3D Printer, Premium Titan Extruder Aluminum Double Linear

3D Printer, Premium Titan Extruder Aluminum Double Linear Guide Rails and Double Cooling Fans, Easy Assemble Printing Space 180x180x180mm

Kingroon 3D printer show

Premium Printing Quality

The printing results is premium. It deserve you own one to build your gifts for friends.

Users Show Their Artwork on Our FB Group

Our team really enjoy to see users to share and show their idea and artwork.

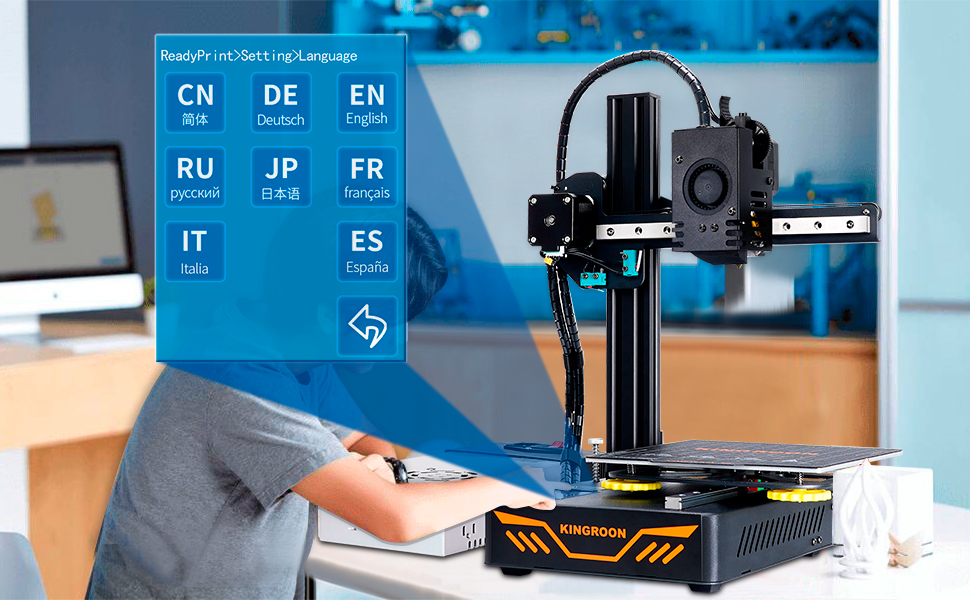

It is Perfect Gift For Beginners

This easy assembled 3D printer is a wonderful gift for kids, allow them to learn about how to build their confidence for DIY machine.

| Weight: | 7 kg |

| Dimensions: | 41 x 39 x 18.9 cm; 7 Kilograms |

| Model: | keepang20200116 |

| Part: | Keepang20200116 |

| Pack Quantity: | 1 |

| Batteries Required: | No |

| Batteries Included: | No |

| Manufacture: | kee pang |

| Dimensions: | 41 x 39 x 18.9 cm; 7 Kilograms |

| Quantity: | 1 |

Th is the newest version and it is excellent it has a retraction like the prusa mini

Nothing else on the market offers linear rails and a direct extruder for this money, making it great value. I have made dozens of prints in PLA and PETG and all have come out perfectly after some basic tuning of the Cura profile.

The printer initially appears very easy to assemble but there are a couple of issues you must be aware of. Firstly and most importantly the Z axis stepper may not align well with the leadscrew nut, if this happens the Z axis will bind up as it gets closer to the build area causing print artefacts. Mine was quite a long way out so slotted the mounting holes in the Z nut bracket. This will undoubtedly void warranty but gives a neat, rigid solution with zero binding.

Secondly some care should be taken when screwing the Z axis alloy extrusion into the base, there is some movement in the mounting holes so be sure to get the X axis at a perfect 90 degrees to the bed.

The fans are a little noisy, though there are plenty of 3d printable mods available for the hot end cooling that can use quieter fans.

Firstly, while it is possible to have the printer assembled in about 15 minutes and printing demo prints from the included (16GB blacked out kioxia in my case) uSD card, this is what you’ll probably find if you do:

The Z-Axis beam might be a smidge off square if you just slap it on and tighten everything up. check it with a square and adjust if necessary (I had to place a piece of folded up tinfoil under one side of the base of the beam to slightly ofset it back to square) otherwise you’ll end up with prints that lean by 1/2 a degree. this may not be important to you if you’re only doing decorative prints.

Secondly the Z-Axis threaded rod coupler is terrible and ideally needs replacing with one that fits tightly but in the mean time it will allow the Z-Axis thread to wobble and this will in turn show up as banding on the sides of your print as it pushes the whole Z assembly around as it rotates.

Again, this can be minimized by adjusting the threaded rod as you tighten the coupler. you can rotate the motor and watch the rod wobble at the top and adjust as necessary. or just get a better coupler…

The included magnetic build surface is also OK. It works well from an adhesion point of view but some prints will try to curl at the edges and lift the whole surface, so you still get the effect of prints lifting (squished corners) without it actually losing adhesion. a spring steel textured PEI coated sheet does wonders here and is easily the best upgrade you can do. ones made for the Prusa mini fit perfectly with a little overhang.

I found the printer was under-extruding and it turned out that extruder steps hadn’t been correctly calibrated. there are plenty of guides online for this so just search for “E-Steps calibration” to sort that out.

finally, don’t bother with the included version of cura, go and download the latest. it includes a profile for the KP3S already but it does have a slight problem in that when the print is finished it pushes the bed forward, to Y=300 which is more than the actual travel of the bed so it constantly bounces the maximum travel of the bed at the end of each print. This can be fixed by going into the printer settings and changing the End G-Code line that says “prepare for print removal” to have Y170 rather than Y300 (see screenshot)

The steppers are super quiet and when the fans aren’t blowing full tilt, this printer is nice and quiet. I shall be replacing the fans with quieter ones, but the hot end fan and the motherboard fan in the base are the worst offenders. Just about any fan would be better and there’s a 40mm to 30mm duct for the hot end on thingiverse just for that job. There are also better part cooling ducts around as the one included is pretty feeble, but does the job.

With all that out of the way, this printer now prints beautifully with enough accuracy to print the popular articulaed dragon (pictured) even down to 60% size with all joints articulating (some assistance necessary at the tail end but every joint freed up) using eSun bone PLA.

Now some important details: the power supply is a generic 24V PSU and I wouldn’t trust it for more than a couple of weeks of limited testing and will replace with a meanwell as soon as is feasable.

Also if you’re just printing PLA this next part won’t really apply, but if you plan on printing ABS or other materials that need a high bed temperature (and/or high nozzle temperature too) then the power connector on the base of the printer is known to not be rated to handle the current that the heated bed and hot end need to run reliably long term. So before the connector burns itself out, it’s recommended to add a heated bed MOSFET mod to take a power tap directly from the PSU rather than going through the flimsy barrel jack/cable

I like the easy and quick build. I use this printer for printing RC car parts where I need accuracy for fitment of bearings, not a problem for this printer straight out of the box is excellent quality.

Build quality is second to none. Don’t be put off by the slightly smaller build platform. This is the printer you should have bought first.

Superb little printer with many nice bits. X & Y linear rails, direct drive feeder, E3 V6 hot end clone, 32 bit main board, socketed silent TMC2225 steppers, magnetic build plate (which works a treat) and now for the caveats.

Be prepared that you might have to tweak the one you get… like most things Chinese, corners have been cut. The linear bearings may have some play in them. Easily remedied; dissasemble, clean thouroughly and replace the ball bearings with 3/32″ ones just as I had to do to my X-carraige. The X- axis drive belt was stupidly tight on mine, again easy enough to adjust. The X-Axis idler was also cross threaded and not at 90 degrees to the arm. Remedy- take it apart, retap hole and reassemble.

All in all, I consider these issues I experienced to be minor niggles and something easlily fixed.

So how does it print? Simple answer. Superbly. It’s easily on par with my two Ultimaker 2+ a printer that cost me roughly ten times the price of this little Kingroon and my Ultimakers are only 8 bit.

I was so pleased with the results I was getting that I bought a second one and happily that, out of the box, was perfect.

Recommended!

Let’s get the bad points out the way because there’s not many.

-It’s very noisy, the stock fans are crazy loud (roughly 69dB at 6″ away), I’ve since replaced these with some cheap 40mm 24v fans and a custom printed adapter (printed on the Kingroon) and its very quiet now (56dB) I can easily take work calls with it running next to me and its even quieter then my PC fans.

-This is a minor complaint but prints stick bit too well to the included build platform, which is better than not sticking at all I suppose! Anyway I’ve put a glass bed on it now so not really an issue for me and shouldn’t deter you from buying.

That’s it, an extra 20-30 spent, an evening putting it right and it’s an absolute beast of a machine now.

Onto the Good Stuff.

Things that surprised me at this price point:

-Linear Rails – this is rare for cheaper printers I’ve seen and they make it so much more solid, not to mention reduced noise when printing (once the fans are fixed).

-Touch screen – very nice addition and works well.

-Setup – it comes in two pieces pretty much, included documentation wasn’t great but I managed to set it up without looking at any reference material, I have 4 3d printers so maybe I’m not the best judge of this but I reckon you wouldn’t have any issues if this was your first printer.

– The pre-wired PSU – this is a nice touch and much safer than others I’ve used before.

– The spool holder – way better then some other I’ve had, its nice it was included.

– Build quality, this machine is solid, like more solid that it has any business being for this price, every part of it feels secure and well made, nothing needed tightening or adjusting out the box, just wow.

General good points:

– Print quality – Out of the box the quality you get from this with minimal tuning is way better than anything I could have hoped for, this is mainly down to the stock part cooling fan and linear rails. I’ve not pushed it too hard with detail but calibration prints, and general surface quality of what I have printed are wonderful.

– Bed levelling – while not as good as having bed mesh levelling out of the box, the included feature to send the print head to predefined points on the bed really saves time over doing it manually.

– Speed – i haven’t pushed it to failure but I’ve ran it at 80mm/s without issues.

– Direct drive extruder – I didn’t have to adjust this at all out of the box, it just worked.

– Hotend/Heated bed – this heats up much quicker than my other printers that run on 12v, for an impatient person like me its great. The temp holds well and doesn’t fluctuate too much which can cause issues with print quality normally.

– Bed Size – 180mmx180mm you don’t usually see this size for this style of printer, they’re usually 150mm which can be a bit restrictive, you really do notice the benefit of that extra 30mm.

– I Haven’t had a single print failure!!! – I can’t stress how insane this is for a new and especially cheap printer, you could partially put this down to experience but not a single print has failed out of the 50 or so I’ve done since setting it up, I’m not saying you will have the same experience but its a good testament to the build quality of the machine.

Notes:

– Print profiles for cura – I didn’t bother with the included software, you can use the Creality ender3 print profile in Cura and just change the bed size/print height and the start GCODE (change the 200mm line it draws to 160mm)

– The PSU not being attached could be a bit annoying if you have to move it around a lot, I’ve not included this as a real negative as most people will have a dedicated place for these where you could mount it somewhere. Or print a bracket to attach it to the printer of course!

I think all in all this is a great printer for beginners and long time 3d printers alike, its punching way out of its weight class in my opinion. Once I’ve moved and get all my printers setup this will easily take the number 2 spot behind my prusa but ahead of the creatlity Ender-2, Ender-3 and Anet A8. I’ll probably put a smaller nozzle on it and just use it for smaller higher detailed prints. But equally if it were my only printer I wouldn’t be looking to get a new one anytime soon!

I know this review seems overly positive but I’m very happy and I wasn’t paid to say any of this, I wouldn’t hesitate to buy it again, but if Kingroon want to send me another for free I won’t say no 😉

Good quality for this amount of money. Easy to use. Printing good when you put good settings.

Pros very nice compact printer, the linear rails and silent stepper drivers are amazing for the price, gives great print quality out of the box and was very easy to put together, 100% worth the cost and would recommend to anyone looking to get into 3D printing.

Cons the partt cooling is sub par and could do with a blower fan to be used instead of a basic 4010. Also one of the stepper drivers burnt out after a couple of weeks, couldn’t be bothered to go through Amazon for something small and easy to sort so I just replaced with a set of tmc2209 drivers I picked up on Amazon with same day delivery. Slot them in, adjust the steps per mm and printing perfect again 🙂

Let’s get the cons out of the way: The magnetic build plate has formed a couple of small bubbles and the firmware is a little bit odd.

The build plate is magnetic, which is great – but because the items on the build plate are rigid, larger items cause some suction underneath, and when you pull the build plate off, it causes bubbles to form between the magnet and the plate underneath, as well as inside the detachable plate.

The bubbles so far (after about 30 prints) are about an inch wide. It changes the height slightly, so the first layer is a bit thinner over the bubbles – but in general, it doesn’t massively affect the prints.

The firmware has some strangeness too. Pausing / cancelling is difficult – resumes usually over-extrude, and tends to cause some visible effects on the print – and you have to power cycle in between every print, otherwise it gets confused. One of the icons (changing the fan speed) has a rendering glitch too.

But aside from that, it’s a solid little printer that is fairly reliable. I would certainly recommend it to a beginner (with guidance) or hobbyist.

Really good little 3d printer. Easy to put together and up and running in 30mins.

The part cooling fan is on constantly which is annoying but the small footprint and linear rails , direct drive all add together to make this small printer a big performer and will watch to see if they release any new printers in the future.

Seriously easy to put together and setup. i was printing my first project in less than 30 minutes of receiving it!

properly strong build quality too. much more expensive 3d printers do not come close to this in build quality and print quality, and also features.

(Note: My photos are a mix of the “out of the box” printer and how I have it set up after a bit of use. I’ve got my own flexible bed in some of the photos rather than the included one for example. The other printer next to is is an ancient one with almost the same build volume(!) for comparison.)

The longer version – I’ve had a really old printer for many years (a Solidoodle model) and that is from an era when you had to constantly babysit the machine and modify every component to your needs. So my mindset is that the 3D printer is something you tinker with as much as use to print things. This Kingroon device is very different, it’s a tool that does a job to a good level with minimal fuss. A real step up at a fraction of the price.

Opening the box is the first time you’re impressed. The packing is extremely good. Nothing will be damaged in transit as foam cut-outs support everything. Assembly is absolutely minimal, mere minutes. This is not a kit printer, it is shipped more or less ready to go. I think I fitted in 4 or 5 screws and that about it. You also get EVERYTHING you need in the box. All the hex keys, all the tool and even spares of everything you might need. You also get a spare nozzle and temp probe. This is really above and beyond, I was very impressed.

When passing in the filament the path way is tight and the very small winding of the sample filament means it has a strong curve on it. So cut the end into a long point using the included snips and it’ll thread a lot more easily. The included snips are great, another nice bonus.

Levelling the bed is closest to “hassle” the set up gets. It takes a few minutes and you’ll want to do it at least twice to make sure it is right. A badly levelled bed will cause no end of frustration so its worth doing right. It would have been great to have automatic bed levelling as thats more or less standard in 2020 but at this price I totally understand the omission. The additional 10 in parts would have pushed the price up, and the weight on the gantry would have maybe required more expense there. I understand the limitations of the price. So to that end I really liked the touch interface levelling, the very large and easy to reach levelling wheels and the 5 point system. It was “fine”. A key point – once I had it levelled it didn’t drift, I only had to do it once.

I used the “A4 paper” method – take some plain printer paper and place it on the print bed. As the head comes down to the surface drag and push the paper. There should be resistance but it should move. Rotate the wheels as necessary. If you need to move the bed a lot you can move the Z-Axis end stop by rotating the small silver wheel by the screen, this moves the overall “0” point for the axis.

The PSU is an external unit and pretty large. But this is a good thing in a way, it has plenty of power and got the bed up to temp extremely rapidly. The system runs at 24V, which is a good choice and will get the best from the stepper motors and heat bed. The PSU also has a good shroud over the connectors with a proper power switch, some other cheaper printers have screw terminals which are dangerous for domestic use, this is much better. The only problem with the PSU is that the fan comes on when a lot of current is being drawn (ie using the heat bed) and it is surprisingly loud. I might swap the fan for a larger/slower one to help with that.

I then used the included filament sample and the bundled SD Card to print a test file. You really do get everything you need in the box. It worked first time. Genuinely impressed with the quality. The first bit of filament out of the nozzle was read whereas the sample was blue, so clearly the hotend and nozzle had been tested during assembly and the nozzle was probably tightened when up to temp. This is good, that filament in the nozzle was a sign they’ve done their quality control at the factory.

In operation the stepper motors are very quiet. The stepper drivers are very quiet. The linear rails are basically silent and ran very true. I didn’t have to alter the tension on the wheels at all and there was hardly any play in the gantry. In fact there such a small amount of play I’m very happy with the gantry design compromise. Yes it isn’t has stiff as a more traditional layout but its small and they can make it cheaply and it works very nearly as well. There is some surface shadow artefacts if you print fast which I think are from frame wobble, but its better than I’d hoped for at the price and we have to be realistic.

I’ve done test prints at everything from 60 to 150mm/s. I think the sweet spot is 0.3mm layers at 100mm/s. Because of the compromise on the frame design I don’t really see the point in 0.1mm layers of other very fine settings. I think you get 90% of the result in a fraction of the time at 0.3mm and 100mm/s. The corners and shadowing is better at 60mm/s but its diminishing returns and I prefer quicker results.

The only design “flaw” I’ve found is that he SD Card slot doesn’t fill the cut-out in the metal frame entirely. It is easy to miss the slot and post the card into the gap. You then have to disassemble the machine to recover it. I used some tape to mask the gap off.

I had some problems with ooze from the nozzle with PETG. Dialling in the temps might help. It wasn’t a deal breaker, just a bit irritating as it can mark the surface or cling to the nozzle due to the lack of sock. A better heat-brake cooling fan might have also helped. But I think experience of this machine will enable it to be configured to minimise it, I’ll keep experimenting. And the “out of the box” stuff was fine.

Dimensional accuracy was also good. Within 0.1mm with cheap generic filament and no dialling in. Good enough for mechanical parts.

The metal for the frame body is thick and sturdy. It is nicely finished and there are no sharp edges or anything that smacks of “budget”. Considering the slight design its very sturdy once set up… and VERY small. Truly a shelf printer.

I opened the frame and had a look at the logic board (see picture) and its a nicely laid out ARM based affair. I haven’t messed with it at all but it looks like it could be tweaked and expanded if you wanted to. Everything is very well labelled and socketted.

I didn’t use the included software at all. I used a stock install of CURA and entered the appropriate settings in the setup wizard. It worked perfectly. The manual is very good and has the technical listings you’d need to get this printer working with any software.

Before buying this I read and watched some reviews of the previous model (the Kingroon KP3) and the complaints voiced there, such as the bed going over the screen and the wheels not running true, have all been addressed. I don’t have a KP3 but from the reviews this is incrementally better in every area.

Upgrades I’d make – This is a budget printer. I’m not going to double it’s price by fitting a fancy extruder or even a new hot-end. But a good E3D nozzle and a silicone sock make a lot of sense. I’m also going to replace the fans with quieter ones, probably 40mm versions in a printed bracket and something large on the PSU. This will hugely lower the running noise. Beyond that I can see myself altering very little.

I don’t think this printer would handle ABS printing well as the bed is very exposed to temp variation, but I didn’t test so can’t say for sure. I also didn’t test exotic filaments or flexibles, I think a better nozzle would be needed for anything too special. For the budget user I think PLA and PETG are going to cover most use.

Final words – I’m amazed what they’ve done for the price. An unrealistic purchaser could pick fault with any part of it. But the value is great. And it all works. There are compromises but the right ones have been made and they’re well balanced. Its safe and it works. I’m delighted.

The screen is small but most settings are done in the supplied software – which is a version of some quality slicing software that is dedicated to the particular model of printer. That’s no bad thing as the settings are already dialed in for the machine. The screens user interface is fine with all the important details – temps, progress bar etc are clearly obvious. For me the screen is big enough as the fact it is full touchscreen and needs no buttons far outweighs size. Notably they moved the screen to the top of the base, so at desktop height you are comfortably viewing it downward. The previous model was at the front where the moving base could obscure it. The fact this has changed suggests this is a company that listens. Comes with a spare nozzle, thermistor (I think) and all the tools you need.

It comes in 2 parts that bolt together and the lead screw – all put together in a few minutes. There is no wiring or anything else – this isn’t a kit by any means Bed leveling with the huge adjuster wheels is really quick using the really simple touchscreen bed levelling instructions. Unusually the bed levelling uses 5 points. So after 4 corners it goes to the middle. This proves the bed they supply is absolutely flat. I was printing my first item in less than 15mins. The little figurine printed very fast and the finish was very good. Because this printer is so stocky the rigidy is there even though this style of printer has the potential to lack that. It’s all about size – its pretty small but the extrusions are thick and the base very heavy and rigid.

The build area (180mm cubed) is pretty big whilst the machine itself is surprisingly compact. I have tried several budget 3D printers and this one is the first where there are no obvious compromises. It looks built to last and there are no obvious weak points – like the dumb plastic gears in my last ones extruder.

This 3D printer seems overall a great buy and only time will tell if there are any weak links.

I watched few videos on YouTube before to buy it to see the quality and I can say the quality was good as I expected ,, it took me a bit to set the assets and get i it work but once is done works fine so far ….I did not used software just tested on the ubs key so far but works fine with the pre-defined objects