BIGTREETECH Octopus V1.1 for CR10 Ender 3 3D printer Control

BIGTREETECH Octopus V1.1 for CR10 Ender 3 3D printer Control Board Upgrade Spider motherboard Marlin 2.0 Klipper Support TMC2209 TMC2208 TMC2130, TFT35 E3 V3.0, TFT35 V3.0, 12864LCD ec

| Dimensions: | 19.8 x 12.9 x 4.2 cm; 310 Grams |

| Batteries Required: | No |

| Dimensions: | 19.8 x 12.9 x 4.2 cm; 310 Grams |

| Reference: | ZZB000540-KINGPRINTt |

Excellent compatibility with my Ender 5 plus printer and a stress free install with online help from “Github” and Youtube videos, it vastly improves the printer with so many different upgrade options available on one board plus the added benefit of having the Raspberry pi and TFT screen on board too so you can run Octoprint etc. I am thoroughly pleased with this package and i highly recomend it.

I bought the Octopus V1.1 to install in my Creality Ender 5 plus to allow better control of the z-axis with independent controlled stepper motors but was more impressed with the additional features of this board while installing the unit.

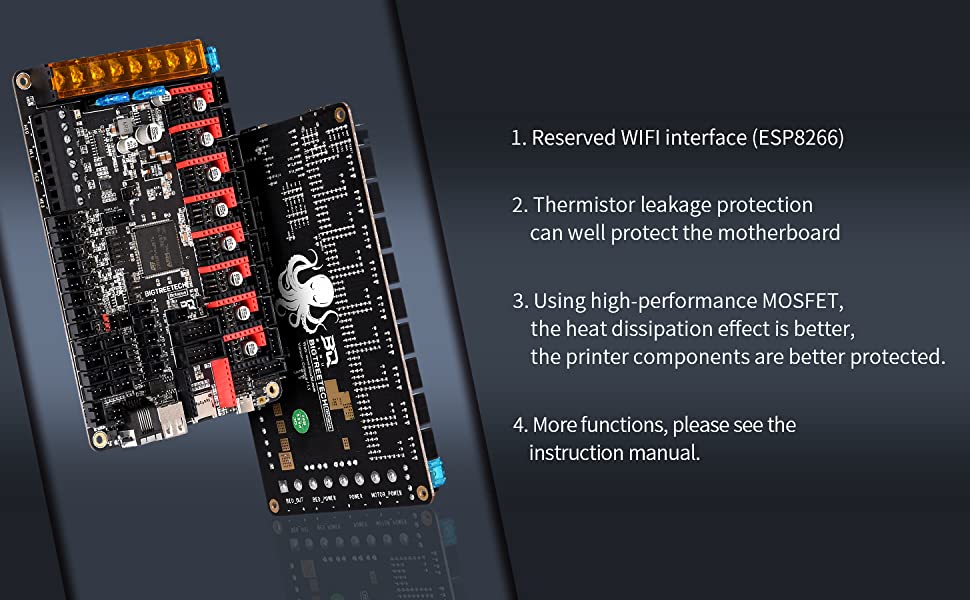

This board can control up to 8 stepper motors though I am currently using only 5, but this allows me to add additional functionality and features over the lifespan of the printer. This board needs additional hardware to be purchased to allow its operation. It requires stepper motor drivers to be purchased and installed to allow stepper motors to operate. There are various models of stepper motor drivers available that are compatible with the controller with the ability to mix and match which stepper motor driver you install depending on what size stepper motor you wish to control and what features you are looking for to give optimal performance. I purchased TMC2209 stepper motor drivers as these give good all round performance especially being classed as “silent” while in operation.

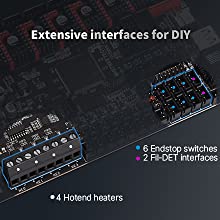

The Octopus V1.1 provides numerous options to connect multiple endstop switches plus voltage selectable fans outputs (via jumpers – 5v, 12v, 24v) on the control board that are controllable via software. The ability to select the output voltage for a fan allows different fans to be installed and is extremely useful as you can choose the best quality fans without having to deal with dropping the voltage from 24v to 12v for them to operate properly.

The full list of features just keeps going and will allowed me to adapt and add features to the printer with no worries with compatibility.

I run Klipper firmware and the installation with the information available through the manufacturer – BigTreeTech allowed me to get the printer operational in a few hours and is paired with a RaspberryPi 4b with Mainsail web interface.

I don’t have a screen installed onto the mainboard yet, but may do later if I feel I need direct control of the printer, but the web interface is sufficient to get the most out of the Octopus mainboard and the printer as a whole.

I would definitely recommend this board when upgrading your 3d printer, especially if you plan to increase functionality in the future.

I found this board really easy to install and setup Klipper on my diy 3d printer. It has all the features I need and at a good price.

This is the board you buy when you have no idea what you want to do, but you want to keep all your options open. It has a ridiculous amount of driver slots, hotend slots (!!!!), sensors…and just about everything you need short of the ability to make toast.

You will probably need to compile your own marlin for it or whatever, klipper, you get the idea – or if not, look those up, you’ll need to before you try to fit this.

Also, nice duck.

Takes quite a bit of learning to get marlin compiling. it prints very well and it’s much more quiet when printing with the tmc2208 drivers.

Using this in a V-Core 3 with Klipper and it works fantastic

This board has been very well reviewed on YouTube, so check those out.

I’m using it to drive a RatRig VCore 3 hooked up to a Raspberry Pi running klipper.

It’s easy to flash, supports multiple fan voltages, all the endstops and probes needed, lots of steppers.

Recommended for a higher end printer build.

his is the octopus v1.1 3d printer control board, a board designed for advanced user, to enhance the 3d printing experience; it supports 8 stepper drivers, besides the basic x, y, z, e; 4 extra stepper drivers could be used to add 4 extra extruders to make it a multi-extruder printer, print up to 5 colour in a single job!

i’ve been an ender 3 user for a year, and many user upgraded with octopus board, i’ve seen the result was amazing, ordered it to try it myself, i found there are loads of good tutorial from the web to follow

the board came in a very nice packaging, with a usb-c cable and extra 12 jumpers, the board is well built and feel very solid, i was so overwhelmed by loads of socket interfaces in such a small board

this board run best with marlin 2.x.x firmware, which could be downloaded from the github, and edit / compile with visual studio code, before adding more hardware, there is a tool called pronterface to verify if the firmware is properly installed and running, i’m still struggling about how to put things right, it’s much more difficult than i expected, definitely not plug and play

lastly, i’m mounting this board to existing ender 3 printer frame, and from the tutorial they would fit perfectly, there are quite a few 3d model options from the web, but the first thing i need to do is complete my setup

all in all, i’m happy with this product, just the setup is too complicated for beginner even i have over a year to maintain components of my own ender printe

This board is definitely not for beginners. There are no instructions in the box but the company has provided downloads online (see link in the listing above). My partner has been tinkering around with it and he definitely still hasn’t mastered it, or understood all of it, but he feels it has potential.

This 3D printer mainboard looks interesting. It comes with a lot of options and several interfaces. When I received it, it was very well packed. The package includes board jumpers, a USB lead, and a rubber ducky. But the problem that I have faced is that it has no instructions.

And I do not know where I can find information about it. That’s why I consider it a great drawback of this product. So I feel it cannot be tried or tested easily. Therefore, I would not recommend it for the beginners like me. Because it is hard to install.

I will start off by saying changing the stepper motor driver jumpers is a massive pain. Each section has so many jumper leads , I would keep putting the jumper on lead below a lot of times. But despite this struggle this is a good board.

It is probably due to my lack of understanding with the jumpers. I think the Bottom line is that this board is for advanced users. If you are not comfortable figuring out wiring and poking around the source code, you should find someone who is.

Best thing about this board is that they provide the schematic, so at least I can figure stuff out myself. There are a few YouTube videos that may help too! Just have a look before-hand as it may give you a little peace of mind.

Overall a solid board, just not an easy install for a beginner.

I don’t have a working printer yet, but that’s not a reflection on the board, what bits of testing I’ve done with it have been pretty straightforward and have worked so I’m happy!

I also really like the duck!

We have the board and 2209 steppers. Absoloutley amazing and with the option to add more extruders to the ender 5. What’s not to love. Well done Big tree tech. Though it should have been called the krake

Bought one but was dead on arrival. Replacement works great although am still ironing out a few bugs.

Using Marlin 2.0 firmware with a min & max endstop for each axis and 2x filament runout sensors on a multi stepper mixing hotend. When everything works it’s awesome and amazingly silent, but.. that’s with TMC stepper motor drivers. With A4988’s I could never get it to work properly.

from time to time, after it’s been working fine the optical sensor endstops will simply stop working, no rhyme or reason. Am continuing to work through bugs like this. also Marlin / Klipper etc. can only be flashed using the micro SD card, no direct programming from your PC like other cards (GT2560 for example)

Suggest using a stepper saver if you move your axis around by hand to prevent EMF interference killing the stepper drivers, but other than a few niggles (which are likely my getting to grips with the new board) it’s a great board with a ton of features and is infinately configurable.

lastly, a warning to anyone who thinks this is a simple upgrade to your existing board.. all printers differ, as does the kit installed on them. for this to work in your printer, it’s likely you’ll need to be able to solder, use a multi meter for voltage and continuity, re-wire stepper motor cables, re-wire sensor cables (steppers often need AABB or ABAB, sods law your’s will be wrong, sensors often have VSG one end and VGS the other, but yours may well be VGS to VGS for example) not to mention needing to set the current correctly on each stepper motor driver and then code the changes into Marlin or Klipper (configuration.h, configuration.adv, pins.h all require modification depending on what your doing with it.)

if your able to do all this then you won’t be dissapointed!