nightmare stories being the end all of products.

the item arrived quickly as is expected with amazon products, the package contained the resin printer pre assembled (it took a few hours for me to build my ender pro, so this made me happy)

inside the box had included gloves, face masks, and coffee filters, the gloves imo was an okay touch, but no where near enough to print more then a couple of times before you will need more, the face masks are worthless and should be binned, if you are concerned about what you are breathing when resin printing then invest in a proper mask with safety rated filtration, the coffee filters are a nice touch, although like the gloves, you are going to need loads more.

as for the printer, it was in brand new condition, no “i received a clearly used product” horror stories from me!

along side this was the USB which holds the slicing program needed to form the prints you wish to use, a test print, which i always advise running first to see if you have set it all up correctly, and plenty of space for any print you would ever want to place on it.

the included instructions i had no issues following, they do lay out the steps in my opinion clearly, yes you have to use some amount of thought process of what is being asked of you, but honestly it wasnt as bad as some of the instruction manuals im sure we have all received as part of flat pack furniture.

so onto the actual printer, i guess i will start with some bad points for fairness before we move to the good parts:

1. the screen isnt super accurate, rather then tapping on the buttons you have to sort of exarate where you tap, for example the back button i have to tap in the very bottom right of the screen to use otherwise it opens up the print next to the back button

2. the screen protector doesnt actually fit the screen, like at all, its about 4mm to big in every direction leaving raised plastic in the corners (screen protector for the resin screen, not the touch screen)

3. this isnt really a negative worth being bothered by, more a note for possible future versions, the UV protection case placed over the printer can sometimes be a pain to get to sit right before it will allow you to print

now onto the good parts, the real reason why you are here:

1. the prints are amazingly high quality, i honestly havent printed anything that has any notable layering (printed at 0.03 layer height)

2. once you get the hang of how to set supports up in the software everything prints on this thing, no matter how complex or fine

3. its quiet when it runs, the loudest part of the entire assembly is the motor, and its almost reassuring to hear as you know your print is on its way

4. the vat does not require you to completely remove the screws to slide out, this might seem small, but it limits the chances of dropping the screws into the resin by ALLOT

5. COST, lets be fair, for 99% of us the cost is super important, and this to me seems like allot for your money, a 4k resin printer for this sort of money is not something you will come by every day

6. touch screen! yeah i know i have mentioned about this in the bad parts, but it is sorta cool to have lets be fair, a commodity, which has the extra touches that make it seem higher quality and as such, higher cost, without actually having the price tag attached

Now i will be the first to admit that you do have to buy allot of other stuff to make resin printing a reality, i opted for a ultrasonic bath and a UV curing booth which is not the AnyCubic brand one, i did this simply due to the cost difference, a ultra sonic bath, and a UV curing booth along side a pack of gloves, and two bottles of isopropyl alcohol (needed for cleaning the resin prints after printing) cost less then the all in one units others offer, but im still happy to report that my resin printer so far has been nothing but a pleasure, if its a reassurance to you, i also was worried when pressing buy, it seemed to good of a deal, but honestly it seems to be holding out so far!

i can not talk in regards to longevity, all screens will eventually fail on resin printers, however im hoping for years of service before this happens rather then months, if it fails to soon i will come back and make a comment updating this, but so far so good!

i also cant talk in regards to tech support, i havent had to use it, so i cant comment on it, hence why 0 out of 5 stars, i cant rate what i havent used!

happy shopping, and happy printing!

Some of the reviews for this printer are not good, various issues and problems and poor quality made me a little bit nervous of purchasing this unit. However, the offer price was good and the vouchers added made this too tempting to pass. I am very pleased that I did.

Mostly I intended to print tabletop figures for RPG and wargaming, so don’t really need a large scale printer. This is why I was looking at the smaller (cheaper) versions. The Anycubic Photon 4k has some good reviews online and in general while it has a small build scale it is more than adequate for my purposes.

I admit I ordered this with some trepidation, bad reviews may be a personal experience of that buyer, but they carry some weight when making a purchase decision. Still, I went ahead and ordered this. I figured if it really was terrible, then perhaps the Amazon returns system would protect me.

Anyway, ordering this over the Jubilee weekend meant delivery was a little longer than usual, but that’s okay, it was a fun weekend. The boxes for this and the wash and cure unit arrived – amazingly undamaged – and I put them aside for unpacking later in the day when we were less busy.

Packaging is pretty extreme for this and the wash/cure unit. Lots of foam shielding to protect the parts and several boxes containing extra parts and the power packs. So, unpack very carefully, you don’t want to leave anything behind in the packaging. Also, I would recommend you keep the boxes and packing for at least the length of the warranty. You never know if you might need it.

There’s more than a few pieces for this and the wash/cure though the main printer and wash unit are only two pieces. Base power and control and transparent yellow cover. Assembly is simple of you follow the instructions, but care must be taken. I would also recommend you wear either silk non-static gloves or a pair of surgical gloves as you don’t want finger prints on any of the surfaces. The resin tray for the printer is particularly fragile and must be handled with extreme caution. There is a thin transparent layer at the bottom of the vat which allows the LEDs to burn through and solidify the photo-sensitive resin. This is quite brittle as far as I can tell and can be easily damaged. Any damage to this can result either in poor quality prints, leaking resin or other issues. So, be really careful with this piece.

Setting the build plate and levelling is surprisingly simple. All tools you need are provided, so you don’t have to go rooting through a tool box to find things during assembly. Follow the instructions as given in the leaflets and you shouldn’t go too far wrong.

It took me about 20 minutes to assemble the printer and level the build plate. At which point the leaflet guides you through the first print. A model is provided on the included USB stick and this is fine for a test print. As it is a relatively complex wire cube with Anycubic Photon labels inside it can take several hours to print – depending on settings you choose when setting up the print.

First print for me was just about perfect. The wire cube printed perfectly, no skips, twists, ridges or breaks in the print showed that I had levelled the plate correctly. Next was the wash and cure (separate review.)

I have since run five more different print jobs through the printer (currently I’m using the Lychee Slicer, though I intend to try out Chitubox next). Each of the prints has come through clean and detailed with no print errors and no problems. I am a very happy person. Now I can print a whole bunch of the tabletop/wargaming stuff that I bought this printer for.

A variety of extras are provided by Anycubic including screen protector, scraper (to remove models from the build plate), paper face masks, hypo-allergenic surgical gloves (large), hex keys for adjusting and levelling the build plate and a plastic scraper.

It may be worthwhile investing in a magnetic build plate addition as this will save you having to remove and re-mount the build plate every time you print something. This will also help to extend the life-span of the main build plate, in my opinion.

Other than that, the only other items you may need are a container for resin left in the vat – you don’t want to leave resin in the tray for too long between prints as it may start to go off. Preferably an opaque container so uv light and other sources don’t turn the resin. As such, do not leave the printer or resin in direct sunlight.

The resin I used is the Anycubic resin, and while there is very little odour, it is still there, so make sure wherever you put this printer it is in a well ventilated area. I’m fortunate that we have quite large rooms so this is fairly easy for me to achieve. You will need to think about this carefully as you do not want to be breathing resin fumes due to close proximity or poor ventilation. I am reliably informed that the various “filters” you can buy for these and other units are mostly ineffective. The other thing that you need to remember is that the printer needs to be mounted on a firm flat and level surface.

Build quality is excellent. Overall finish for the various parts and pieces is extremely good with no rough surfaces, burrs or edges. Everything fits together snugly and performs as you would expect. I presume from the yellow colouration to the cover that there is some UV protection built in, but still take care to make sure the printer is not in direct sunlight or subject to UV light.

General print speed is good, I had four fairly complex figures go through in just over an hour. Resin usage is also good and a litre of resin will give you quite a few models, depending of course on what you are printing. A certain amount of care is required when printing models as they must have drain holes or you will end up with resin liquid sloshing around inside the model. Most good model makers providing models for printers will already have taken the necessary steps for this, but a lot of the free models that are available will not. So, be careful what you are printing. Chitubox and the paid version of Lychee both allow you to make holes in items to drain them, but care still needs to be taken.

Print quality is excellent and it is possible to print models with really fine levels of detail with this printer. As with anything, you need to think what you are intending to do before deciding to purchase a printer. This is fine for my purposes as the majority of what I intend to print is fairly small. If you are intending to print larger models, like busts or figures, you might want to think about getting a printer with a larger build plate. Many of those models can be made with this printer – provided they have been cut into pieces. But the large one piece models out there are too large for this printer, and unless you know how to cut something up in modelling software for assembly – get something larger.

Comparing this to the filament (FDM) printer I have, this is faster, cleaner and much quieter. Print quality is comparable, but to achieve what this printer can do, I’m looking at extremely fine level settings and a 0.2mm head on the FDM printer and several days to print what this can do in a couple of hours. I won’t be getting rid of my FDM printer, it still has a lot of uses, but in speed and quality, this printer beats it hands down.

Costs for running. LEDs do not run away with electricity in general, which is why changing light bulbs for LED is a good way to save money. Watching our smart meter it is considerably cheaper to run the resin printer than the FDM printer. About a quarter of the cost in electricity for the same model. However, the cost of resin is higher than PLA filament, so it all weighs out. In general considering time, materials and electricity, the resin printer is more efficient and cheaper. But, only by pennies, not pounds. The biggest benefit is that the resin printer will produce excellent results with a lot less setting up and adjusting of parameters, and faster, so in time saved the resin wins hands down. The difference here is quite surprising. Taking a relatively basic Scottish Napoleonic war soldier in 28mm, the resin printer is done in just over an hour (including set up time). The FDM printer took 20 minutes to set up the parameters and over four hours for a similar quality print. In close detail the resin print was better, though with careful painting I would suggest this difference is negligible. However, the resin printer will allow me to print a dozen figures whereas the FDM in a day will only print 3 maybe 4

Overall I’m very happy with this purchase. Once the printer is set up there is nothing more to do. Setting up models for printing is a different matter, but most models you can buy will already have supports included. Free models however do not, and this is where it will take a lot of work and time to set them up effectively so you don’t get a messed up print. I am very satisfied with the print quality and the print speed and while I won’t be ditching my FDM printer any time soon, this is definitely an addition to my toolset that will get a lot of use.

In my opinion, with a little care in setting this up, and taking your time to follow the given instructions this is an excellent entry level resin printer that will have you turning out great quality models very quickly. Perfect for the hobbyist and gamer it may struggle a bit to provide for the big scale movie fans.

As a child who never grew up, this is a wonderful addition to my toy sets and will provide hours of amusement. No regrets here. However, my wife might be rolling her eyes behind me.

edit to add photos. My wife suggested that my review might be a tad more viable if I post a couple images of the things that I have printed. The photographs are the three initial prints, the test cube, and some tabletop gaming figures.

Further edit to add:

In regards to the PFE sheet on this printer. The one provided is a plastic frame pfe sheet, which slots into the bottom of the resin vat. You cannot just buy PFE sheets for this, you must buy the actual units for this printer. These are available but you only get two. The alternative is to invest in a different plastic resin vat that fits this printer which has a metal fixing frame, this will save some money in that you will be able to use the cheaper PFE replacement sheets. Cheaper because they don’t have the sealed plastic frame attached. Now, the printer does come with instructions not to use a metal resin vat. I can understand why as there’s a good chance such an item will damage the screen – or if you have used one, the screen protector. The frame that holds the PFE sheet is slightly indented into the vat tray. This I presume is to prevent the metal screws scraping on the screen. This means, that you could use a metal frame from another vat tray to replace the one included. But, to be honest, it’s a lot less hassle to just buy a different resin vat that already has a metal frame in it.

The reason I suggest this is that the plastic framed PFE that fits this printer are difficult to find, there’s only two (as opposed to five) pieces in the pack and they are more expensive than just the sheets. If you try to replace the PFE by cracking the plastic frame open, there is a very high chance that your resin will leak all over the printer. This is not a good thing, and needs to be avoided at all costs.

I kind of get why Anycubic went with this idea, as it is easier for the end user in that you just slot in the complete frame and PFE sheet and fix it down. No messing around trying to fit a plain sheet and keep dust, fingers or other articles off it while making sure it is fitted well and tensioned well. In many ways the sealed frame is much, much easier for beginners and new users. It is just a real pain getting hold of them.

The final thing to consider here is when replacing these plastic frames they do need to be screwed down tightly to the resin tray. But, not too tight. It is a plastic frame, and if you are too heavy handed with them the plastic is likely to fracture. Again resulting in a leak.

Everything with this and probably other resin printers, requires caution and great care when doing anything.

Anyway, just a thought to go with the other stuff here.

Great printer. However for the new starter like me some tips that worked for me. I used water washable resin as it is cleaner to use but do still take care. The Lychee slicer worked best for me. Double check the settings for the resin you are using. Follow the recommendations that come with the resin. Print quality is all in the supports. Someone told me that for a new model it can take on average 5 attempts to get the supports right. The auto support function seldom works so learn how to provide manual supports.

This is my first 3D printer, so I don’t have anything to compare it to. Setup took a small amount of work, as it required a firmware update before it would print anything other than the demo file. Still, it wasn’t difficult to update, and it’s working nicely now. Thanks! 🙂

Easy set up, easy to use however WIFI setup is a little confusing and the protective yellow lid to the printer was very slightly warped (nothing a little time out of the box couldn’t fix).

Other than the above, just user experience to get the print process perfect as have builds sticking to much to the build plate.

Would highly suggest this product for those looking to get into 3D printing OR those wanting a larger build machine.

Had issues with a faulty printer at first. LCD screen was not working as it should and there was a broken cable connector.

Tech support was not of much help. and just told me to take the new printer apart and check the screen connection. in the end, i had to return the printer but it took 2 weeks to get a refund. as i needed the printer for a job i was doing i had to buy another one before i go the refund!

The second one works ok at the moment.

I have really enjoyed using this printer, I’ve had it for a few months now and the consistent quality of prints is much better than I’ve experience. Converting to a mono screen printer has opened my eyes with prints taking much shorter to finish. The build quality is amazing as expected and I love the large build volume giving me much more flexibility in what I can print. I’d definitely recommend this printer to anyone who want’s to get into resin printing or is looking for an upgrade.

Great printer with a good build plate size.

Only thing to remember is you need space above the printer to remove the cover.

bought as got sick of waiting for saturn

lovely machine, only gripe is lid should be hinged at this size

Overall I’m very happy with this purchase and it will produce many amazing prints for me! Thanks Anycubic!

I bought this printer on recommendation from a friend , I already have multiple resin printers . And this is my second larger format resin printer . This is a well built machine very robust , and quality materials used . I would highly recommend anyone to get one if you are looking to go into the larger format of resin printing .

After a few iffy test prints, I finally started to get the printer dialled in for my resin. One thing I noticed was the lack of any obvious layer lines on vertical parts. My OG Photon was fitted with an after market linear Z rail, but even that could not match the Z stability of this printer! Amazed.

The much larger build area and mono screen combine to give a far faster production speed, so print jobs that would have taken weeks, will now take days. That was the main reason that I wanted this upgrade, so I am very pleased.

The machine is also built like a tank. It has a solid metal chassis, vert sturdy linear z-rails, and just screams quality.

My only slight gripes at this early stage are that the firmware is still a bit buggy (which I’m sure will be sorted), the screen, while mono, appears to have a plastic top face, which is a definite downgrade from the glass in the OG Photon. Also, my preferred slicer is Chitubox, which is not currently compatible at time of writing this review. Still, I can add supports in Chitu, then export the supported STL to the Photon Workshop for final slicing. No big issue.

If you are looking to upgrade a smaller, non-mono printer, then I would highly recommend the Mono X. If however you are looking for a first printer, you could try one of the more forgiving and lower cost ones first to ensure the workflow is for you – you can always add a Mono X when you get the printing bug!

The printer arrives very well packaged from amazon double boxed for protection and weighs 14KG, care

will need to be taken when moving it.

Inside the box you will find a fully assembled printer that just needs to have the build plate added.

You will see the instructions on how to do the initial levelling of the build plate, just follow the instructions

and you can’t go wrong.

The printer is a very good-looking machine and certainly does not look “cheap” it is very well constructed

and looks fantastic alongside my other printers.

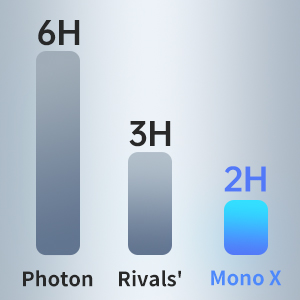

Print time is fantastic and depending what resin you are using you are looking at between 1.5-2.5

seconds per layer compared to the Anycubic Photon S which is around 8-10 seconds per layer.

If this is your first resin printer i would suggest you do a read up on the printing process as you will need

to buy some extra bits for cleaning up your prints.

Isopropyl alcohol

paper towels

UV Curing light

Gloves

These are just a few bits you will require

You are provided a few pairs of gloves, face masks and some resin filters but only a small quantity so i

suggest you stock up on them.

I have posted some images of my setup and some images of prints I have done using the Anycubic

Photon Mono X, i highly recommend this printer and I am sure you will not be disappointed.

Don’t hesitate to ask questions and i will try to answer if i ca

Setting up the Photon was simple, following instructions which are clear and concise; the only assembly required is the door knob, and all the required core tools and accessories come with it. There is a learning curve to getting the machine functioning properly — which can seem intimidating — but once the basic steps are put in place, you’ll have amazing prints time after time. With some testing you can rapidly get how to set up your models to print optimally, in terms of time, quality and resin use.

To start with, environment. Temperature seems critical. The warmer the better. My first error was placing the Photon in a heavily ventilated but very cold utility room: I just couldn’t get any prints to work when I first received the machine at the beginning of the year, and parked it during a busy period. With the last month’s enforced isolation coinciding with unseasonably warmer weather in the UK, I relocated and haven’t looked back. Secondarily, obviously a stable and level surface. Have windows open: I haven’t experienced particularly bad odours, but it’s just safer — and nicer for anyone else in the house!

Next, set-up. Levelling the build plate is where a lot of people seem to go wrong, but having checked out many online guides the one that works every time is this:

1: Put a sheet of paper over the screen.

2: Lower the build plate in 10mm increments so it’s close to the screen, before switching to 1mm to bring it within a couple of mm. Switch to 0.1 and bring the plate down in increments, sliding the paper in and out until you can’t slide the paper back without it crinkling.

3: The crucial added part: lightly hold the build plate evenly with one hand and tighten the screw with the other. Then raise the plate by a couple of mm and repeat the process.

4: Back out of the menu system and hit the Z=0 button to set the correct minimum level height. Retract the plate in 10mm increments so you can get printing.

Tightening the plate can sometimes make it retract a fraction, which is why you have to repeat the levelling process again. Don’t miss this step! There are plenty of online videos to help show you the process. It takes seconds, and saves wasted hours and resin.

Prints: PPE appropriate to our current situation is necessary. Gloves and a mask to be safe. Shake your resin well, then pour into the vat. Select your print from a USB stick and you’re good to go. The results are just great, which takes us to the next learning step: slicing and structures.

The included software is fine, although Chitubox is a popular alternative. They all work the same way, and don’t require overt software knowledge to use. Import your STL file and orient it on the print bed for optimum printing. Simpler objects (walls, accessories) can print ‘normally’, level with the print bed. Figures, which the Photon excels at, can be typically orientated at 45 to avoid overt build lines being visible at lower print resolutions, but it’s not always necessary.

However, I would always use a support structure with raft, no matter what, and that’s where some trial and error comes in: there is no ‘right’ answer to that, as it depends on the model. Start using the automatic support structure functions to learn what does and doesn’t work (which will likely be the former for a lot of things). Then start building your own supports, which is as simple as selecting the type (light, which have tiny contact points ideal for figures, medium or heavy) and clicking where you want the contact point. Again, there are lots of guides for settings to use, but common sense works here, and Chitubox in particular highlights weak areas in red.

If you print any larger objects then use the auto-hollowing tool (in Chitubox) and slice with infill turned on. It will turn a massive lump of money-wasting resin into a strong, light and efficient print. Slicing is another easy part, where the software does the heavy lifting; you just need to remember to use the settings correct for your resin type and model (does it need infill, basically). There’s a great online spreadsheet for resin settings available on the Anycubic Photon Reddit channel and also the Facebook group

So, I couldn’t be happier with my Photon. My house is quickly filling up with an insane amount of prints, as the unstoppable excitement of ‘what can I print next’ takes over! Learn the process, experiment and expect some mistakes, follow the correct steps each time and you will see this printer shine. I’ve stuck at 0.05mm resolution, and I’ve never been disappointed, but the printer can print at double that res for even more detail (at the cost of print time). It’s just an excellent tool that opens up a world of possibilities.

This is a great starter 3D printer. Its great value for money and easy to use. There are online tutorials for those who may struggle. The quality is fantastic, no lines and perfect for small models for example D&D. I am looking at upgrading to a larger printer as the build plate on the Photon is small but like i said perfect for small models. Software for supporting and slicing is also provided with the printer.

I was a little reluctant to buy this 3D printer as I knew there was a learning curve to 3D printing in resin and I’d never owned a 3D printer before. Decided to take the plunge – there was a few failed prints and a learning curve but these were all my own fault. Once I got the knack of levelling the print bed and ensuring my models were properly supported I’m now able to crank out pretty neat models that I’ve made in Oculus medium or from Thingiverse. Really satisified with it!

This is my first time with a resin printer, the ease of use has made experience a joy, yes there has been a learning curve ensuring you wear gloves, cleaning the print, getting supports right and and curing the finished print. (not much sun in the UK at the moment) so a way of curing needs to be sourced

Ensuring you level the bed, plenty of advise for that on-line

The photon community and forums makes the use of the printer a pleasure.

I think this is a great and not too expensive introduction into the resin community, especially if you get it on a sale

I’ve had the AnyCubic Photon for around 3 months now and had owner an FDM printer for several months before purchasing it and despite that the learning curve with the Photon was pretty brutal.

The first issue I had was that the files on the USB that came with the printer were corrupted. This meant that I had to jump in blind. I had three weeks of prints sticking to the bottom of the vat, thinking the issue was the printer before finding that the problem was the exposure settings I’d googled were twice what they should have been. After some successful prints I had issues with getting cured resin sticking to the models randomly, turns out the previous fails had damaged to FEP.

After changing the FEP, I had issues regarding prints not sticking to the build plate and then eventually getting semi-cured resin on the FEP. After some help, it turned out that the issue was the ambient temperature in the room (it had been too low) and the FEP loosening from the fails.

Now, after all that, I’m in the zone. For the past three weeks I’ve churned out almost a hundred high quality prints, on par with, and sometimes better than store bought miniatures. Using 3D builder I’m able to combine and customise models in ways that would be impossible with traditional kits and the cost is minimal. It is great, I love this hobby, printing anything I want to is incredible.

Basically, don’t get disheartened, speak to people with more experience, change one thing at a time and persevere. The Photon owners group on Facebook has been a huge help.

If you’re on the fence about getting a resin printer; just do it, you won’t regret it.

I bought the printer to mainly print wargaming vehicles that are difficult to get hold of from traditional sources. E.g. the Austen “Tilly”, a British light utility truck made in the 10s of thousands but is impossible to get in 1/100 scale.

For this purpose it has greatly surpassed my expectations, with the prints being accurate and crisp and in many respects better than some manufacturers. Some print lines can be seen but most of these are shallow enough to be hidden by the normal painting process. Only on near horizontal surfaces (e.g. the bonnet of the above “Tilly”) have I had to do some slight sanding. The quality was such that I have also printed several 28mm Sci-Fi figures.

Setup was simple, with easy to read instructions on how to level the print bed which is pretty much all there is to it.

The bundled software is also simple to use (there is an updated version on the website but I actually prefer the older version on the USB drive) and after a bit of practice it takes very little time to prepare a model for printing. My 10yo son did a homework of making a spaceship from scratch using online 3D modelling software with very little help, I just did the handling of uncured and partially cured resin for safety.

Not everything was plain sailing, however. I bought the printer without knowing anything about printing with resin so was ill equipped to deal with the whole process. As well as the printer you will need some cleaning alcohol (99% pure IPA) and a suitable container to wash each print, a box of nitrile gloves and a method of fully curing the prints (I bought a strip of UV LEDs and made a curing oven from a plastic box and aluminium foil).

I also had a few early print failures; I wanted to use the printer in my garage workshop and as the lowest working temperature was stated as 10C I thought this would be fine, but the prints just wouldn’t stick to the print bed. As soon as I brought the printer into the house it’s been nearly flawless.

So I’m very happy with the printer and it has already more than paid for itself compared to getting items printed commercially. I just need to get around to painting all of the stuff I’ve printed!

If you’ve been considering it but have been put off by the resin mess, that’s fair. But from my experience (and I’ve been printing on this thing for 6 months now) the mess is minimal as long as you’re sensible. And the practically invisible layer lines means you make up the time by not having to sand it down as much.

The main thing you may want to think about is whether the print bed is large enough for what you need. Though, the images I’ve provided were all printed on the Anycubic Photon so you can get large prints if your crafty about it. I am a character sculptor and so can factor the print bed size into the design of the characters I make.

So if you have the money and you need amazing quality prints, get it now. You won’t regret it.

I’ve had my photon for a couple of months now so think i can offer some insights.

First off, you can’t just open the box and start making things. You need to do some research. Fortunately the community is excellent. Use the “flint reed” method to level your prints and the community spreadsheet for settings and you’re good to go. I’ve had no failed prints since i’ve done that.

I’ve printed miniatures for our current PF2 pc party, I’ve printed objects for set pieces …dungeon furniture. Its lovely. Now i want a bigger printer

Strongly recommend.

I’ve been using the Photon to print custom miniatures I create in ZBrush.

It’s not been a completely stress-free time, but the issues were 99% my fault.

There was a lot of trial and error and failed prints, but that was to do with my print/support settings.

There’s plenty of websites out there that help with this kind of thing now.

Overall I’m extremely pleased with the printer and also Anycubic themselves. I had an issue with the screen and they were more than happy to send me a replacement.

If you’re on the fence, go for it. It’s a great feeling seeing a print come into existence, especially if you’ve created it yourself!

The printer arrived well packaged and after following the instructions included was able to print the test piece within an hour. It might take a couple of tries to get the levelling height, but that’s the nature of 3D printers that lack an autolevelling probe. Once it was levelled, I have been able to print many intricate models that a traditional 3D printer would not be able to do.

Be warned, due to the level of detail this printer achieves, prints do take a very long time, even smaller ones. Overall I would recommend this to anyone with a bit of experience with 3D printing that doesn’t mind getting their hands dirty with resin printing and is looking to make some very intricately detailed parts or models.

This is a great printer – good quality prints and easy to use, well worth the price.

Like any 3d printer, there is a learning curve to using a Anycubic Photon, but honestly, I actually have fewer problems with it than I do my inkjet (2d) printer, let alone my filament printers. I’ll try to distill some of what I’ve learned over the last 6 months in this review…

Overall, the quality of the resin prints are fantastic – I usually print at 100um layer heights which I find to be perfectly acceptable for my purposes (miniatures for dungeons and dragons). Layer lines are occasionally visible but only if you look very closely, and would be even less visible if I printed at a lower resolution.

The only print failures I have had with the Photon were when I had not properly levelled the bed, but it’s easy to do on this printer. I now routinely do so before starting a print by 1) removing the resin vat, 2) homing the (alcohol cleaned) build plate, 3) inserting a regular piece of printer paper between the build plate and the screen, 4) lowering the build plate in 0.1mm increments until I can pull the piece of paper out towards me but cannot feed it back into the gap (usually 0.2-0.3mm lower than the home position on my printer, ymmv). If either side feels looser than the other it’s time to readjust the ball joint too, but it is usually months between these instances.

I use Chitubox as my slicer, and I always run the .photon files through the photon file validator by photonsters (available on github). This ensures there are no ‘islands’ of resin not connected to the main model that just get stuck on the FEP. I have been through 1500ml of resin so far (all anycubic transparent green), have yet to change my FEP, and it is still printing reliably because of the relative lack of failures and lack of damage to the film.

I recommend getting an ultrasonic cleaner and fill it with isopropyl alcohol for cleaning of prints when they come out of the printer. This allows you to see much finer details that would otherwise be clogged with the viscous uncured resin from the vat that clings to it. Always use gloves and a respirator when handling the uncured resin and alcohol and finish curing the models after cleaning them either in direct sunlight or under a uv lamp.

This is a great entry level resin printer, with a ton of community support on the internet as it’s such a common and popular model. For example, there is a community collated spreadsheet of resin settings for this printer (google “anycubic photon spreadsheet”), which is hugely valuable for giving you a decent starting point for experimentation with exposure times, as well as the aforementioned file validator. I highly recommend it for anyone looking for better detail on their prints than a filament printer can provide, or wanting to produce many identical but small items at once.

Pros:

-As stated in the title, Great and high-resolution print quality

-Easy to set up if all safety precautions are taken

-Extracting prints is very easy

-Easy to navigate menu

-Very nice looking and the door for the printer is quite neat for reducing the risk of spilling resin on the work surface

-Basin plastic sheet very durable, Haven’t had to use replacements

-Very easy to select prints

Cons:

-Build plate can get loose at random, Sometimes it will be fine after 5 prints, other times it goes loose after 1

-Can be quite pricey compared to the competition

-No other cons really

Suggestions:

-Add a dripper handle to allow for build blate to be on its side and drip back any residue resin

-Provide a few more gloves for people who might not have immediate access to nitrile gloves

-Allow connection via wifi

Tl;DR

Overall great printer for its price point, perfect for anyone interested in resin printing and trying to get started

I am using my Photon for printing scale model parts, particularly rc model boat fittings. I just love it. I can get sub-millimeter detail that prints cleanly and accurately. It has totally changed how I go about modelling and the results are very good indeed. In fact I can get better results with the Photon than I can buying commercial model fittings. I can print really complex shapes such as model propellers and they print with no seam lines, unlike molded fittings. The only slight issue is in leveling the print bed. That involves a fair bit of trial and error. In a future model of the printer I would like to see a fixed permanently level print bed that is factory calibrated. However that is a minor issue and I have no regrets on my purchase.

I have had an FDM 3D printer for a couple of years, used mostly to print terrain for RPGs etc. Always quit fancied being able to print my own miniatures. Picked up the Anycubic Photon as it came recommended on the miniature groups I follow on Facebook. Blown away by the results so far! Attached are some photos of minis printed on it, from Cast N Play Patreon.

Set up was straight forward. Had to repeat the bed levelling a couple of times as I wasn’t quite getting it right, but since I got it bang on, I haven’t had to level it again for easily 20 prints! 🙂 Would recommend this for anyone looking to give resin printing a try.

I purchased this printer to produce parts for my model boats. This printer is very easy to set up and if you need there are loads off “you tube” videos to help you. The print quality I’ve been getting is outstanding. You will need a uv lamp to cure your prints. I use a uv gel nail lamp. The items you can make with this machine is limitless.

If you are thinking about getting one don’t wait get order one now

Having purchased the Anycubic Photon as an absolute newbie to 3D printing I was incredibly surprised at how easily I got everything going out of the box.

My intentions were to mostly print terrain for Warhammer 40k, as well as experement with some 3d modelling myself. However, after a couple of prints I was amazed at the detail and quality of the prints considering the price!

If you’re purchasing one yourself make sure to watch loads of videos to educate yourself about how to get things set up correctly.

I would also recommend printing the test cube that comes bundled on the USB stick to ensure your next prints will turn out as well. Once you’ve got the test print perfect hop onto Thingiverse or get some STL files elsewhere and get printing!!!

This was my first 3d printer and all I can say is wow amazing.

The quality is amazing on the prints and the machine is built very well too. Once you have done the correct initial level of the build plate then you shouldn’t have any problems with prints. I have printed about 30 prints so far and each one has been perfect. I have even moved the machine from my workplace to home a few times and never had to re-level.

If your looking for a good 3d resin printer then this one is a must. Easy to set up and even easier to print!

As an owner of many 3D Printers.

Both FDM & DLP

The ease of use and level of quailty control that went into the photon is beyond a amazing.

Super simple to level, Super simple to print.

You get a bottle of resin included which is enough for many prints. I’d highly recommend running the test file as a guide. Just to make sure you’ve level probably. By far one of the best printers I have used.

So my printer arrived dead on arrival, the LCD screen was not functioning.

Anycubic support team me through the basic trouble shooting and confirmed the dead screen, so sent out a replacement part I could fit.

Once done, I was up and printing and like other users was blown away by the print quality.

Love the printer, fantastic purchase!

I’ve had this printer for almost a year now and have been 3d printing for about 4 years now with FDM printers (5 printers). This thing is a totally different beast from the FDM printers, it’s quiet, doesn’t need any tinkering to make it work. I’ve leveled the build plate only once and never had to do it again (try that with an ender 3 or a cr-10!). The small print bed and high detail of this printer puts it in a different usage bracket obviously.

So far any issues I’ve had with prints not completing have been due to my own errors in preparing the 3d files, either not having enough supports or supports that were optimistically thin. But overall my success rate has been very high.

Everything I’ve printed has always been my own models, they invariably come out looking super detailed, whether it is small mechanical details or more organic shapes.

My fdm printers are feeling very sorry for themselves, hardly being used now except for my very large format cr10-s5.

I’ve been using this printer for around 5 months now.

Being new to 3d printing in general, it took me a couple of weeks to get up to speed and overcome some of the common issues.

Now I’ve been using it for a while, I can’t be happier. I rarely get failed prints and, if I do, I’m confident it’s my fault due to my settings/supports etc.

I mainly use the printer for miniatures, but I’ve also printed lithographs, ornaments etc and it works well for all of these.

I’d definitely recommend joining some anycubic photon groups on social media as it’ll get you around any troubleshooting issues quickly.

I already used an AnyCubic I3 Mega filament printer, so chose the Photon UV printer as I had not had any problems with my previous Anycubic Machine. I have had the Photon now since mid July this year add have enjoyed using it. I was looking for something to print more details than I can obtain with my filament printer and I am more than happy with the results I can achieve with the printer. As I 3D model for a living , I can now produce what ever I want for my Hobby by combing the printing abilities from my Filament printer and the extra detail parts of the Photon I can now produce .The image of the two post boxes show the difference between a Filament printed version and the Resin printed version of the same model.

The world of 3D printing is massive, consuming, but ultimately rewarding.

Firstly a disclaimer – if you are thinking of getting this for kids – don’t. You will want a FDM printer instead, the one that prints off a spool. The materials involved in resin printing are toxic, smelly, sticky, and in no way suitable for kids.

If, however, you have somewhere decent to put it – this little printer will get you some absolutely fantastic results.

The initial setup was easy enough following the instructions, and once the bed is levelled (see the flint reed method on YouTube) you will be away.

There are infinite worlds of tweaking to be done – including custom firmware, custom slicer tools, different post processing methods… But the one thing is for sure is that the AnyCubic is accurate and reliable once configured properly.

What a great little printer! I got this to print toy prototypes. It is really simple to use, once you’ve leveled the bed. Which is easy enough to do just remember to tighten the grub screw very tight! Or else the bed will shift during printing. The build quailty is solid as the photon has a metal body.

I do have some z wobble but I am yet to fix it as its not that bad. But I’ve seen that it’s easy enough to fix with some grub screws on the carriage. I’ve been using the prusa slicer to add supports and then chitubox to slice the model ready for printing.

I have been using anycubic green translucent resin and so far I have been very pleased with it. Print time for my alien was nearly 10 hours. It’s so fast and the quality is so much better than an fdm machine. I am very pleased with it so far.

This is such an easy printer to use. There is very little set up and build plate tramming is a breeze.

I also have an FDM printer and slicing (using ChituBox) for the Photon is far simpler, with way fewer parameters to consider.

Post print cleaning of prints is necessary but nowhere near as bad as people make out IMHO. If you have ever used spray paint then I’d say the spell is no worse, with the strongest spell being from the IPA used for cleaning rather than the resin. There is a slight smell given off during printing but I’ve hardly noticed it.

The quality of the prints is fantastic and perfect for printing miniatures which is what I mainly use this printer for.

Update Feb 2020.

Printer still going strong and I’ve been a good amount of resin printing miniatures and scenery for wargames. The quality still amazes me and once painted you cannot tell the printed miniatures from the plastic injection moulded ones (so long as you get good 3d models t begin with).

Seriously considering more of these (yeah I know the Photon S is available but the plastic body puts me off) for my business to print items for sale.

I have been using my Anycubic Photon for just over 3 months now and am extremely happy with the results I am receiving.

Out of the box and with very little setup (levelling the build plate) the sample model of a lattice cube printed well using the supplied green transparent resin, with only a couple of tiny air bubbles in the base. These bubbles were probably due to my shaking of the resin prior to use and not allowing the bubbles to clear before I started the print.

I have printed a number of tabletop gaming miniatures with this printer and am very satisfied with the quality — no visible layer lines and precise detail.

When printing items which require a mechanical fit (e.g. one tube sliding inside another) some experimentation with clearances in the model is required. My understanding is that due to the process of using a UV light with an LCD mask outer dimensions may be slightly enlarged, and inner dimensions may be slightly reduced due to “light bleed”. This is a function of the printing technology and would be seen on all printers of this style, it is not the fault of the Anycubic Photon.

The Anycubic Grey and transparent green resins that I have used are more brittle than FDM printed materials (e.g.PETG or PLA) but meet my requirements.

The clean-up process with resin printers is reasonably time consuming and does require personal protection items (rubber gloves and safety glasses as a minimum) and cleaning items as follows: lots of paper towels, Isopropyl Alcohol for cleaning resin and 2 plastic sealed containers for cleaning the models in IPA. Due to the smell of the resin and IPA, and the potential for resin spills I have my printer set up in my garage rather than the house with my other printers.

At this point I have only re-levelled the print bed about 5 times and these were only because I carried out a full stripdown for cleaning. I have not changed the FEP sheet yet and cannot comment on how easy or hard this is.

Having used FDM printers for about 10 years I must point out that there are several differences required in model orientation and support for printing between FDM printers and the Anycubic Photon. I would strongly suggest viewing the videos of YouTuber 3DPrintingPro which helped greatly with my initial setup attempts.

Overall I am very happy with the models produced by my printer and would recommend it to others.

After a slight learning curve with how to support STL files properly so there are no overhanging parts of the print, every one of my prints has been pretty much perfect. So impressed by this little printer. I’ve used Anycubic Green, Skin, Grey and the new plant based Macaroon Blue… all have been excellent for miniatures. Honestly…it is mind-blowing how much detail you can get out of this printer. Tiny modified hands and weapons for my 28mm Warhammer guys…some no more than a few mm in size, yet all the detail is still there.

Highly recommended.

**** UPDATE December 2019 **** I have just ordered and had delivered a second one of these in the black Friday specials as I am so happy with this 3D printer… The problem is, when I get a chance to play with my hobby of 3D printing, it obviously takes time to print something, and often I want to get more than one print running… But with the cheap cost of this printer, now I can set two prints rolling, come back later to see the fruits of my imagination!

**** End of update ****

I have been 3D printing for about two years now, originally using a Creality Ender 3 (which is a molton plastic or FDM machine), but found that there are drawbacks to FDM printing, which is that obviously the plastic you are printing is designed to melt, which means your final print can melt. Not a problem for most people, but I am an engineer who designs parts for cars. So I needed something which could print parts which hold up to heat in engine bays and inside cars on sunny days. which resin printing (what this printer does) is perfect, as it withstands higher temperatures, but also produces more detailed or smooth items and in many ways the printed parts are stronger.

So I bought the Anycubic Photon after many weeks researching and using many other machines owned by other engineers, and to be honest I am so pleased I chose the Anycubic Photon!

The build quality of this is great, it is housed in a metal case (not flimsy plastic like some) so it will take knocks in it’s stride.

The product, although so similar to many other resin printers on the market, actually has many improvements over many. You can spend much more money and get one which will print faster, but what people do not seem to realise is that the faster printers make less accurate and weaker prints, as a chemical side effect of them using higher power light sources, which makes the resin crystalise in a weaker orientation than a machine like the Photon (meaning this machine might be slower than some, but it produces stronger and more detailed parts as a result!)

I have had this machine now for three and a half months, and my experience of it just gets better the longer I have it, and the more I learn.

I would also like to commend Anycubic on their customer service. I have not really needed them as the machine worked great just out of the box, but when I did once need their help, Jessi at Anycubic helped me quickly and precisely (in perfect English) and had me up and running again in no time at all.

Anycubic also have self help videos on Youtube should you need any video instructions, or need to troubleshoot a problem, but even without any of this, on Facebook, there is a group for this printer which has a community of thousands of members all helping one another to learn about the printer, to support each other, and to share their progress on their 3D printing journey.

Anyway, I really can’t say enough good things about this printer and Anycubic.

I will go on to say that I have experimented with several brands of Resin with my machine, and can honestly say that the Anycubic resin is as good as every other brand I have tried, if not better… I would go further by saying some of the brands I have tried (well known brands) for resin have been more problematic to use than the Anycubic ones, and in the market, the Anycubic resins to to be priced at a really reasonable price (you might save a couple of pounds shopping around, but the resins bellow this price are really not as good)

Anyway, stop procrastinating and buy this printer now! You will not regret it.

The anycubic photon is my first SLA based 3D printer having had some experience with FDM printers in the past. The setup is very simple, bed leveling took less than 5 minutes and initial prints made came out great.

Been running it none stop for the past 6 weeks and have no major issues at all. Would advise to purchase an air purifier unit though to limit the smell of the resin.

Overall very happy with purchase, great community support. Is an ideal printer someone wishing to start into 3D printing.

I started printing with an Ender3 which is great if a little lacking in detailed prints. So I bought the Anycubic Photon, it really is fantastic, I’ve been printing and painting minis in my spare time ever since I bought it. The quality is amazing and really once its setup and working there’s not much else to do. I only ever re-level the build plate if I get a failure, which is very rare. The reservoir gets cleaned out about once a month, or if the resin that’s being left in there between prints, and topped up, gets gloopy. I highly recommend for all D&D GM’s or anyone with an interest in models.

This is my first ever resin printer and i was amazed be the quality of the initial test print and also how simple it was to set up, I have a PrusaMK2 FDM printer so i was familiar with 3d printing before i bought this product and i had done alot of research into the setup of the machine and also safety and cleaning, you can find great videos on youtube about these subjects and i would recomend people look up some info before buying this printer so you are aware of what needs to be done because if you prepare properly then this printer will be very simple to setup and use with minimal effort.

I setup my machine and leveled the print platform once when i first bought it and never had to do it again, the printed have been perfect every time although i have had a couple of small issues but they were down to my own fault of not preparing the moel properly.

For the price you are paying the quality is fantastic, I use this more then my Prusa now although i stll use the Prusa for larger parts.

I highly recommend this printer but just make sure to do some research first as there are safety issues using resin that require you to use gloves and keep the work area clean. 🙂

It’s great that this runs with a USB mass storage device – it means I can operate it from arbitrary sources of data and have a lot more fun. The print quality and easy of use is truly amazing – in a really good way.

The software that comes with it is a bit rubbish so you have to find other software – they recommend getting an account with a 3rd party. This is why there’s 4 stars instead of 5. They tried to help me get the 3rd party software without an account but that was unsuccessful unfortunately.

Their support people are really helpful, open and honest which puts them at the top of my list of good companies and this device at the top of my list of recommendations.

FANTASTIC! That is the only word to sum up this product.

We have been using the ANYCUBIC Photon UV Photocuring 3D Printer, Ultra Precision 2560×1440 2K HD Masking LCD with Smart Touch for 4 months now with a 100% pass rate for all the teeth that have been prepped. Traditionally, we were using wax to give a impression of the prep surface, contours and fit but with less of a success rate.

IF I HAD KNOWN THAT CHINA HAD SUCH A MACHINE I WOULD HAVE PURCHASED IT A LOT SOONER!

TOP TIP: Read the instructions and have a few experimental attempts first. There is a knack to using it so do not be put off by the first monstrosities that YOU produce, it is not the printer, it is the user. Practice makes perfect for sure.

This is my first resin printer, I have over 2 years of experience with PLA printers.

As with any printer there is learning curve – here things are much more complicated than with PLA printers.

The whole process is more messy, it is more smelly (if it matters to you you can easily install a fan or a proper filter), it takes some time to get things right bot once you do the results are just breathtaking. You can’t even remotely compare PLA prints to the resin ones.

The printer itself is high quality – they didn’t cut any corners. I use it mainly for wargaming so quality of prints is my priority 1. Any failures with my prints so far were only my fault (model support mistakes). I’ve not had a single problem with the printer at all so far. Within the time you may start to modifying it – e.g. like mentioned ventilation fan. There are plenty of suggestions online.

The only thing you should keep in mind is that this is not like your normal paper printer – this is a hobby and it requires a lot of time and research to do things right. Don’t take me wrong – you can use it out of the box and print provided examples, but after that you will need to learn by yourself how to print things downloaded from the Internet. Luckily there are many youtube tutorials and great facebook page.

If you’re not afraid of the learning curve (and this will apply to any resin printer), if you’re fine with investing your time to learn that hobby, then I really recommend that printer.

Talking about bad things or not as good as I would like to (Photon, not Photon S): no ‘turn off after printing’ option, small ventilation fan with a filter is not doing the job at all (disconnect it right away), the ball-type plate mounting is not great but you can print a great 4-screw mount, USB stick – bin it, sooner or later you will have Z-axis issue – you would need to adjust it every now and then or upgrade to dual axis. It sounds like a lot but trust me those are little things only. Also keep in mind that LCD screen is consumable like in any resin printer – expect to replace it every 6 months with 24/7 printing.

Overall – it is an outstanding piece of equipment.

After thinking about it for a while I finally decided to bite the bullet and order a Photon around 4 months ago. I’m a scale modeller so the fine detail of resin printing over more traditional methods was a no brainer and the Photon came out as best bang for buck.

If you read around forums and Facebook groups there’s plenty of horror stories of these things being a nightmare to set up and use but honestly even as a complete newcomer to 3d printing it was an absolute breeze. Most issues people have stem from incorrect levelling/the build plate being too close or too far from the screen at the bottom (sometimes 0.1-0.2mm can make the difference between the print sticking or failing) but I managed to get mine bang on first time using the paper levelling method, and once set up you hardly ever have to relevel. Most other issues are commonly either insufficient supports or incorrect resin parameters. Both of these really come down to practice and a bit of trial and error. In 4 months I’ve had maybe 3 properly failed prints, 2 of which were insufficient supports, 1 was the build plate being too far from the bottom of the vat, the rest of my prints have been pretty much perfect.

They are inherently a bit messy to use due to the cleaning process but just have a good supply of disposable gloves and paper towel to hand and it’s no big issue. The smell is very much down to personal sensitivity, when I first bought the printer and used the included green resin the smell seemed incredibly strong, however you do get used to it, and some resins smell far less. I mostly use Elegoo Grey for model components and the smell is almost non-existent. There’s no need to empty and clean the vat after every print, unless your last print failed and stuck to the bottom. I’ve left a full vat of resin in the printer for weeks and after a quick stir it’s ready for printing again.

After 4 months of regular printing (perhaps 3-4 prints per week), I’ve still had no need to replace my FEP, despite it being fairly scratched and cloudy, nor does my screen show any signs of failing. Both of these are apparently easy, quick and cheap replacements though and can both be classed as consumables. One thing I would highly recommend is placing a strip of thin Kapton tape around the edges of the screen so in the event of a resin leak or spillage, the resin can’t get into the inner workings of the printer and should be much easier to clean up.

If you’re on the fence, I’d highly recommend taking the plunge, this printer has literally opened up an entire new world of possibilities as a modeller. The detail achievable is just stunning.

The machine is built quite well which is the reason why I bought this old model rather than new plastic one. The first print did not work, due the screws on the vat being too loose. Then got few fails due the wrong settings in the default program, so I adjusted settings to the ones on reddit. The exposition time for green resin have to be longer as it does not transmit light as good as the transparent resins. So when I got that figure out I managed to get some prints done but they get usually strached od deformed if they have flat surfaces, so to accomodate for that, you have to angle the object on 45 degrees more or less, and add more supports, and make the model hollow so it does not pull itself off the supports. remmember internal supports are nescessary too.

The calibration of this device is quite important and you have to really get it right otherwise it wont work at all.

The smell is not that bad I I attached a fan a duct and a carbon filter on the end to remove any residues.

The vat is not heated so beware of printing in the winter you have to keep the resin heated to at least 25-30 degrees.

The machine would be silent and nice if the fan on the bottom would not be that loud (to cool uvLED array).

Important you cannot work with this printer in the room that has window and sun, as it will cure resin of course, so keep that in mind.

The level of detail due the 4k display is great, the downside is that you will have to replace it one day because its a consumable so buy a spare one when they still make them.

The slicer (chitubox) is ok but for some reason I still have dimensional innacurate prints so there is no use for engineering parts that would fit into each other. But its ok for figurines and models .

Its higher detail than fdm, but its more messy process, takes more time to cure, and you have to varnish or paint the models, or if expose to sunlight will turn yellow, so make sure you paint them.

I have got a photon as a cheep replacement to handle prints when my more expensive resin printer had a fault and was waiting on parts, only to start using it more and more as it was faster than the Moai I use due to the difference in technology. During a screen replacement I pulled a connector off the front screen, within a week of contacting support I had a spare screen and was back up and running, with no charge. This was something I was not expecting for a cheap printer I got as an emergency to keep printing and customers happy. Would recommend this to anyone looking at MSLA printing, however please remember that this is not printing with PLA, its messy, the resin is harmful and should be put in a garage or other place outside the home. The screens will need to be replaced regularly, and consumables will cost a few pennies, please read about SLA/MSLA/DLP printing before buying as to know what you are getting into.

I had been on the edge of buying into the 3D printing hobby for a couple of years, but hearing some of my friends experiences of messing around and constantly having to fine tune and adjust their machines, I was put off. Not to mention the higher costs a couple of years ago, I wasn’t going to drop my money into a pit.

However – I am so glad I bought this Photon! It is an extraordinary machine for the low price! Very high print quality with smooth finish, even at 0.05mm layers. The slicing software feels somewhat basic in comparison to others, but it does the job. However I would recommend the ChiTu box software for hollowing/creating supports.

Overall, I am more than happy with my Photon and would highly recommend it to anyone thinking of getting a resin printer.

This printer is great as an entry level to 3D printing; the print quality is great considering the price. Although it may not be as detailed as SLA printing machines (which are relatively more expensive), the Photon’s DLP is still great for highly detailed models that require little work other than removing the support structures and a bit of sanding. This printer is perfect for printing small detailed models and has a large enough build plate to print separate parts to piece together for a larger model. There is quite a learning curve with the process of printing with using the machine and the software but once you have the hang of it, its as easy as slicing your models and running your prints.

The only issue I have with the overall experience is the slicing software, which feels quite limited and could have some work done on it. From experience, it doesn’t seems to import my 3D models to the true scale that they were exported as.

Bought for 260, delivered by Amazon prime.

I love this printer. I’m not new to 3D printing. I’ve used and abused a Creality CR-10 for some time- it’s so heavily modified now it’s something else entirely. I used to use a friend’s DaVinci 1.0 AIO, and I’ve spent longer than I should on my local hacklab’s delta machine. I’m happy to report this is nothing like any FFF printer I’ve ever used.

Why? Because it just bloody works. You slice the stl, put it on a USB stick, and you hit play. You don’t have to check on it every fifteen minutes to make sure it’s not reverted to a spaghetti gun, you don’t have to worry the bridges are going to come out saggy or the nozzle’s going to block. You just wait for it to beep and wash your model off. The detail and precision you can achieve is astounding, particularly when you compare it side by side to FFF. I’ve had success printing tiny mechanical parts, and gears I designed with 0.7 module worked first time.

It’s not zero setup, but it’s pretty minimal. It comes assembled, and it’s a nice set-contained unit that’s surprisingly small. You just need to level the bed and run the test print. Between parts you need to check the FEP is clear before your next print, which I do by using the plastic spatula. Post-processing requires washing the parts in IPA to clear off the unused resin, which I suggest is best done using a series (two or three) of IPA baths (pickle jars) in a constant sequence. Then you leave them in the sun to harden properly.

It’s not perfect, and sometimes parts’ll get stuck to the FEP or come loose from the bed, but it’s much less fiddly to make the process work than FFF. Most problems I’ve had related to exposure times (if it’s too short your parts won’t stick to the supports properly), or model and support placement. But it’s surprisingly forgiving, and at least when it fails the bits stuck on the FEP stop any further plastic being deposited on the broken areas so you don’t waste anything but time.

The one thing that put me off resin printers for a long time (well, apart from the cost) is the resin. It’s not benign stuff, and it’s expensive. But anycubic’s resin is only about 40/kg, and while that’s about twice the price of FFF plastic, it’s not a huge problem particularly considering that these machines really excel at printing small parts rather than furniture. With regards to chemical safety, you should never let the uncured resin contact your skin (it’s an irritant and a sensitiser), and it can apparently smell a bit although I’m not sure about the health effects of the fumes. I haven’t noticed much smell from Anycubic Green, although I run the printer in an unoccupied room with the windows open. You should respect the chemicals, and always wear gloves and eye protection when working with them, but I find I only rarely have to do more than pour a little more into the vat.

This printer had been dogged with problems for me since day one, mainly issues with the prints not sticking to the platform no matter what I tried. I became an expert at cleaning up the mess caused by failed prints being stuck inside the resin tank, but occasionally managing to get a successful print by creating a platform to fill the entire print area. Most of the green resin that came with the printer was wasted like this, and when it was all used up I put a dust cover over the machine and let it sit for a few weeks, having lost interest in it.

I decided to come back to it because I needed a print for a project, the only difference this time is that I had bought clear resin instead of green. It was like a completely different printer!! Successful prints first time every time, sticking to the platform nicely, no slipping, no hanging off, no failed prints to clean from inside the resin tank. I couldn’t believe what a difference it made, and I had much better surface finish post-curing than I did with the green.

Goodness knows why they include the green resin as a starter instead of the clear. I can’t be the only person who experienced these issues with it. My only reason for 4 stars is that there are sometimes holes in my prints where an air bubble has been trapped under the platform, so it’s still not perfect.

Been waiting for resin 3D printers to come down to a ‘hobby’ price and have been really pleased with the results so far – I am using it to create parts for my car models – worked straight out of the box with amazing results – although there are alternatives, I have been using the software that came with the printer, and have also found the Anycubic resin to be great as well – although the printer will work with any resin of the correct spec. Easy to use, and a great support group online (Facebook etc) – has allowed me to produce parts that I could not make in any other way. Bought with the confidence of Amazon UK. Excellent product.

Coming from an FDM background, I thought I knew what I’d be getting into with resin – I was wrong! Initially the printer seems quite intimidating but in reality it is very straightforward to set up and use and I have not had a single failed print yet. The quality has been very high, and any defects on models have been due to me not placing supports correctly.

I had a small issue where I had a power cut and the printer stopped working after but a quick email to AnyCubic and the issue was resolved within a day – despite the timezone difference!

I mainly use the printer to print miniatures for Dungeons and Dragons and it is more than I could ever have hoped for in a machine. Learning to level the bed took a few tries but once it has been done properly once, it doesn’t need done very often at all. I would definitely recommend the Photon for someone wishing to print high quality pieces easily.

I use ChituBox slicing software and the Photon File Validator to make sure there are no islands left unsupported.

Overall, would definitely buy another Photon if I needed a second resin printer – it’s user friendly, great quality and has been very reliable so far.

I’ve had myAnycubic Photon for about a year, so thought it was time to post a quick review.

As well as a general curiosity with regard to 3D printing, I mainly bought this printer with a view to using it for 28mm miniatures, an application that I have been extremely happy with. Setting up the printer for the first time, in particular getting the levelling right, is a bit tricky, and I was initially frustrated. However, having persevered and tried a number of methods, I found one that worked for me and have had no issues since.

Some people seem to object to the smell of the resin, so you might like to think about where you’ll keep it when printing, and you will need a ready supply of nitrile gloves, isopropyl alcohol and kitchen roll, plus a couple of tupperware-style containers for cleaning up your prints. It’s not a quick process and can be quite messy, but that’s part of the fun.

The resolution and quality is truly astounding, I hope the pictures give you some idea (10p coin for scale) – it seems neither of my cameras is capable of capturing the close-up detail – I think that tells you something of the detail the printer is capable of producing.

I had recently bought the i3 Mega from Anycubic and have been looking at SLA printers to do fine detail prints

My hope is that at some point in the future I’ll be able to create miniatures and studio models and using a combination of an FDM (i3 Mega) and an SLA (Photon) will allow me to create what I need in a timely manner

The printer itself is 99% pre-assembled – the only thing i needed to do was attached the door knob at the front

I ended up with the transparent green resin which does create some really cool prints

Again with the i3 Mega if you follow the instructions in the Manual that comes with it you’ll have no issues setting it up and be printing with in about 15 minutes

I had read reviews and watched videos about the resin being smelly but honestly i can barely smell it – i would still take all the safety precautions though

I would recommend that you buy some additional things along with this printer:

– safety gloves

– safety glasses

– 2 x large containers

– 99% alchohol

– tongs

– UV lamp

The print quality is amazing and i cant wait to use it with my miniature production

I will say that i’m still getting used to the cleaning process – make sure you really do clean it thoroughly because if you dont and then cure the print you’ll end up with smooth artefacts where some left over resin was on the model

Also the resin is very brittle especially around the supports that are generated when creating the model code – so be careful when removing the support material

If you’re looking for a cheap and reliable SLA printer then you cant go wrong with The Anycubic Photo

I think the build quality is excellent, the level of detail that can be achieved left me speechless (I’m used to FDM print quality) and it was easier to use than I expected.

Out of 8 prints so far only 1 failed and that was due to my not cleaning the plate properly after the previous print (the print popped off the plate half way through).

Also the resin is probably not as robust as filament, so delicate items that require a high degree of detail would be recommended.

Ive been looking to buy this printer for a while now, and was pleased to pick this up on prime day

Printer was shipped quickly as usual and well packaged. It comes with a few tools, spare FEP sheets, gloves, instructions and 500ml of resin