Official Creality Ender 3 S1 3D Printer with Direct Drive

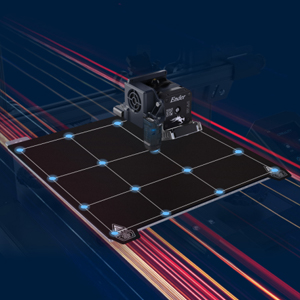

Official Creality Ender 3 S1 3D Printer with Direct Drive Extruder CR Touch Auto Leveling High Precision Double Z-axis Screw Silent Board Extra Glass Bed Printing Size 220x220x270mm

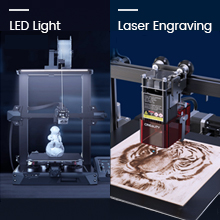

Creative Potential

With preset interfaces for laser engraving and LED light Ender-3 S1 brings you more possibilities.(Laser engraving and LED light need to be purchased separately.)

Knob Type Belt Tensioner

The belt tensioner is an easy-to-use tool that helps prevent problems such as layer shifting caused by inadequate tightness.

Upgraded UI Interface

The 4.3-inch knob LCD screen features a brand-new Ul interface to facilitate simple interaction that allows you to experience operation by knob. It automatically dims out when inactive for 5 minutes, saving energy and protecting the environment.

High Filament Compatibility

Direct extrusion supporting flexible filaments, Compatible with more filaments, it can print PLA, TPU, PETG, ABS.etc.

|  |  |  |  |  | |

|---|---|---|---|---|---|---|

| Color | Black | White | Grey | Blue | Red | Yellow |

| Weight | 1KG | 1KG | 1KG | 1KG | 1KG | 1KG |

| Dimensions: | 48.7 x 45.3 x 62.2 cm; 9.1 Kilograms |

| Model: | Ender 3 S1 |

| Manufacture: | Creality 3D |

| Dimensions: | 48.7 x 45.3 x 62.2 cm; 9.1 Kilograms |

| Origin: | China |

Ich habe mir diesen 3D-Drucker gekauft da ich ihn in dieversen YouTube-Videos als Empfehlung fr Anfnger gesehen habe.

Diese Rezesionen kann ich nur besttigen.

Der Aufbau ist schnell erledigt, die Baugruppen sind sauber und gut verpackt vorbereitet.

Etwas Sorgfalt und ein wenig technisches Geschick sollte man aber dennoch haben.

Etwas Kleinwerkzeug wird mitgeliefert, dies ist fr den Aufbau und die Justage absolut ausreichend.

Mit einigen Tipps aus den Videos alles eingestellt und die ersten Modelle gedruckt.

Das Ergebniss war super und hatte ich so nicht erwartet.

Man bekommt viel fr sein Geld und die Bedienung gibt nicht viele Rtsel auf.

Als Tipp fr Anfnger so wie ich: macht am Anfang nur Versuche mit PLA und lernt wie man mit Cura (oder einer anderen Software) die Richtigen Einstellungen dafr und fr andere Materialien findet.

Ich hatte ganz euphorisch nach den ersten erfolgreichen Drucken zu TPU gegriffen und mir damit beinahe die Druckbettauflage vernichtet.

Es macht sehr viel Spa mit dem Gert zu drucken und bei mir luft das Gert an jedem WE fast den ganzen Tag.

Ich finde immer wieder im Netz etwas neues das man im Haushalt oder Hobby gut gebrauchen kann.

Das Gert ist fr Anfnger sehr zu empfehlen.

s bonne machine simple et efficace pour un enfant de 14 ans

I have been happy with the Ender 3 S1. The printer is good quality and works well out of the box. If and when you need support please understand that you will get “email only” support from China. All replies will be delayed a day or two. I was promised warranty parts 3 weeks and and had received nothing. The seller did reach out to me to make things right. I did receive my warranty parts.

China celebrates new years for a few weeks in January. This is what caused delays in my warranty parts.

The included build plate is terrible, it’s akin to using a piece of slightly rough paper to print onto. You’ll need a lot of supports to get reliable results on this plate, though Creality also sells a higher quality magnetic build plate which I would highly reccomend.

The bed levelling is all manual, bar the limit switches included in the kit. Due to the nature of this being a self-assembled printer, the placement of the limit switches can dramatically change print quality, and you’ll find yourself needing to manually twist the knobs underneath to straighten the bed, as well as manually inputting a print offset if the limit switch is off. This can all be rectified with a BL/CLTouch module, but a shame that such a mechanism isn’t included.

The noise this thing makes is quite annoying. Prints can last for hours (not much can change this), but to have a loud fan constantly whirring, and the sound of the motors constantly actuating makes it a little annoying to be in the room with. Personally, I’ve replaced the motherboard in favor of Creality’s silent motor driver board, which certainly cuts down on the noise from the motors, but the fan is still rather loud (as audible in the attached video). I’ve heard it can be replaced, but haven’t tried myself. It’s a shame a quieter one isn’t included as I could just about live with the motor noise on its own.

Overall, a wonderful printer, I do not regret my purchase one bit especially at the price!

Don’t plan on SD card reader to remain working, had to switch to direct to pc to get files to the machine. But really no major issues after running it for hundreds of hours so far. Easy to use, easy to assemble, strong and ridged printer.

The first prints using the included white filament were great, I was very happy with it. The other prints have all been successful so far and have been very impressive and I’ve had no failed prints yet.

The only issue I had was the print’s literally being welded to the print bed. Not sure if that’s my fault or what but I purchased a magnetic print bed separately and that has made a huge difference to taking prints off. It just pops off with the print and bends to allow the print to be removed.

It’s not terribly noisy, just a hum from the fan that lets you know it’s there.

I really can’t fault it for the price I paid. Just that extra upgrade for the magnetic bed which was 22.00 and it’s worth the price to save breaking prints or doing damage to the printer. So far so good.

I had previously left a poor review of this machine and returned it. My friend purchased the same machine and showed me what I was doing wrong. It seems like this is a great printer if you have some previous experience in 3D printing. I thought it was just a one step setup and go. There was apparently a bit more to it. The instructions that come with the machine are minimal. I took a look on YouTube yesterday and there are many videos on how to properly use the machine. I didn’t realize this prior.

My conclusion – Likely a good printer if you have experience. Spend some time watching usage videos on YouTube to get a better understanding of the system. I might re-purchase it in the future.

3d printer came practicly perfect out of the box , minus the bed having small warp and needed to tweak the wheel under it cause one of them was not screw in enough . all in all 10min later it was already printing the test! Came in with small roll of white pla filament for testing but no pin to hold the glass bed in place while printing (bed may shift during printing if not hold in place )

Took me 2-3 hours to put together but there are lots of tutorials online. I’d say you need to be not completely thick to build but otherwise farily easy. Started my test print and worked great. excellent first printer for me.

Nachdem ich mit Sovol auf die Nase gefallen bin, habe ich mir wieder einen Creality Drucker angeschafft. Gut, das angebliche Aufbauen in 30 Minuten, wie so gerne alle Infuencer beschreiben, stimmt natrlich so nicht, aber das wusste ich bereits, denn in China wird natrlich unter Druck und Accord gearbeitet.

Die Teile sind alle sehr hochwertig verarbeitet und auch sehr przise gefrst, das hrt dann beim Zusammenbau im Werk schon auf.

Die Laufrollen waren teilweise so fest, das Abdrcke vorhanden waren, dann bitte lieber locker lassen! Die Rechtwinkligkeit muss vom Portal auch berprft und eingestellt werden.

Da ich sehr pingelig bin, habe ich mir auch Zeit gelassen, damit ich keine Fehler mache, und brauchte ca 6 Stunden dafr.

Es hat sich aber gelohnt, und man bekommt seine Besttigung beim ersten Druck, Perfekt.

Der Drucker kam schnell und gut verpackt an und ich konnte das Gert alleine mit Hilfe der Anteitungen und Produktvideos zusammenbauen. Inbetriebnahme war kein Problem mit der mitgelieferten Software auf SD-Karte. Zubehr ist sinnvoll, nur die Spachtel ist Schrott. Service von Creality funktioniert sehr gut und hat mir geholfen, wieder an die Dateien zu kommen, die auf der SD gespeichert waren; diese musste aus mir unerklrlichen Grnden neu formatiert werden.

Die Qualitt der Ausdrucke ist gut. Fremde Hilfe habe ich bentigt bei der Erstellung eigener Druckmodelle und dem Umgang mit dem CAD-Programm und dem Slicer. Es ist ein groer Vorteil, dass es dazu gute Freeware und Bedienungsanleitungen im Netz gibt! Das oft stundenlange Warten auf einen vollstndigen 3D-Druck nervt, ist aber bei vergleichbaren Druckern auch der Fall.

Das erzeugte Interesse beim Umgang mit dem Ender 2 S1 ist grenzenlos und lsst auf weitere zufriedenstellende Beschftigung hoffen.

I cannot get over how good this printer is out of the box. I’ve been into 3D printing since the reprap days and built my first i3 back when laser cut wood frames were a common thing. Over the years it’s been great to see many companies come out with improvements to the i3 design. I think with this printer, it’s reached its peak. I cannot believe the quality of prints that this printer outputs. At arm’s length, some of them even look injection molded.

My only knock on the design is the flat ribbon cable that goes to the extruder. It seems like it gets bent at a rather extreme angle during printing, and I can’t see it lasting very long after repeated movements like that. I’m sure there is a mod out there that will help relieve the strain.

Comgrow read my review and honestly went above and beyond to fix my issue. It’s true that the printer died on me, but they sent me the correct parts to fix it. Swapping out the parts was pretty painless as well and now the printer is working as it should. There are a few issues with the printer, but getting proper support is not one of them.

—- OLD REVIEW:

I have a number of 3D printers running to support my business. I have used a number of different printers, and I could not recommend this printer to anyone. The CR-Touch auto bed levelling is very, very inaccurate. I find myself having to relevel the bed almost every print. I have bought a total of 3 of these printers, and one of them has completely died on me 4 months later. While talking to Creality support, they want me to disassemble the printer, buy a multimeter, and start sending them back certain voltage readings on the main board. They refuse to help me unless I do the above. All in all, this printer is absolutely not worth it.

I ordered the Ender 3 s1 printer Nov. 14/22 from Amazon and got it Nov. 17/22. Very fast service. I also ordered the all metal w Kit High Temperature 300 Titanium Heat break Plated Copper Nozzle Upgrades for Creality Ender 3 S1 the same time and installed it right away. This printer has been printing every day since I got it and I have not found any problems. The prints have come out prefect.

I highly recommend this printer to anyone. The Main reason for purchasing this print was the CR Touch, Dual Z Axis tied together with the belt, and the new Sprite Extruder Heater Block. Creality did a good job with this printer. It’s worth every penny.

There are several features to this model that are particularly valuable. The AUTO BED LEVELING is a welcome advance. It is so simple that I routinely reset for each new project. This is probably not necessary, but since it is so easy to accomplish, it makes sense to verify a level platform (bed) to ensure a quality print. The DIRECT DRIVE is terrific for advancing the filament and makes it relatively easy to change filaments. The digital display is excellent and fairly intuitive. It gives fine control over bed (platform) temp, nozzle temp, movement of the extruder assembly, etc. The MAGNETIC platform cover that attaches to the platform is a nice addition. It is flexible and allows for an easier removal of the finished print, always an issue requiring putty knives and all manner of razor blade accessories and chain saws.

One caution for new users (and a reminder to veteran users): verfify “Z-offset” (the distance between the tip of the nozzle and the platform surface; controlled from the digital display) before each new project. Removing the magnetic plate (or glass, or whatever surface you print to) can change that distance (supposed to be one sheet of paper between the tip and the platform). Failing to do this can influence whether the first layers of the print adhere properly to the platform and could result in the print pulling away from the platform as printing progresses. That will require some cleanup and restaring the job.

For new users: 3D printing takes time; it is not a process that results in instant gratification. The rate of plastic deposition is necessarily slow so each layer properly sets before a new layer is added. It is not uncommon for projects to take hous or even days for large prints. Don’t be too quick to blame the machine for slow printing!

SUMMARY: ease of use, good resources for setup and operation, advanced features, and competitive pricing make this unit great for new users and accomplihed users as well.

Been using this printer for months and its a workhorse. I’ve had one issue related to upgrading the firmware. Thought I bricked the printer using the correct firmware on Creality’s website. Luckily I found someone on Reddit that uploaded a firmware that fixed the printer.

So far the firmware was my only issue. Prints have been great whether they were printed with super detail or standard detail. I still don’t know if I’d call any 3D printer “beginner friendly”. This was pretty close to pull it out of the box and start printing though.

I was able to printout a few dnd mini’s but this printer isn’t really meant for mini’s so if your looking for a printer for mini’s I’d recommend a different printer. My main use for this is cosplay props.

If you’ve got friends with an older Ender 3 you’ve undoubtedly heard the endless issues they’ve got with upgrades and addons. If you’re looking to avoid the hassle and cost of upgrades, this is the perfect machine as it’s ready to go and build excellent prints out of the box. The construction is solid and feels well made, the pieces were easy to put together and all the features like bed levelling were fully functional from day 1. An awesome introduction machine for anyone interested in 3d printing without the nonsense.

Excellent value of money for a beginner like myself, fairly easy to assemble with instructions and a bit of YouTube would recommend to any beginne

Bereits die Testdateien liefern berraschend gute Ergebnisse. Der erste Druck von Thingiverse berzeugt ebenfalls.

Ich bin gespannt was alles mglich ist.

Volle Kaufempfehlung.

This is my fourth 3-D printer overall and hands-down the easiest to use it took 20 minutes to assemble following the video on the card I download the latest version of their slicing software from their website selected the proper printer from the drop-down menu and started at it. it has been running continuously since I got it without issue there’s been several power outages and it’s been able to pick up without a problem,the print quality and detailing is incredible it is easily the best printer I’ve ever used and I’m so happy to have i

I did end up haveing a thread stripped on the hot end assembly, and in my search for a replacement stepper motor, (the housing is drilled and tapped) i ended up talking to comgrow… thier service is beyond anything ive seem in my lifetime. They make sure your satisfied before ending the conversation. Without a doubt in my mind, i would suggest getting anything from comgrow based on thier customer service alone.

Dont get me wrong here, the S1 id a great machine, the issues i encountered were from poor shipping handlers, and cosmetics.. its a well built, sturdy machine that really does go together in about 20 min. With little effort.

Great printer for beginners. Very little setup needs to be done. What’s up in printing within an hour. Would definitely recommend making sure everything is tight And that the bed is level before your first prints. As the x-axis was very loose and the bed was not level at all. Besides these minor issues all Prints have come out perfect.

I had an ender 3 with all the bells and whistles and it was time to upgrade. I sure am glad I did. A simple z axis adjustment and it was printing perfect prints right out of the box!

The only thing to note is that Cura does not have a profile for this printer yet so I had to make my own.

First 3D printer I have bought. Got it for my 11 year old. Found it fairly easy to assemble with the instructions. Plenty of help online about setting up this printer and within a couple of hours of receiving it, started printing. Good quality prints from what was installed on the memory card. Plenty to learn about setting it up and playing with the settings, or just download pre-done designs if you wish.

I am a complete newbie to 3D printing. The machine arrived and needed assembly and that was a daunting task at first but with a little video tutorial help on YouTube I figured it out. Once I had the plate levelled and knew how to get started I printed one of the test prints which came out great. After some investigation I discovered a 3D drawing app and downloaded a slicer program and have within 24 hours learned how to design and print my own creations. I would say I have average technical ability. Great product for a starter.

I sent the other back as it really did not feel well built and had a small print area and decided to buy the Ender 3……. money very well spent most definitely.

Setting it up is very straightforward and ot all seems well built and solid.

The Creality printers can be upgraded for little money and very easily.

I did have a screen issue but the service team rapidly sent me a new one and all was very good.

If you are looking to have a go at 3d printing then this is a great printer to buy backed by fantastic customer support.

Buy one you won’t regret it !!!

Have not need tech support but there is tons of useful information online

The Good: This printer was very easy to set up and get going. I had a Monoprice maker plus before but it was getting old and unreliable. This new printer made me wish I had replaced it a long time ago. Leveling was very easy and the auto level function keeps things in check. I have already done 40 hour prints with no issues. The flex base is fantastic for adhesion and printer removal (I do recommend using a glue stick). Love this printer

The Bad: The printer broke within a week. The wire to the thermistor snapped. Customer service was great though. They responded quickly and sent 2 replacement thermistors, so I was back up and running in a couple days and have been printing continuously for several weeks now. So wile having the printer break after a week the remedied it in a fashion that I would definitely purchase from this company again.

Stable, une fois le premier rglage pass, imprime sans erreur.

Trs bon produit, je recommande

Tout fonctionne a merveille seule bmol manque rglables pour fil pteg dommage

Printer printed great for about a month. Great quality, super easy to use.

Then I started having issues.

Layer shifts on multiple prints, the official laser attachment would no longer works, the creality light bar stopped working as well. Narrowed it down to an issue with my mainboard. It’s past the 30 days so I can’t return or exchange and Creality Customer Service doesn’t exist I have called, emailed, tried the online chat , I’ve gotten one response asking what firmware I’m on (3.0.3) and was told to download 1.0.6. Which you can’t find. Which also does not work with the F4 chip that they shipper my printer with.

Update 5/23/22

Seller has gotten in contact with me and is working quickly to resolve the issue

I’d say it’s a good printer. Mostly what I am looking for, something good out of the box with out endless tinkering nor spending an arm and a leg. My only complaint is that the bed was wobbling in the X direction due to loose rollers. Which I had to take the bed apart to fix it.

This printer now works even better using Klipper.

ice product All mods on you tube and others are done on this machine great prints out of box buy it .

i had a 3d printer years ago when the tech was fairly new to the world… i eventually left 3d printing – but recently had a need for a few small parts, so i thought I would just get an entry level model.

i am extremely impressed by this printer. the print quality is dramatically better than my old robo 3d (of course, its been 12 years, so a lot of improvements have come around) for a fraction of the price.

the only downside to this printer is the bed – the stock bed is arguably terrible. the prints are almost impossible to remove. thankfully, creality made this with a magnetic base, so changing it out to a pei bed is simple. just plan on that additional purchase.

Der Drucker (Ender 3 S1) ist fr mich definitiv der richtige Einstiegsdrucker gewesen! Tolle Druckergebnisse, schnelle Erfolgserlebnisse und hat definitiv dazu beigetragen, dass ich rund um die Uhr drucke. 😀

Die Lieferung erfolgte sehr schnell, der Drucker ist fabelhaft verpackt, sicher, ordentlich, strukturiert. Das Aufbauen ging auch Recht schnell, ca 30 Minuten, wobei ich hier den einzigen Kritikpunkt anmerken muss: die Anleitung ist viel zu klein gedruckt, manche Stellen hatten dann auch besser beschrieben werden knnen, aber alles definitiv machbar.

Mit der Herstellersoftware von Creality hatte ich leider keine USB Verbindung aufbauen knnen, auch waren hier die Sttzstrukturen nicht automatisch aktiviert, sodass mein zweiter und dritter Druckversuch in die Hose gingen. Aber mit Ultimaker Cura (Freeware) was das auch kein Problem mehr. Direkt nach der Installation war der Drucker ber USB ansteuerbar und die Einstellungen super. Die Druckergebnisse waren ab dann echt toll, ich kann den Drucker einfach nur weiterempfehlen. Bin gespannt, wohin die Reise noch fhrt und ob Creality noch eine MultiMaterial/Multicolor Lsung bringen wird.

icamente decir que se escuchan los ventiladores muchsimo menos que su anterior compaera la v2 tengo las dos y estoy muy contento con ambas. La calibracin automtica simplemente es una ayuda porque hay que calibrar la con las cuatro ruedas como siempre.

You can make anything, repair that broken plastic part,or make an articulated dragon. The print quality is very good. Go on treat your self, you deserve it. Recommend to everyone from beginners to advanced.

This is a nice printer for the price, it’s easy to set up and use with the program provided. the one thing I will advise anyone getting this is to get a glass plate as it makes it easier to remove the print and also heats up better and more evenly.

I currently have 7 running printers in a print farm business and have had several other in the past including the Ender 3, Ender 3 pro, Ender 3 v2, Ender 5 Plus, Prusa I3 and some other brands.

I have to say by far the Ender 3 S1 is by far the easiest to setup, easiest to use and best functioning printer I have, I would go as far as to say it rivals the Prusa I3 in some categories. The Prusa is a very hard to beat printer but offers amazing results after you spend weeks tweaking it, and yes my I3 prints are better than the S1, but not by a huge margin. The big difference is I take days or weeks to dial in the Prusa, the S1 I use the Creality Cura profile and click print, no issues at all.

My S1 has been printing non stop for almost a month now and the only thing I changed so far is the the nozzle, I didn’t even relevel the bed after changing it and just went for it.

In summary I think the Ender 3 S1 is finally the first printer that is ready to be used by almost anyone with little to no knowledge of printing, it just works, everytime.

The only cons I really have about the printer is the jerry rigged looking runout sensor, but the sensor works fine, it’s just a poorly designed system from a visual standpoint, it just loosely flops around.

I am giving this product five stars after modifications, and four stars as is.

The ender 3 s1 is a big step up from the ender 3, having experienced both printers myself. Most accessories that ender 3 owners would implement are already present in this model. It is a hobby printer but I was able to print very accurate parts using Cura’s super quality at 50 mm/s. The stepper motors are pretty loud when using auto-home, but during printing, they are hardly noticeable. The stock fans, however, are quite loud, and that may be problematic for some. There are some other features I wished were more refined, but most can be solved with a few modifications from Thingiverse files and different hardware if you are willing to go the extra distance.

Creality recommends using their slicer, but personally, I prefer Cura. I attached the starting G-Code I used: it’s the same as Cura’s G-Code for the Ender 3 Pro, but with a line that references the auto bed leveling since I was having trouble with the first layer despite having the bed be within 0.2 mm difference across points.

Pros

-Great print quality

-Easy to modify

-Pre-built (mostly)

-Comes with extra features not present on previous models

-Direct-drive extruder: can print with TPU (flexible material)

-Aesthetically pleasing

Cons

-Loud stock fans

-Hot stepper motors

-Ribbon cable and filament sensor not securely attached

These features were fixed with an attachment over the extruder, heat sinks, and other 3d printed parts, respectively.

Overall, it’s a great printer and easier to use than the Ender 3 Pro. I would recommend watching a review video on YouTube to see the aspects of the printer in-depth.

I have never had or used a 3d printer before now but I have watched a lot of videos about 3d printers, so bed-leveling and temperature-setting were simple and easy to do with the provided equipment and software.

The machine itself isn’t super noisy or bulky, you could easily set something like this up in your dining room or crafts room on a small table,start a project and walk away from it for a few hours and forget that it is running.

I am now partway into my first printing project,the test pig,and I was pleased by the fact that with no experience whatsoever I was able to get good bed adhesion and proper leveling going off of tips and hints that I picked up from the internet. I have no idea whether the lamination or layer evenness or any finer details will be poor,adequate,good,or excellent at the end of this print,which is why (and the only reason why) I have given the product 4 stars in these areas. I expect they will be very good based on what I am seeing now.

Overall,the main thing that has kept me from getting a 3d printer up until now has been price,accessibility for a new user of this type of product,and fear of getting it out of the box and discovering that I have no idea how to properly set it up or use it even with adequate instruction,and worry about spending a lot of money on a machine I don’t use because something about it didn’t measure up to my expectations,but the Creality brand and the Ender 3 model are both well-established and have tons of information and support out there to help you with any issue relating to setting up or using the product,and honestly,the instructions and parts included in the box are good enough to get your machine properly assembled. I am so,so pleased with the quality of this 3d printer and feel like a wide-eyed kid watching this little machine conjure a plastic pig seemingly from thin air with its mesmerizing whirring dance.

I have not been paid or given anything by Creality or the seller to leave this review or say anything about this product,neither positive or negative. If you have never owned or used a 3d printer and you are reading these reviews and thinking about purchasing one,just do it. Get the Ender 3. You’re not going to be disappointed.

Returned an ender 3 pro for this model does great in 20 mins of setup

Pro’s:

1) Comes mostly pre-assembled, about 80%. There is very little fidgeting and ways to mess it up.

2) Has 2 z-axis screws, a must for any 3D printer.

3) Has auto bed leveling, another must.

4) Has nice lcd display.

5) Direct drive extruder and a filament detector, a nice plus.

Con’s:

1) The included spring steel bed wasn’t too good, had high low spots, get a PEI bed.

2) You do have to check and play with the belt/roller tensions in order to dial in your printer.

3) The display doesn’t allow for changing a lot of settings , where is the flow rate setting?

4) The filament detector didn’t seem to detect filament tangle on the spool that stopped the filament. Almost ended up damaging the printer if I hadn’t caught it in time.

Printer was quick and easy to set up. I was printing within 10 minutes this is my first printer so we will see as we go

Easy to setup, this is a grumble from all users of all ender 3s takes a long time to setup not this one out the box assembled and auto set up and start printing

This little fella is fantastic for PLA prints, maybe petg and/or abs though I haven’t tried that (yet), what I can tell you is that this has got to be the best thing for a beginner, if you can’t make it work you should find a different hobby/job

1sy time using a 3D printer so I was a bit hesitant, but this has been a joy to use so far, and the included Creality Slicer turned out to be much better than I expected, once I watched a few YouTube videos. I have printed several projects now, small to big, and only one failure, which may have been from a slightly loose stepper belt. Even when first unboxing, be sure to check and tighten all fasteners and check belt tensions.

Cons: the extruder head had a bent connector (see picture) who interfered with the installation and the fitment of the head to the metal support on the x axis. I had to bent it back carefully by myself, with the risk to crack the two small connectors. I think this is the most important and expensive part and this should not happen especially when you pay almost 600 dollars.

For the rest i would strongly suggest this printer.

UPDATE: the seller contacted me to ask more about it and offered me the spare part at no extra cost.

Im super new to the 3d printer scene, so i had alot of questions. I msgd the seller with questions about building, maintaining and properly running my ender 3 and they were always quick to respond with a solution.

good print ,just no automatic level ,need adjust 60% of time

Amazing little printer for the price. Nothing but good things to say about it. Print quality is great for the price point and the “mod-ability” of it is amazing. After about an hour of assembly I was printing stuff. Great machine for beginners as well. Creality is great to deal with on the warrenty front as well. Had an issue with the control board on my unit and creality sent me a new board for the unit in record time. If your new to the 3d printing scene or even a seasoned pro looking for a pet project I cant say enough good things about the ender 3.

The Ender 3 is a great printer for anyone who wants to get into 3D printing. Assembling the machine helps you understand the concepts and adjustments that can me made to get the best out of your printer. There are plenty of videos on YouTube which will help with assembly – if this is your first printer, definitely check them out.

Make sure you take your time to put it together properly and that the bolts and belts are all right enough. Some of the preassembled parts may have loosened on their journey from China so it’s worth checking them too.

Very impressed with Comgrow. As soon as the printer arrived I received an email offering help and support if I needed it. Great service for a budget printer.

The print quality for a machine of its price is astonishing. I would recommend the free Prusa Slicer which has preset profiles for this machine – you’ll get great print quality and I think it is a little quicker than Cura too.

All in all, I am very pleased with this excellent value printer and impressed with the attentive customer service from Comgrow.

I absolutely love it!! My boyfriend bought his render 3 pro just after Christmas and he decided to get me the render 3 just so I could leave his alone lolll. The print quality is fabulous. For beginners it’s perfect and won’t cost you too much. For the price it’s excellent. I started printing within an hour. I’ve printed differs accessories for my printer and I’m just loving it!!!

The printer came very smartly packaged, with everything included in separate packets. All screws came in their individual packets making it very easy to sort them out.

Putting it together wasnt as much of a hassle as i thought it would be. The instructions are OK, just a bunch of pictures on an A3 page. I recommend watching a youtube video, i managed to get mine build in roughly 2 hours working fine.

The printer also comes with an SD card, and USB converter/adapter. This has some test files and the software for the printer.

Easy to control, and work with. I recommend this printer for all starters.

This is a great quality for price 3d printer, i love the glass bed i comes with and the extra nozzles are good for when i feel like experimenting with that. The one downside is the instructions are kinda blah, but there is tons of resources on youtube. I used the tomb of 3d prints video and my printer works like a dream

If you’re looking for your first printer (or 5th) and you’re one of those people like me who do hours of research before a purchase, let me save you the trouble. Buy this now. Then buy an SKR board, capricorn bowden tubing, and a BLtouch kit. A lot of my friends print and have Prusa printers and with some tweaking settings, this can put out prints just as good and I’ve seen people on FB who are more skilled than myself print things with absolutely mindblowing quality to the point youd think it was from a resin printer. I think this is the most common printer out there so there are dozens of Facebook and reddit groups for support. Buy it. Now. I command you. Happy printing 🙂

Works well, was a decent price, arrived well packed and I am overall happy with the purchase.

That said, the one con I have found so far is the fastener quality.

1 of the screws that hold the electronics bay (main board tray) has had the head stripped out, I was able to remove and replace it, but I feel like they could have used a better grade of fasteners without adding much if any to the cost.

I have to give 4 stars for Tech support, mainly because I haven’t had to use it, so I cannot say it is good or bad, however I would hope it would suffice.

The printer came packaged very well and a few days early ( I dont do prime). All parts were there and damage free.

They needn’t have bothered with the illustrated instructions. Seriously, toss that in the trash. Youtube is always the place to go for something like this. However, I’m vaguely aware there might be some official instructional video out there; Maybe I should have watched that but, it was just mush easier to search youtube while I waited for my packageto arrive. As a beginner, It took me about 3 hrs to build. It went pretty well but I had some issues getting the screws into the top support bar and the end. I really had to force things together there. Fortunately it didnt affect my prints.

Just FYI. I also ran into some issue with how I ran the cables. I had a few hangups while printing so be very careful nothing will snag. Cable management is a huge issue that I over looked.

Leveling the bed was another chore that required another youtube video but once you learn, it’s not that bad. I’m really glad I got the glasstop because I noticed the bottom heat bed is warped like many other reviewers have said. Fortunately, clipping the glass bed on solves that issue.

The textured surface seems to help with print adhesion but I still need to use some stick glue because once in a while a corner will peel up.

So far I have ran PLA (whistle) and TPU (watch band) filament with very good results. I am very pleased with this printer. Obviously, there are things that could be better but for the price you cant beat it. I plan to upgrade stuff as I go along but right now Im printing right out of the box with zero issues. I definitely recommend this printer to everyone. Just buy it already!

Easy to assemble and produces great quality prints once calibrated. Do your homework by watching some of the great resources on YouTube. 3D printing can be frustrating and difficult at times; upon careful inspection I usually have to accept responsibility for most of the failed prints and cannot blame the printer. What this machine is capable of doing at this price tag is nothing short of incredible.

Completely new to 3D printing and went with the Ender 3 after lots of research. I took about 2 hours to fully assembly with a few tips from YouTube. I had read other reviews and heard horror stories of filament going everywhere, projects not sticking to the mat and things going crazy in general. I honestly haven’t had a single issue in the few weeks I have been running it. My very first attempt came out perfect! Watch videos on how to level the bed, get your settings dialed in and print slow. Read the last sentence again… Endless mods can be printed or easily done to the Ender 3

Update: After I got the second unit, I was able to get it setup and functioning well. With some added TL smoothers you can purchase here on Amazon (4 of them, one for Z,Y,Z,E axis) as well as the printable extruder fan upgrade called “bullseye” on thingiverse, the print quality is amazing. Thoroughly impressed with the quality prints I’m getting – some tips for people new to the 3D printing scene, it’s still a little wild wild west like, so you have to configure everything yourself to get great prints. I would recommend watching a youtube video for building it, leveling the bed, printing upgrades for it, as well as configuring your slicer settings just right for this printer as well as the material you’ll be using (most start with PLA) wish you luck on your 3D printing journey, this is a great place to start.

Initial product that arrived:

The pictures attached are a stepper motor, in this case for the Z axis. Typically there is a piece that goes between the motor, and the attachment that seats the z axis bar (that metal bit in the picture) int his case, it could not tighten enough for the Z axis bar. This allows that metal part, to grab the motor and ultimately allows it to function correctly. In the picture showing the bottom of that metal piece, maybe had some extra wear. It made me very concerned at that point, for all I know the motor is seized. This has rendered the printer un-usable.

Update.

I would highly recommend replacing the heat bed springs as the ones fitted are useless as you will be messing around leveling the bed for every print, i have replaced my springs with the stronger yellow springs found on amazon and i have compleated 5 prints without having to messabout with leveling the bed.

Prior to owning this printer I had an M3D Mini and an RepRap Guru I3. It is difficult to put into words how much better this printer is in every way. It comes mostly assembled and most users could finish assembly within an hour. Belt tension is easy to get right. I have not had issues with filament jams and it prints circles perfectly which was a major issue with my previous printers due to belt tension. If I had one complain it would be the way that the filament holder mounts to the top rail but this is minor. No regrets.

It’s not the best printer, it’s not the worst printer. The key to these are that you can UPGRADE them, it makes it possible to end up with the same quality printer as the more expensive ones without having to spend the money all at once. Stock, it’s a decent printer, but it takes a lot of tinkering and calibrating to get things good, and even then it’s not hard to mess something up and have to go through a few steps again. With some upgrades it becomes a lot better, things like better bed springs, a metal extruder, and upgraded tubing go a long way in printer quality improvements and things like auto bed leveling and silent stepper boards being nice luxury upgrades that won’t set you back a ton.

Mine came with a hot bed and glass bed that were both pretty badly warped (and only getting worse with every print), but Comgrow was excellent at working with me and getting me a replacement on the way, despite the shipping for that turning into a bit of a nightmare but that’s not their fault! They’ve been amazing at keeping me updated on things and making sure I’m happy with things.

I haven’t gotten a ton of AWESOME prints out of it due to the bed warping, but I’ve managed to compensate enough to get some pretty decent ones, mostly upgrades for the printer, but you learn a lot about 3D printers just by building and upgrading this one. I highly recommend it for beginners, despite the technical overhead, just overcoming that provides you with invaluable experience in working with ANY 3D printer.

We bought this for my tech savvy 12 year old for Christmas and we are thrilled with it. We did a lot of research for budget friendly, user friendly, quality printers and went with this one based on reviews. My son put it together and adjusted it completely on his own in about 3-4 hours with watching some YouTube videos for some extra help. He printed the dog test piece and it was perfect! Excellent print quality. Not enough filament included to finish the test piece but enough to know it works. We bought the hatch box filament and have had great results with it.

Used Thingiverse to download files into Cura and did have to play with the temp a little after a couple of failed prints. Make sure to clean plate between uses. He thinks that’s what his problem was. Worked great after cleaning and increasing temp a little. All in all, a great printer, especially for the price!

After using this printer for a few weeks now, I can confirm that this is one of the best 3D printers for the price on the market, period. I had it assembled in less than an hour, and was printing calibration tests in less than two. I haven’t had to use Creality’s tech support yet, so I can’t comment on that but I can say that the printer has been covered extensively in several online forums, and that has been much more support than I’m assuming Creality themselves would be able to give.

The glass bed works amazingly, and gives all of my prints a solid, smooth finish on the bottom. They also come off with little to no effort, which is a big step up from other vinyl build plates like the one on the stock Ender 3.

The extra nozzles offer versatility for several different print qualities, and it saves you from having to sacrifice build quality or build time with a standard 0.4mm nozzle.

Pros:

Tempered Glass plate is 1000x better than the vinyl build plate

Extra nozzles give a great amount of versatility to the printer

Print quality is awesome

Easy to learn for beginners

Cons:

Has to be assembled, which can take a decent amount of time

With a glass bed, it can take a long amount of time to heat the bed to ABS/PETG temperatures

I would definitely recommend this to someone on the fence about buying it.

over all acceptable but has issues, a lot of problems with the hotend which i ended up replacing with an a microswiss, The boden extruder arm had a notch warn in it after a couple of months of use, took a while to figure it out and replaced with an all metal extruder drive. default build surface kept sliding during prints so replaced with a magnetic build surface. Replaced boden tube 3 times. No thermal runaway protection, No bootloader to make it easy to update marlin. No fan guard for the driver driver board.

I am a beginner but I am also an engineer. I found the assembly fun but it did take a couple hours so it is definitely not ready to print out of the box. Some adjustment was needed on the print table and the adjustment wheels were maxed out. I had to play with that for a while to get a level surface. Some complex prints have stringing but a google search revealed several setting changes which seemed to reduce the problem. Other than some stringing this has been an impressive printer…especially for the price.

The frame, parts, control box and everything feel very sturdy. There are not really any “cheap” feeling parts anywhere on this printer. I was a bit worried about the China sourcing but this seems fairly high end. There was no bottom cover for the control panel or over the fan intake (which faces up) which seemed an odd omission, but it was easy/fun to print those parts. I would characterize this printer as an advanced beginner printer and I would purchase again in a heartbeat.

The printer works great. I absolutely love it.

Pros:

* Easy to put together compared to other low cost 3d printers

* Decent print quality

* Glass bed included

* Comes with extra nozzles of various sizes for finer or quicker prints. (I’ve only used the 0.4mm nozzle so far)

* Includes scraper to remove 3d prints from bed.

* Easy to upgrade to get better prints

Cons:

* Need a little knowledge of 3d printing in order to calibrate everything to get a good print. Not so great for beginners.

* Bed springs are weak. You have to level the bed for every print. (Can be upgraded)

* Has a lot of vibration causing some ghosting

Excellent printer for the money and the seller is excellent also. I had one issue with the printer (LCD) however the seller was quick to remedy the issue and the new LCD works perfectly. The printer needs tweaking to get great prints but once set up it is awesome. I have printed a number of items, calibration cats, benchy, jointed dogs, etc. All sorts of things to adorn my desk at work 🙂

Update : 2020.01.26

I had the Y-Axis belt snap on my printer for no reason. I reached out to the seller just to see if they could help. Excellent customer service. Thank you

When(not if) I purchase another printer, I will look to Comgrow first. They have been responsive and great to work with.

I do recommend that before assembling the printer to google/youtube videos on assembly. The instructions are clear for assembly but the videos will give you pointers, tips and advice to get it tweaked while assembling.

Just got this 9/6 and I’ve had nothing but problems. In order to get it to turn on I have to wiggle the power supply plug into the box, the bed is warped and skewed, the SD card won’t read and the usb won’t link up. My pc recognizes the printer on the port but I can’t send anything to it. I’ve tried updating the Merlin FW but again I can’t connect via usb.

Overall my experience with this printer has been one fail after another and I hope the vendor will offer a resolution soon, otherwise it goes back. I gave it two stars instead of one because of the solid built.

Update: 9/13/19

Comgrow’s customer service walked through most of my issues. My power supply is faulty and they’ve offered a replacement. I am still having issues with usb connection which may mean a motherboard defect. I’ve sent pictures and video’s and am waiting on what to do with the board.

Update: 10/10/19

Comgrow kindly sent me a new power brick and it works. The motherboard issue was also resolved. I love my printer and the ability to add mods, perfect for the DIY enthusiast.

The printer arrived well packed and went together well. This is my 2nd Ender 3-X with the glass bed, both ordered through Amazon. The first one has been operating pretty much flawlessly after I got through the initial learning curve.

This one though, exhibited a rather annoying problem after initial assembly. The control panel’s selection encoder was very intermittent and many times had to be cranked MANY steps to get it to change from one item to the next. As I thought, it was the encoder that was bad, but to be safe, I ordered a new display panel from Amazon rather than go through Comgrow and wait for delivery from China and upon replacing the Display panel, everything worked like it should. Having 2 printers, I needed to have a spare display on hand anyway.

I’m an amateur radio operator and taught equipment repair in the US Army for the better part of my 20 year career and have a well stocked parts pin so, once I had the new display in place and confirmed working properly, I changed out the encoder on the bad one. Tested it in the new (and old printer to make sure) and the encoder replacement cured the problem so this board is re-installed in the printer and the spare is back in the electrostatic safe bag and stored with the other replacement parts for either printer.

Print quality on the new one is actually a bit better than the older one and the glass build plate is a joy to use. Keep it “squeaky clean” by wiping it with Isopropyl alchohol after every print and DO NOT TOUCH the bed with your fingers or body oils will keep the prints from sticking to the bed. Keep it clean and they adhere nicely with NO glue stick, hairspray or other adhesion agent necessary.

All in all it would have gotten 5 stars except for the defective encoder problem. I did NOT contact tech support over this as I considered myself capable of repairing it myself and it turned out I was correct. Therefore, I did not rate Tech Support in this review as I have had no contact with them.

I must say, although I knew id have to be putting the printer together, I didn’t quite realize how involved it was going to be. My advice for any other non-experts out there is to just take it slow, and for gosh sakes don’t try to build it from the insufficient 1 page sheet they supply… look to YouTube and youll be fine. Highly recommend Tomb of 3D printing Horrors video… I followed it (slowly) and was running in no time.

So, my printer came with a stripped leveling wheel. I contacted Comgrow and honestly was not expecting much besides a stock reply, but Cathy from Comgrow was awesome. She asked me to buy a new wheel and then refunded my Amazon account the price of the item, and even sent me free filament as a thank you, and continued to follow up with me (unprompted) for a week, to make sure all is well.

Comgrow, give Cathy a raise, and if all of your employees are as good as her, then give yourself a pat on the back as well.

Anyway, the printer is built, and im printing some great things…. overall very positive experience.

Pros –

Great boxing, well packaged and although the box was a bit scuffed up, the printer itself seems undamaged

I enjoy a good diy setup so the excitement of putting it together is part of the thrill

Edit- after returning the printer that didn’t have the retention screw or the 5 nozzles, the new printer came back perfectly functional and with an added bonus! Comgrow emailed me a discount code for the hassle so I could get filament at a much more affordable price. So now I have a fully functioning printer and will soon have several kg’s of filament to print in multiple colors.

Cons –

Didn’t come with the 5 free nozzle ends that it said it would in the description

Edit – After attempting to Assemble the printer, one of the screws required to secure the vertical rod into place was missing, rendering the Printer useless

Although these cons held true on the first purchase, comgrow made it right by expediting the new printer shipment and providing an Amazon discount code for filament.

It worked ok for a couple weeks but ever since it has a been a constant struggle with under extrusion. I replaced the M6 fittings, reset the ptfe bowden tube (mulitple times), then replaced it, and cleaned and then replaced the extruder gear. I get nice clean lines when I push the filament manually. Finally got it squared away. The Creality glass bed isn’t perfectly flat! When the nozzle encounters a high point (about the quarter-size near the center) the filament clogs and everything goes to poop. Printing rafts seems to fix this, but I wish I didn’t have to. Glass should be flat.

UPDATE: Comgrow sent me a new glass plate, even though it wasn’t their fault it had an imperfection. Thanks!

UPDATE: Seller reached out to me and offered to send a replacement glass bed. Thanks.

The packaging is great (tools and extra parts provided), but on to the elephant in the room: assembly and initial calibration/parameter setting. It took me approximately 4 to 4.5 hours from opening the box to my first successful print. Here is what I can tell you about that process:

1) TAKE YOUR TIME – The more careful and meticulous you are in this process, the better things go later. I think the reason I had such great success on my first attempt using the printer was due to me taking so long during the set up. I had some moments of frustration, but it really isn’t that bad. This is a ~$200 3d printer with the quality and build size of printers that cost 2-3x+. The long initial setup and calibration is well worth it.

2) Use multiple sources during set-up – I used the 1 page instructions included, the instruction booklet which can be downloaded here (https://www.creality3d.cn/download/product-file_c0002), and, MOST IMPORTANTLY, this awesome guy’s youtube video for the assembly (https://youtu.be/me8Qrwh907Q) and bed leveling (https://youtu.be/5eqTmb01cBk). A little over halfway through the assembly process I gave up on the manual and just carefully watched and re-watched the youtube video steps, cross-referencing with the manual once major steps were completed. LISTEN to this guy when he tells you to take your time! Examples include: ensuring the two main z-direction aluminum posts are equidistant at the top and bottom (bolt tightening trick), tuning the eccentric nuts on the 3-wheel rail sliding assemblies, bed leveling, and more. These small tuning steps during the assembly fix most all problems people have.

3) RELAX and realize this isn’t an out-of-the-box ready to go 3d printer. It, like all 3d printers, need some tuning and a bit of experimentation/experience to achieve the printer’s full potential. For example, the included test print was a smashing success, but my next, custom print didn’t turn out as well. It didn’t adhere to the bed after several layers and also was a tiny bit stringy in sections. I fixed the adhesion by telling it to print the object with a brim (layer under the object) and also turning on “Z hop when retracted” in case the nozzle was bumping something while it was moving between print areas (this option is in Cura, the slicing software – more about that below). I fixed the stringiness by turning down the nozzle temp about 8-10 degrees.

4) If you’re having an issue, it’s likely that 10 other people have asked about it online. Do some google-fu. This may be the most important part of successful 3d printing. There are SO many great sources and communities out there to help fix issues and speed up your progress.

What software does this thing use!? Ok, well I didn’t know jack crap about any of this a week ago, but here is what I’ve learned since. This printer uses g-code files when printing. G-code is a file that tells it where to go (x,y,z), what layer height to use, what printing speed to use, etc. G-code is generated by slicing software from a 3d model (usually a STL file). You can download Ultimaker Cura for FREE here (https://ultimaker.com/en/products/ultimaker-cura-software). In Cura, you can change all the parameters for your 3d printer easily (layer height, wall thickness, infill density, nozzle temperature, build plate temperature, support and adhesion structures, etc). Cura now has the Ender 3 as a printer option.

The easiest way to get to 3d printing some cool stuff is to go over to a free 3d model website such as thingiverse (https://www.thingiverse.com/). Download the files for whatever you want to print. Open Cura. Drag and drop the stl file(s) of the object(s) you want to print into Cura. Adjust the aforementioned settings (layer height, speed, etc). Click the “slice” button at the bottom right. At this point I like to hit the “preview” button and drag the slider on the right up and down to look at how the printer will print the object. Once you’re satisfied, select “save to file”, save it on the micro-sd card, put the card in the printer, and you’re ready to go.

If you want to customize objects (outside of simple scaling and such) or make your own from scratch, god speed to you. It’s a helluva learning curve, but that’s what I’m working on now. I’ve heard Blender is a pretty good, free 3d modeling software (https://www.blender.org/). Most any 3d modeling software allows exporting to a .stl file

Overall, I have to say that my expectations for this product were greatly exceeded. If you have a bit of patience and a willingness or ability to use google-fu to figure some things out, this 3d printer is amazing in both build quality and ease of use (once it’s set up). If you don’t, well I guess you’ll need to shell out 5x+ the price

I bought this machine to introduce myself to 3D printing, and after a couple weeks of use, I am very happy with my purchase.

I was able to build the machine (using only the included tools) and achieve functional printing of the included gcodes within 2 1/2 hours of opening the box. I appreciated the fact that the printer shipped with all of the tools needed to not only build the machine (allen keys and wrenches), but also tools commonly needed for printing (scraper and clippers). The included tools are a mixed bag in terms of quality. The clippers are quite nice, and will see quite a bit of use in the future. The allen keys and scraper are perfectly fine/middle of the road. The included wrenches are pretty cheap though; having a set of small crescent wrenches available would be a good idea for construction and maintenance of the printer. As a whole, the machine feels very sturdy, and I have been able to pick it up and move it from room to room without a change in print quality or the need to re-calibrate anything. I have heard that the included filament isn’t enough to finish printing some/any of the projects included on the SD card, which is a bit of a bummer. I only did a small portion of the included dog print job before cancelling the job, so I can’t say for sure if there would have been enough filament or not.

I had looked around at several versions of the Ender 3, but decided to go with the Comgrow. I chose the Comgrow package due to the inclusion of the glass bed (which mitigates many of the adhesion issues of warped print beds that I have read about in other Ender 3 reviews). I add a touch of hairspray after leveling the heated bed every few prints, and have no adhesion issues. The additional print heads are nice as well, but I haven’t printed enough to need to get into them.

I am enjoying this printer, and recommend it to anyone interested in getting into 3D printing.

Ender 3 printer works great. I would recommend watching the youtube videos before and during the assembly. The instructions that come with the printer are on a two-sided single sheet in picture format. They are great for finding out which screws should be used at which step but don’t cover things that will make the printing experience better. For example, there are no instruction on how to align the uprights or the cross arm. Youtube is filled with videos on how to adjust everything so its aligned properly. Without the youtube videos I doubt I would have figured out the alignment issues I would have had until it was too late.

I have had no issues printing all kinds of stuff. Using Fedora, FreeCAD, and Cura, I’ve been able to create my own designs and print them out. I can’t believe the quality of the output for the price. The learning curve was a little steep at first but now that I’ve figure out how to make my own stuff printing it out is a breeze and fun to do. Just have a little patience and take your time setting things up and you’ll enjoy the Ender 3 printer.

First off instructions could be a bit more clear using actual pictures or just better illustrations. I’m generally very good at diy stuff so if I struggle a bit with something I can imagine the average person would have worse luck. The only other complaint I have is the bed. Don’t bother with it. Get a nice glass build plate and save yourself the hassle of trying to level a warped bed and thinking you need a BL touch or other autoleveling solution. I also imagine it wouldn’t cost THAT much more to include a cheap all metal hotend but for $200 you can’t have it all. Overall a great printer for the money, just know you’ll be spending more money upgrading it VERY soon.

Update: I’ve read you don’t need TL smoothers on the newer pcb (v1.1.3 specifically) but mine shipped with a v1.1.4 board and I got salmon skin on my prints which was thankfully fixed by added TL smoothers. yet another instance creality cheaped out where they really didn’t have to

TLDR: works well but held back by needlessly bad components, expect to upgrade parts if you want to do any serious printing

When I originally ordered this, I thought it was an Ender 3X because that’s what it said in the “Product Information” section. When I reached out to Comgrow about this, I didn’t get a reply, I became concerned that I had been scammed (which is why my previous review was negative). I have since been in touch with Comgrow (they were observing the Chinese New Year holiday), and they have been more than willing to clear up this issue. They said they are working to update the product information on this item, but haven’t been able to as of yet. They said that they don’t have anymore Ender 3X’s, so this is a base model Ender 3. I haven’t had a chance to print with mine yet, but based on their customer service so far, I am not concerned about any future issues I might encounter, because so far they have shown that they genuinely care about their customers.

This was my first 3d printer kit that I had to assemble and level. I do have a delta so I knew what to look for in getting a printer operating well.

Putting it together took just under 2 hours while watching a movie. I used a folded piece of paper and my eyes to level the bed and had it printing the test print in less than 5 minutes.

The test print seemed long for the time of day and I didn’t want to leave the printer running on its first print unattended overnight.

Unloading the test pla was easy. And I loaded the printer with ABS. The printer took 5 or so minutes to get to 110 celcius. The first layer of ABS stuck on the magnetic bed very well. The print looked spectacular and currently in use as a functional piece. The print looks identicle to my $1000 printers product.

I will push this printer and see how it runs in a year or 2.

At this point I am very happy.

I ordered this printer for my graduate research. The printer arrived with some defects including some broken wire terminals which was frustrating. Customer service was quick to replace those, which was a comfort. The instructions tell you to put the Z end stop at a certain position but this was causing issues with bed leveling so I had to adjust it. The bed was also wobbly and required some adjusting, and the rollers are not perfectly smooth. Overall it took about 3 days to set up the printer, mostly because I had to solder the new wires in for the broken ones (the original wires are glued into the motherboard and not easily replaceable).

All that said, the printer is now printing away with no problems so far. Although there were some quality issues initially, causing the setup process to be a little frustrating, it appears to be a solid printer for a cheap price which is what I was looking for. I give the assembly process a 2 but for the price I give the printer a 4.

The printer was exactly as described, came with no shipping damage or missing parts. I have ran many 8+ hour prints since receiving it and it just performs without error. The only thing I have experienced is the warped bed. I was able to print quickly as I noticed the bed deviation during a level test and I installed the included glass bed to “correct” this issue and continue my prints. The the yellow connector for the heat bed does not get warm at all so that problem seems to have been corrected by the manufacturer, I did receive the silicone sock aswell. One thing I would like to note is that the standard ender 3 has a steel Z-Axis bearing which is non adjustable, this one, the Pro has a brass bearing which is superior. It operates more smoothly and it is adjustable by a few millimeters so BIG plus that has not been mentioned at all but should be as it is a big improvement regarding the spacers needed to correct the Z Motor positioning on the Standard version and not needed here. I look forward to purchasing the Ender 5 and seeing if any of these changes in the Pro carry over and if a Pro version were to be released I would gladly purchase it aswell.

We spent about 2-3 hours building the 3D printer out of the box. We followed the reviews and combined youtube instruction videos with the instructions that cone with it. I highly recommend doing this as the picture instructions dont identify a lot of aspects that are important.

We also ran into an issue of no instructions on leveling the bed, feeding filament, or really anything post build. Again, highly recommend youtube.

We spent several hours attempting to get the printer aligned and printing good. One thing I can say is that if you are expecting to put it together and it print perfect right away, thibk again. 3D printing is an art of constantly tweaking and adjusting the project.

We are still working on it but getting there. One issue I did have is one of the allen screws heads (that is preinstalled) came to me stripped too much to loosen with the provided allen wrench. This prevents me from changing the nozzle easily. Ill have to replace the screw once Im able to get it off.

UPDATE: Comgrow contacted me following this review at 3 Stars and have been very helpful in getting this part issue fixed. Through a few emails we have determined the best way to fix it and get it in working order. I am updating this to a 4 star review. The obly reason I have not given it a 5 is due to the poor instructions.

I will start by saying I had a bent x-axis rail. Cromgrow gave 5 star customer service and sent me a replacement rail. Since then, I have printed a few things and I’m very impressed with the print quality and quality of the unit. I went from an M3d which was difficult to use, had a small print space and required a computer to be hooked up at all times. This machine blows that one out of the water. Seriously, without tuning and right out of the box my prints were looking better. With some fine tuning I’m sure this will be printing some high quality parts. I attached a picture of my first print which is a tolerance test. This is literally out of the box and performed great, extra tuning will get me to a tigger tolerance. Keep an eye out for cura printer profiles that others have used.

To start with, don’t expect this printer to only take a few hours to get it ready to go. While it may only take that long if you’re lucky, or have previous experience, if you’re anything like me and a complete novice to this style of printer it’s going to take you some time. Especially if the things that are pre-assembled come unlevel or need some troubleshooting.

That being said this is honestly the best 3D printer hands down for its size, quality, and the fact that it does come halfway assembled. If nothing else I think the struggles putting it together and tuning it has taught me more about 3D printing than my job has (and I work in CAD with high end 3D printers). My best advice is to research research research. Find all the tips people have found on setting this up right the first time so you can move on to the possibilities it opens up!

It prints great, the included bed surface actually works really well for me, and it’s a great budget printer to throw yourself into 3D printing with.

After hearing tons of positive things about this printer, I decided to buy it to replace my Anet A8. Remembering how important it is to make sure things are connected and tightened properly (thank you, Anet A8!) it took me about 3-4 hours to build it. The instruction pamphlet that came with the printer were decent, but I had trouble installing the X axis part so I decided to watch a youtube video to help me out. Apart from this hiccup, the build process wasnt difficult at all. 5/5

Why did I knock off a star, you might ask? First, the printer was wobbling, like a four legged chair with one leg that was shorter than the others. This might be due to me not tightening the base properly, so take that with a grain of salt. The big issue was with the heated bed, it would not heat up at all. I opened up the control box and made sure that the wires were properly connected (they were). I followed the train of wires to the heated bed and saw that they were connected fine. I contacted support and they asked me to use a multimeter to check the connections. Doing so revealed that 24v was entering the heated bed, so there was most likely something wrong with the board itself. I contacted amazon and they sent me a replacement under the condition that I send the faulty one back within 30 days. It arrived in two days (Thanks Amazon!)

I rebuilt the second printer in about an hour, since I was already familiar with the process. To my delight, the heated bed worked as intended, and there was not any wobbling (really think I didnt tighten the base properly on the first printer!). I started leveling the bed for the first print, and to my dismay one of the wheels used to tighten the bed was broken. Thankfully, I still had not shipped out the first printer so I just swapped the broken wheel with one in that printer. After that, I did not have any mechanical issues.

The printer printed the test print extremely well, as well as everything I’ve thrown at it. Comparing it to my Anet A8, its amazing how little work I needed to do to make it print extremely well. If the issues that I faced were a nonfactor, I would recommend this as somebodies first 3D printer. The setup process is very hard to get wrong, and slicing software like Cura is pretty simple to use.

TL;DR Faced some issues with the heated bed and leveling wheel, amazon sent a replacement which works fine. I would recommend this as someones first printer, but make sure you read the instructions carefully and dont be afraid to watch youtube videos

from Amazon Logistics dropping at my house to starting first print, 2 1/2 hours. this was a relatively simple assembly, good pictures for reference, all screws and parts are in individual labeled bags which is a tremendous help. all tools needed were provided as well this seems to be a sturdy and well designed product. some adjustments will need to be made.

only had one problem. one lead to the thermistor on the hot end broke during first print, causing a mintemp error.

i was able to remove the metal shield and re-solder the connection. it may have been that the original soldered connection was too close to a hot part and simply ‘un-soldered’. all good now.

3D printing is still at the stage where some mechanical/electrical/software skills are needed.

as of this writing 24-nov-2018 i do recommend this product for adults and older teens who have nerd skills.

not a plug and play toy.

It came in a couple days thanks to Amazons incredible shipping and I had it set up and running in about 75 minutes. I had previously watched a YouTube video so I had an understanding of what went where which made the flimsy instructions all I needed. But before I tried to print I found another video for this printer regarding fine tuning and printing which really helped to dial it in.

I still have a learning curve to improve my prints and designs, and am still having occasional failures, but they aren’t the fault of the printer. The materials seem like a good quality, alignment,holes, threads were all clean, but it’s clearly a basic printer and you can easily get sucked into the world of ‘upgrades and add ons’ making this price point higher. I’ve so far stayed away from those temptations knowing that if I need something better the ill but something better. You can put spoilers, wheels and a ten thousand dollar paint job on a Hundai, but it’s still a Hundai. Nothing wrong if that’s your preference, just be aware that any extra money you pour into a printer in this price range may be better spent on a better quality base model.

I am using tinkercad on the web for modeling and Ultimaker Cura as my slicer, both free, and so far meeting my fairly simplistic needs.

The bottom line is that for this price point I am able to fairly quickly create prototypes, dial in my design, and spit out a decent final product… all in my first few days. If I eventually get bored of 3d printing I’m not out a lot of cash. If it meets my needs I saved a lot of bucks. If I find I need something more it was still a great entry level training platform. So far this has been the perfect choice and you shouldn’t hesitate to give it a try yourself.

The Ender 3X is my second 3D printer. The first was much more basic than this one and could only print with a limited number of materials. I grew bored of it quickly and haven’t touched it for 3-years so I am very much still a newbie at this.

Enter the Ender 3X. It arrived in a very well packaged box and the components appeared to be of a much higher quality than the price would suggest. Assembly was a breeze thanks to a well illustrated manual; although a couple of steps were missing the required screws in the printed version, they were listed on the PDF version on the included SD card.

The quick start guide was easy to follow and after a couple of attempts I was able to print the test dog model included on the SD card which took about 5-6 hours. One thing I learned very quickly is that washable glue stick is a must when using the glass bed. Not only does it help the model stick, it can easily be washed off with water once cooled!

I’ve had the printer less than a week and only printed with PLA so far, but I have several spools of ABS and TPU to experiment with as I learn to use this wonderful printer more effectively. It is a bit noisy but a quick online search revealed several aftermarket parts to help with the noise as well as the performance, and many can be printed!

From the perspective of someone who is relatively new to this hobby all I can say is this seems to be an excellent value for the money and I couldn’t be more pleased with my decision. It gets five stars in my book!

This is my first 3d printer and it is truly awesome. The printer has a usb port in the front and was very easy to set up an online OctoPrint server so I could send gcode files to the printer remotely without messing with the sdcard. All the design docs, schematics and the custom marlin firmware were made open source on GitHub. This is a great printer for beginners and for people with some engineering background. There are a couple of Youtube videos of people showing how to compile and flash new firmware, as well as adding new features like automatic mesh bed leveling.

I had an issue and the company offered to replace my power supply, but that turned out not to be necessary.

I’m still learning to print in ABS, so I can’t really judge the printer by the quality of my prints. The printer itself is solidly built, uses no 3d printed parts, is mostly metal and hasn’t clogged yet after 2 weeks of near continuous use.

The only problem I have is that this printer doesn’t have thermal runaway protection. I intentionally disconnected the temperature sensor after setting a target temperature. The hot-end temperature started rising. I don’t know how high it would have gone with the fans blowing on it, but I don’t like the possibility that it could start a fire.

The standard advice applies. DONT run this printer where flammable items might fall on it (obviously). The thermistor is glued in, and the wires to it are wrapped in protection, I really don’t think its likely that the termistor could come unplugged, but it would have been a simple software fix to shut off the printer if the temperature reads 0. There are some firmware updates that do this.

Start out with a good quality PLA filament. Next, calibrate the filament extrusion — there are many instruction and videos of how to do this. Mine was slightly over extruding and my factor was 93.0%. This setting resulted in the test piece walls being on average 0.0035 mm thicker of the commanded wall thickness.

These previous tests get you to a spot where you have a good working operating system (there’s still more to do). Print out the various test pieces from Thingiverse to gage your best head temperature (stock 200C was fine for me), retraction length (mine was 4-5mm), print speed limits (this will depend on layer height), and your overhang angles where you need supports (mine was about 65 degrees). Again, much info and videos out there on this.

I recommend to print out several things from Thingiverse: control box fan cover to prevent filament from dropping into your fan, a bearing based filament guide for the extruder, a filament guide for the filament coming from the spool, and filament spool bearings (these use soft air BBs for the balls). You can also print out a rear left corner wedge that prevents the bed heater cable from getting caught on the edge of the extruded aluminum.

Nice to haves: micro SD card to SD card converter and print out a holder for it. I wanted the machine to be quiet so I installed the stepper dampeners in the beginning. The damper for the y-axis stepper will allow the stepper to this the base when it goes fully to the rear — you’ll need to print out a y-axis switch relocator from Thingiverse.

I did a before and after with the benchy boat to see the impact of the diode boards for the steppers and it helped with the salmon finish (the salmon surface was not too bad to start with but the diode boards were already in so I left them in).