ANYCUBIC Wash and Cure 2.0 Machine for LCD/DLP/SLA Resin 3D

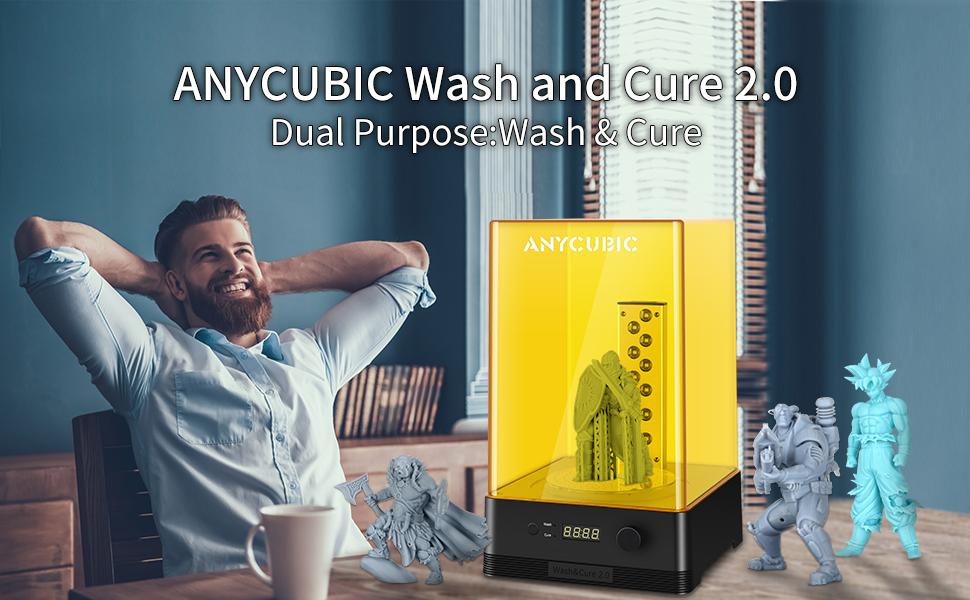

ANYCUBIC Wash and Cure 2.0 Machine for LCD/DLP/SLA Resin 3D Printing Models, 2 in 1 Wash and Cure Station, UV Resin Washing Bucket and UV Curing Dryer with Rotary Curing Turntable

| Weight: | 3.7 kg |

| Size: | Wash and Cure 2.0 |

| Dimensions: | 22.5 x 23.5 x 36.5 cm; 3.7 Kilograms |

| Model: | Wash and Cure 2.0 |

| Part: | UK-WS2A0BK |

| Colour: | Yellow |

| Pack Quantity: | 1 |

| Batteries Required: | No |

| Batteries Included: | No |

| Manufacture: | ANYCUBIC |

| Dimensions: | 22.5 x 23.5 x 36.5 cm; 3.7 Kilograms |

| Quantity: | 1 |

| Size: | Wash and Cure 2.0 |

I’m a hobbyist at resin printing. This means when I make a little time to try printing, I need it to be easy and fuss-free.

In the photo is a previous typical attempt, with inadequate washing in a plastic pot, a toothbrush, and paper towel drying, before a UV nail lamp to cure.

Pictured on the supports is the output from this machine. 3 minutes wash (after a 1 minute pre-rinse in some dirty IPA), air dry and then 3 minutes cure. Really clean results without any hassle.

I thought my occasional use meant I couldn’t justify this machine, when the opposite is really the case.

I use an Elegoo Mars printer. I chose the Anycubic wash machine because their online articles are very clear and I prefer the knob control to the touch buttons of the Elegoo version. I expect they work the same.

Bought this for my son for Christmas as an introduction into 3d printing. Worked flawlessly and seemed to take the hassle out of cleaning and curing our prints. The time required to both clean and cure was a bit vague so required some searching on the Internet but we’ve settled on around 4 minutes for each process which seems to work fine. Overall, really happy with the product and a lot cheaper than other brands.

This is the wash and cure machine to make your models cure nicely and sturdy.

Sorry for the late review but it was only opened on Christmas day and already y son has put together a model as he was bought both kits from amazon.

He’s over the moon with it. I can honestly say I think it’s awsome too and would highly recommend it. Buying over instalments on these high quality machines makes things a lot easier too.

for 100 the spinning thing is really weak but better than nothing i guess

Brought as a present for my son he will love i

Having just brought a resin printer I tried manually washing the first model and thought “there must be an easier way to do this” so looked around and found this.

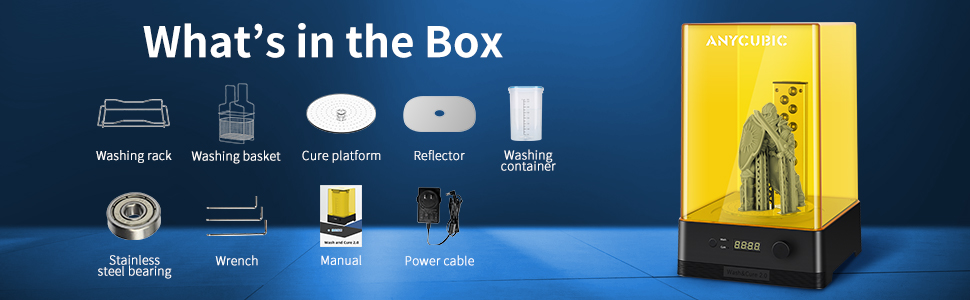

Using it is very easy – although you really need more than a single litre of cleaning fluid and I ended up buying another couple of litres (I’ve only used about 1/2 a litre extra and will use the additional as topups or as a change). Add the fluid into the plastic cleaning container, put the model into the basket and then put the basket into the container, set the timer (I’ve used between 5 and 10 minutes for my models so far) and start the machine. It can be a little noisy as the impeller on the bottom of the container rotates but it’s not so loud that I can’t be working in the same room.

Once the model has been cleaned lift it out and let it drip dry/evaporate, then take the container off the unit and put the reflective strip and curing disc onto the bottom of the machine, place the model on that and cover it with the yellow cover, set the timer and turn it on.

A word of warning, make sure that the wash container is sealed when you are not adding or removing a model – IPA is flamable.

I purchased an Anycubic Photon printer and it was suggested that I get a cure/wash machine to go with it as it will save me time and headaches. Okay, so this one seemed reasonable with the turntable and I ordered it at the same time as the printer.

You will need to buy some Isopropyl Alcohol with this as it is needed for the resin wash (unless you get water washable resin.) The bucket will take around 2.5 litres to get up to the tray rest on the metal basket, but this can vary depending on what you are washing.

The one thing that surprised me is that it doesn’t take long to wash and cure a model. I was expecting to have to leave this switched on for several hours for it to do it’s job. Not the case at all. In fact, most of the time for relatively small models you’re only looking at around 10 to 15 minutes for each cycle. I don’t why I got the impression it took longer, but there you go, assumptions and all that.

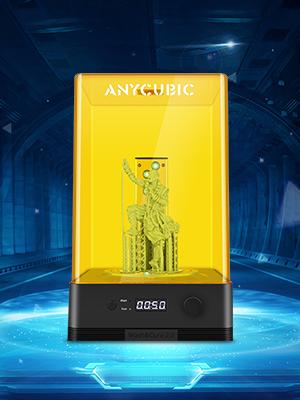

Build quality is excellent. Everything is finished off nicely and there are no rough edges, burrs or ridges that I was able to find. The controls are simple. A button to select wash or cure, and a dial to select how much time you want the cycle to last, finally pressing the dial sets the cycle off. Power connection and on/off switches are to the back of the unit

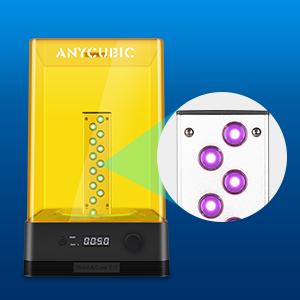

You get two different items for washes, a basket for large models and a frame for smaller ones, these are both chromed metal. The bucket is a good quality plastic and has a clip down lid to prevent accidental spillage and splashes. The turntable is plastic and a mirror sheet is provided to reflect the LED up under the model to cure lower surfaces. The models I have printed so far have all averaged around 10 minutes wash and curing each. So, very little time. The wash is surprisingly noisy with a rather musical acceleration and deceleration from the agitator. Light curing is pretty much silent and the turntable rotates quietly. Light bleed is cut down by the transparent yellow cover, but you still don’t want to be staring at the LEDs.

The unit needs to be standing on a firm level surface so that wobble or lateral movement is minimised. Some care must be taken of course when pouring in and removing the isopropyl alcohol, and while the odour is not over-powering it is best to use this in a well ventilated area. Make sure the lid is fixed properly during use and when standing idle as this will help prevent accidental spillage. Also, make sure you remove the mirror plate and turntable when using the wash bucket. The bucket sits in it’s own recess in the machine and the agitator needs to be in close proximity to the magnets below.

I was happily surprised to discover that washing and curing models only takes a small amount of time and even more pleased when I found out how quiet this unit is.

Very pleased with this purchase, it sits nicely with and matches the Anycubic Photon 4K printer I got with this, and the two units don’t take up as much space as I expected. In fact, the two together have a smaller footprint than my CReality FDM printer. They are also both quieter and faster.

Good quality, great results and a decent price. No complaints from me about this purchase. I’m very happy with both this and the resin printer.

This is a great but if kit for helping you to clean and cure your resin miniatures.

I originally tried to clean my prints with my cheap ultrasonic cleaner and small UV light and the results were terrible.

After buying this I couldn’t believe how easy it is to get perfect results!!

After a 5 minute clean and 5 minute cure my print results are now exactly how I want them.

I am using this with a Phrozen mini 4K and the build plate fits perfectly into the cage which means that gets cleaned at the same time as the prints!!

Love i

Useful addition to resin printing wash and cure easy to do with this.

Saves so much time, mess and waste, and takes up very little room in my workshop. Love it.

Vave used it for months alongside sovol Magnetic Plate and VAT. Plus keep the polysterene packing as its useful for keeping out light and maintaining temperature inside a cold shed. I mainly print 120mm Marvel and DC figures and the resolution is good at 0.05mm but takes a long time to print. Still worthwhile. Recommend Lychee instead of prioprietory software to create 3D Prints.

I am using this wash with my Phrozen Sonic Mini 4K. It enabled me to set up a streamlined workflow and minimise the odour and mess whilst 3D printing in the spare bedroom. I have found that the Sonic mini 4K build platform fits snugly at top of the wash basket.

The wash tank needs to be filled with 2.5 litres of IPA to work as intended even when washing low height models.

I bought this for my son, it works really well for him. The only complaint he has is the print board won’t fit in. so you have to take what you have printed off the board before you can wash them.

I have been using this wash and cure station and it has resulted in a lot of isopropanol contaminated with unused resin.

And of course, you want to try and re-use that solvent.

The first step must be to convert the resin in solution into solid particles, so of course you set the washing container in the machine and set it to cure. This UV exposes any remaining resin turning into small solid particles.

Now to remove them… gravity filtration doesn’t work, it clogs up far too quickly. Adding a vacuum simple accelerates this process and pulls through particles.

My next thought was a distillation to recover the solvent but who has a flask big enough, or wants to risk heating up 3L of flammable liquid?!?!

We could do this via a change of pressure, but that means building a whole new machine and then I realise….

…I already have the answer to this problem because I also brew my own wines and beers.

The problem is to remove fine particles from alcohol, in home brewing we call this process “fining”.

I have experimented with multiple fining agents to remove cured resin particles from isopropanol used for washing.

I have found that the traditional isinglass/chitosan/glycerine methods work, some detergents also work but they also contaminate the resulting IPA.

By far the best thing I have found to remove cured resin particles from your washing solvent is, egg whites.

Simply take your used dirty solvent, still in the washing container and run it on cure mode for an hour to solidify the resin.

Then, crack and separate six eggs and add the whites to the solvent. (what to do with the yolks? I dunno, bake yourself some cookies or something).

Now run the container on wash mode for ten minutes to mix it all up and just wait.

The egg whites will coagulate all of the particles which you created during the curing step and this whole mess will sink to the bottom leaving you with a lovely layer of clean solvent which can be drawn off.

The remaining mess at the bottom can then be gravity filtered without clogging the filter because it is already bunched up into larger particles.

This removes the used resin from your cleaning solvent, enabling you to re-use the solvent for further cleaning.

I have used a small variety of resin printers and cleaning methods, My most common method is using two tubs filled with ipa. I would put the print onto the basket and rinse in the first tub then let the prints dry, after that I would transfer them to the second tub and rinse. As you can tell this is a long and messy process, The ANYCUBIC Wash and Cure 2.0 Dryer Machine solves these issues. It is also very quiet especially when compared to a sonic bath that we tried for a while and cleans the parts perfectly.

This machine is lightweight but robust, just like their printers the wash and cure machine is very well built and not made of plastic like most other products on the market but still remains lightweight.

As for operating the wash and cure 2.0 machine it couldn’t be any simpler, the controls consist of 1 button for selecting the mode (Wash or cure) which has indicator lights to tell you what mode is selected. The right of the front timer display there is a knob/button that selects the desired time when turned and starts/stops the machine when pressed. This machine is super safe there is no chance of leaking ipa out of the container through a seal because it uses magnets to spin the metal agitator on the bottom of the tank making the container a fully sealed unit that can be removed at any time. When in curing mode the machine stops operating if the cover is removed which is a great feature to protect your eyes.

I have placed the Wash and Cure Machine on a shelf at chest height which is not ideal due to the height. I would recommend keeping it at around hip height to make changing the tub over for the turntable easier and also for making it easier to remove the basket as well.

I personally use IPA when rinsing and put parts in for around 15 mins and then rinse off with water, whilst the part drip dries i prep the turntable for curing the part which i put on for 5 minutes.

This machine fits in well with the 6 anycubic photons i have and will be worked hard over its lifetime. The design looks great and even the colour scheme fits in well all round 10/10 for me.

I’ve been resin printing now for almost three years, and I have tried most options available when it comes to cleaning and curing resin prints a lot are messy and a lot take up a lot of space. Not the Anycubic Wash and Cure 2.0.

The Wash and Cure V2.0 is by far my favourite method so far its quick, simple and clean to use. Before i was using a 3L ultrasonic and a UV nail lamp box and although they gave good results they didn’t have the convenience and cleanliness of the Wash and Cure V2.0.

The construction seems solid with a metal base plate rather than plastic. The UV array works well with a decent cure speed while also having a turntable rotate at a decent speed with no stuttering. Resulting in a nice even cure across the model with very little effort from the user. Its also roughly the same size as Photon so doesn’t fill up your workspace.

The cure container is large enough to fit the build plate with a full height print attached but can also be used with the basket provided for loose prints if required/wanted. It has a secure sealed lid also to prevent spills and evaporation of your cleaning agent. To cure on the plate you will require roughly 3.5L of your chosen cleaning agent (personally I use Isopropyl Alcohol).

Models I’ve cleaned so far have no signs of white residue, glossy patches or sticky patches and I’ve been using a wash time of 15mins and cure time of 4 mins (wash time could probably be reduced but I’m in no rush and prefer to make sure they are clean)

Controls are really simple and effective. 1 button to swap between wash and cure and a dial to alter time and start the cycle off.

Overall I was sceptical coming in to this product but have been blown away by the ease and cleanliness of the process and the quality of the product Anycubic has produced. It is easily the best post processing solution I’ve used and well worth the price tag even at full RRP. Don’t waste your money buying all the others just buy one of these and be happy with the mess free simple process.